Combined anti-lightning shunt bar

A technology of lightning protection and shunt strips, which is applied in the installation of emergency protection circuit devices, electrical components, and cables for limiting overcurrent/overvoltage, and can solve the problem of space tolerance, lightning protection, and radome repair and other issues to achieve the effect of saving assembly time, simplifying the process, and improving the effect of lightning protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is further described:

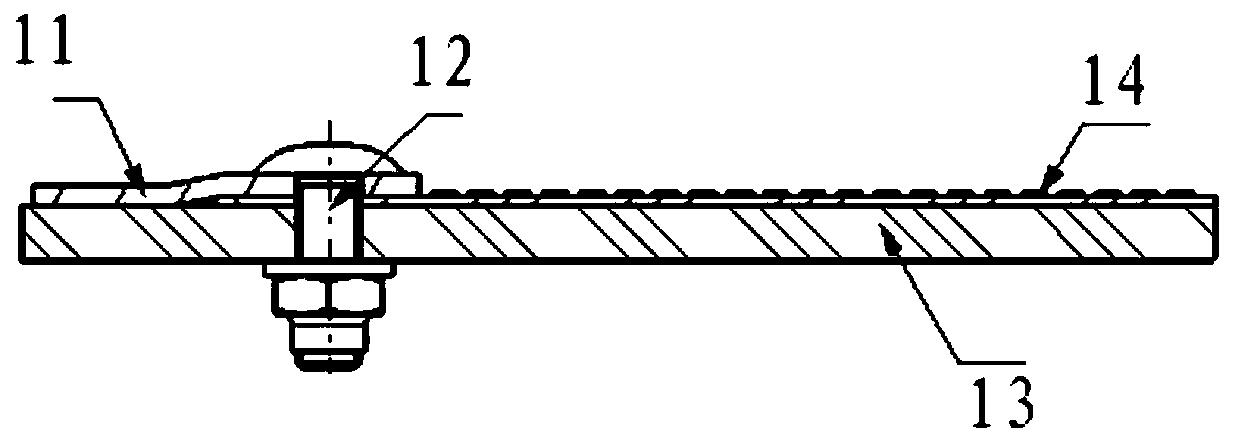

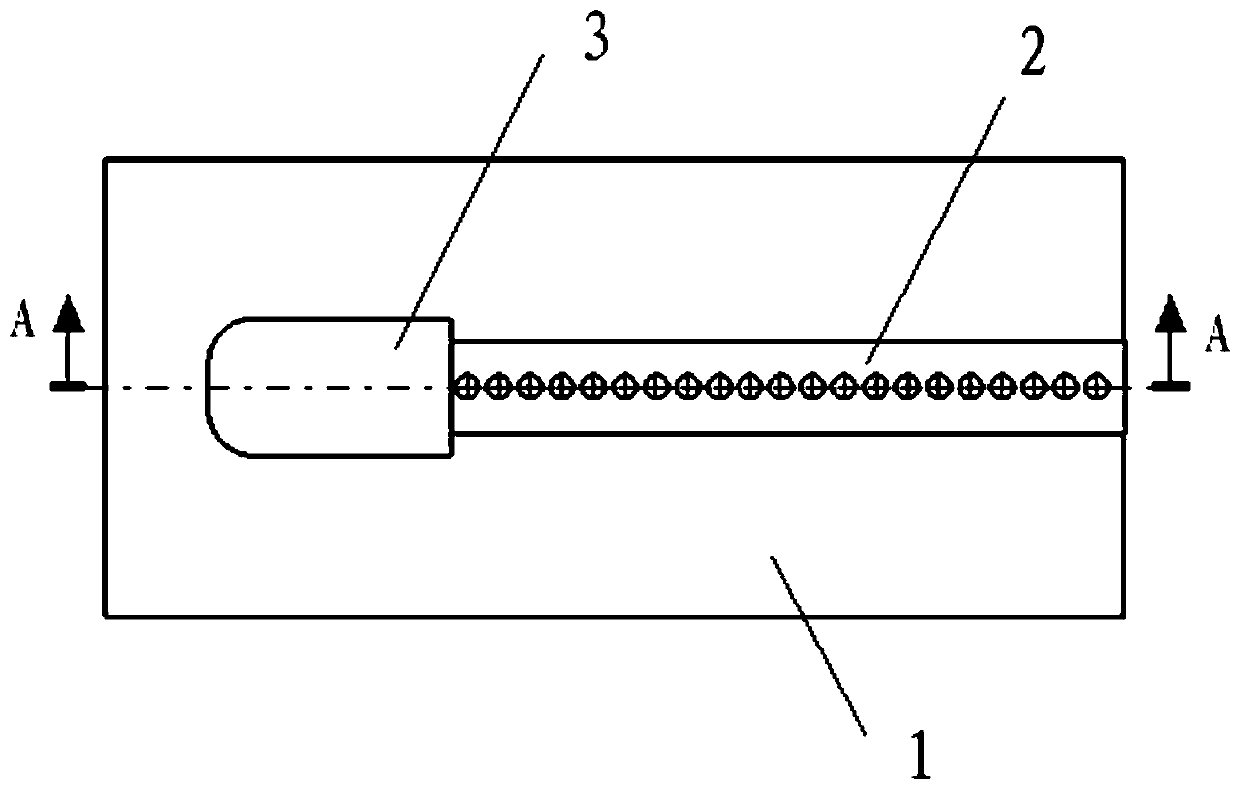

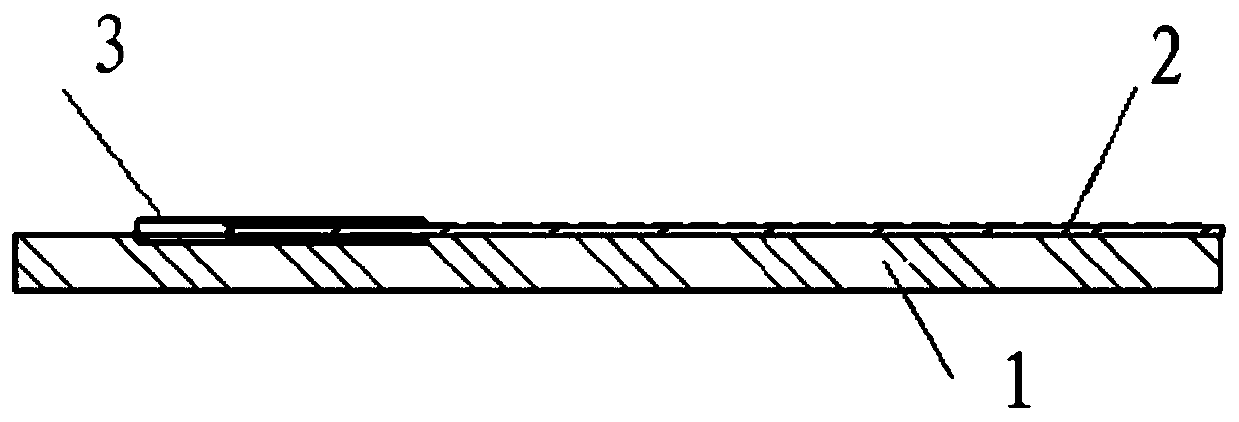

[0016] figure 2 , image 3 , Figure 4 As shown, a combined lightning protection shunt strip includes a button-type lightning protection shunt strip 2 and an electrical lap joint 3; the electrical lap joint 3 forms a groove, and the lightning protection shunt strip 2 is inserted into the recess In the groove, it is fixedly connected with the electrical lap joint 3 to form a whole. The distance between the groove entrance end surface and the first button of the button-type lightning protection shunt strip is not more than 0.5mm, and the gap between the groove and the lightning protection shunt strip 2 It should be within the range of 0.2 mm to 0.5 mm. The depth of the lightning protection shunt strip 2 inserted into the groove is not less than 9 mm. 1 surface. The material of the electrical lap joint 3 is made of aluminum or copper; the electrical lap joint 3 and the lightn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com