Rotary pressure maintaining coring method for ocean drilling

A rotary and coring technology, which is applied in the direction of undisturbed core extraction, underwater drilling, earth square drilling, etc., can solve the problems of low success rate of coring, affecting coring efficiency, high construction risk, etc. Heart success rate, simple and convenient operation, fast and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

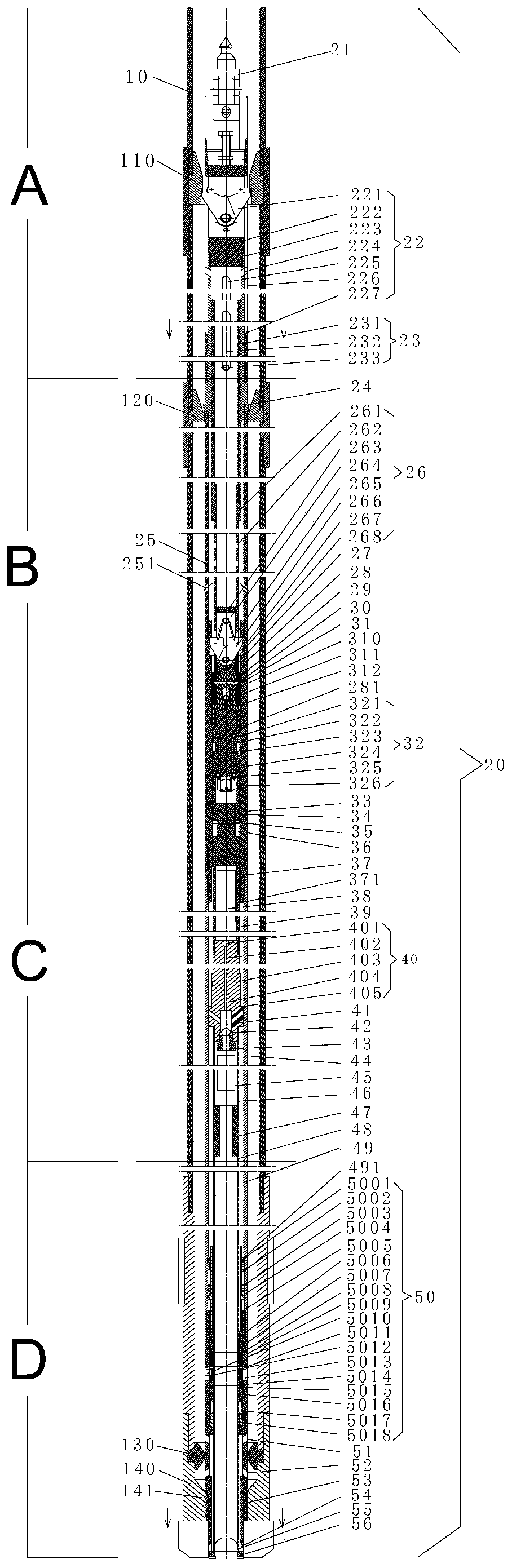

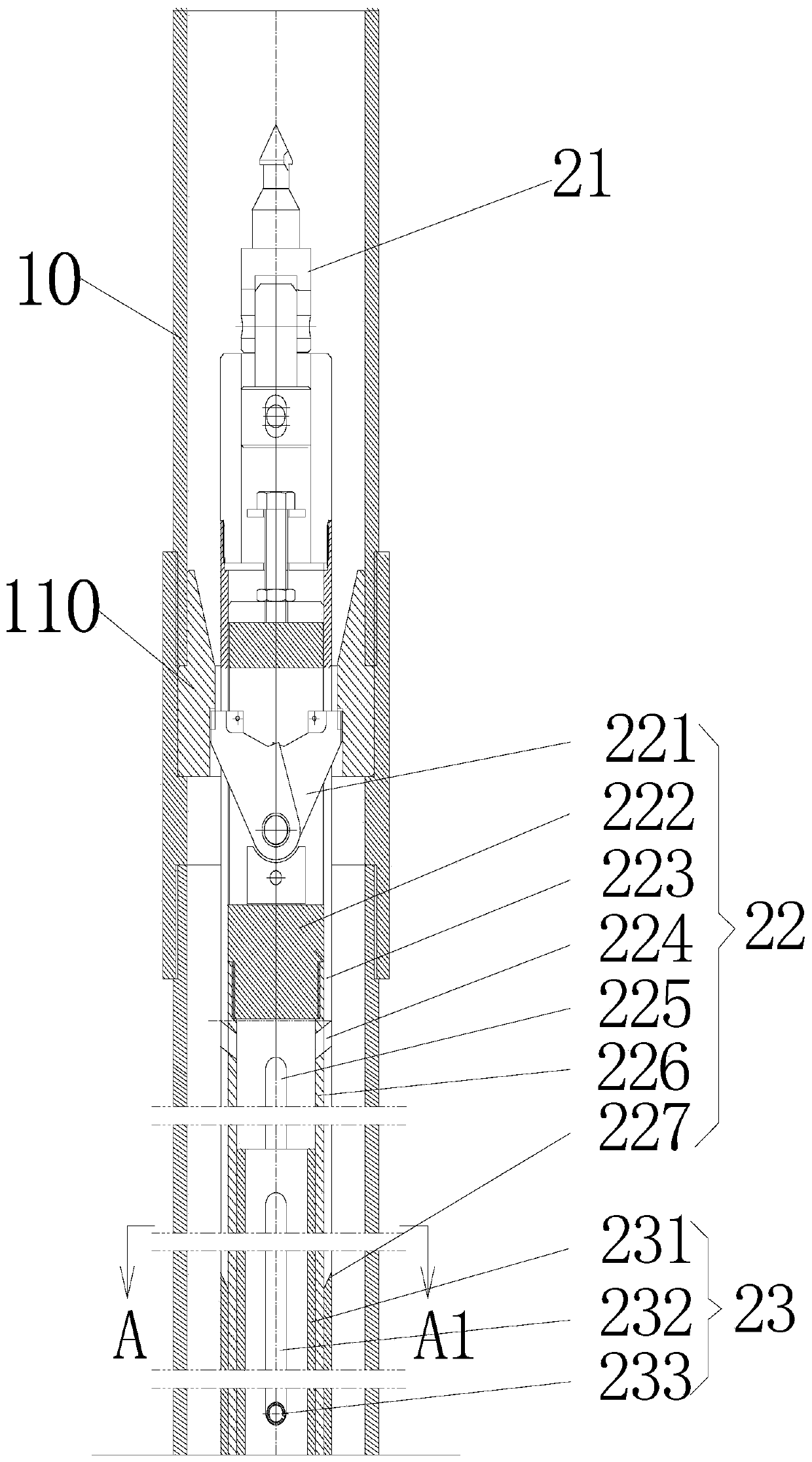

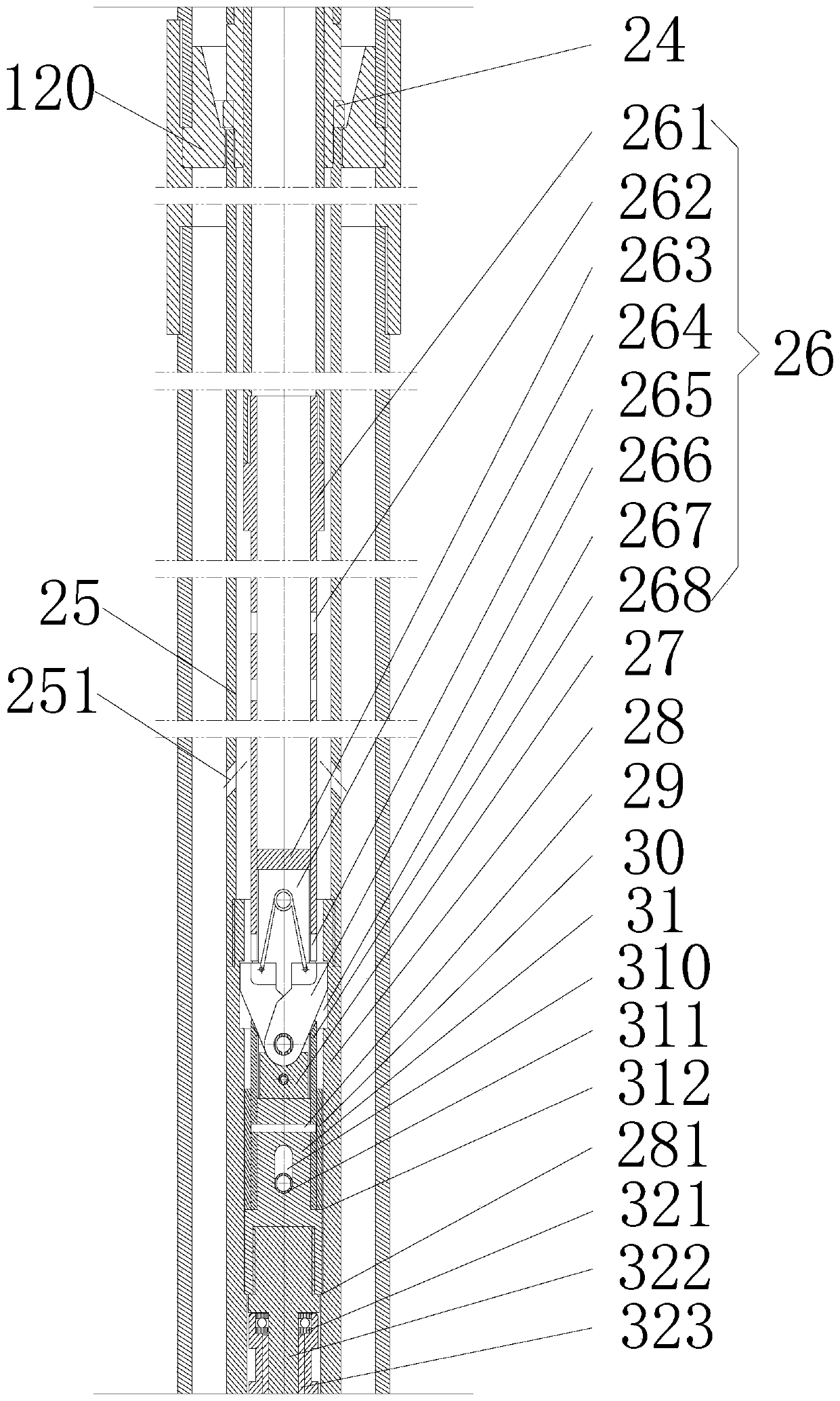

[0059] Such as Figures 1 to 21 shown, including the following steps:

[0060] 1) Connect the fishing spearhead 21 through an overshot (not shown in the figure), and put the inner pipe assembly 20 into the outer pipe assembly 10 at the bottom of the hole. Disconnect the overshot from the spearhead and retrieve the overshot to the rig surface;

[0061] 2) After the drill pipe is connected to the drilling rig, the drilling rig synchronously drills the inner pipe assembly 20 and the outer pipe assembly 10 to the bottom of the well formation through the drill pipe, and keeps the cartridge a 221 of the cartridge mechanism 22 and the cartridge suspension mechanism 26. The cartridges b 266 are all in the open state, and keep the axially fixed outer pipe bit 140 and the middle pipe bit 56 in contact with the bottom of the well for rotary coring. The shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com