Anti-pilling and anti-friction resin finishing agent

A resin finishing and resin emulsion technology, applied in fiber treatment, dry cleaning fiber products, plant fibers, etc., can solve the problems of single function of finishing agent and poor use effect, and achieve good appearance and flatness, improved strength, and stable shrinkage performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

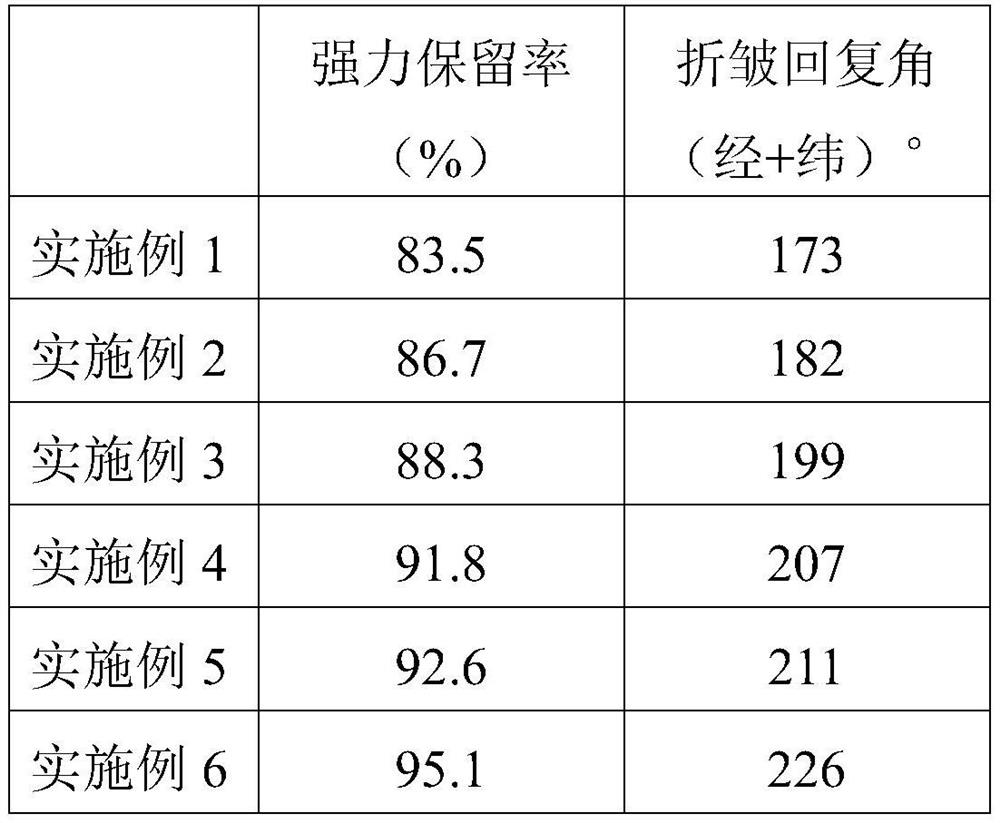

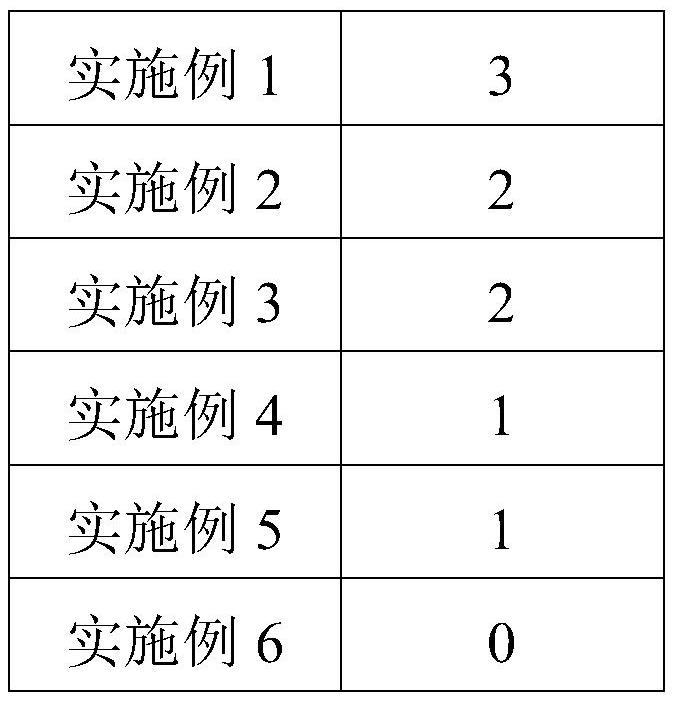

Embodiment 1

[0057] A preparation process for a yarn-dyed fabric with good handle, comprising the following steps:

[0058] P1 weaving: warp yarn and weft yarn are woven into gray cloth by conventional technology; the warp yarn is a pure white cotton yarn with a specification of 11.67tex, and the weft yarn is a green cotton yarn with a specification of 11.67tex;

[0059] P2 singeing: the gray cloth is singed according to the conventional process, the singeing temperature is 800°C, the singeing speed is 110m / min, the singeing level is 3, and the singeed gray cloth is obtained;

[0060] P3 desizing: put the singeed gray cloth in the desizing finishing solution at 50°C for 8 hours, then remove the gray cloth and wash it with water at 60°C for 20 minutes. Gray cloth after sizing; the formula of the desizing finishing solution is: amylase 12g / L, penetrant 5g / L, industrial salt 6g / L, and the balance is water;

[0061] P4 mercerizing: immerse the gray cloth after desizing in an aqueous solution ...

Embodiment 2

[0072] A preparation process for a yarn-dyed fabric with good handle, comprising the following steps:

[0073] P1 weaving: warp yarn and weft yarn are woven into gray cloth by conventional technology; the warp yarn is a pure white cotton yarn with a specification of 11.67tex, and the weft yarn is a green cotton yarn with a specification of 11.67tex;

[0074] P2 singeing: the gray cloth is singed according to the conventional process, the singeing temperature is 800°C, the singeing speed is 110m / min, the singeing level is 3, and the singeed gray cloth is obtained;

[0075] P3 desizing: put the singeed gray cloth in the desizing finishing solution at 50°C for 8 hours, then remove the gray cloth and wash it with water at 60°C for 20 minutes. Gray cloth after sizing; the formula of the desizing finishing solution is: amylase 12g / L, penetrant 5g / L, industrial salt 6g / L, and the balance is water;

[0076] P4 mercerizing: immerse the gray cloth after desizing in an aqueous solution ...

Embodiment 3

[0089] A preparation process for a yarn-dyed fabric with good handle, comprising the following steps:

[0090] P1 weaving: warp yarn and weft yarn are woven into gray cloth by conventional technology; the warp yarn is a pure white cotton yarn with a specification of 11.67tex, and the weft yarn is a green cotton yarn with a specification of 11.67tex;

[0091] P2 singeing: the gray cloth is singed according to the conventional process, the singeing temperature is 800°C, the singeing speed is 110m / min, the singeing level is 3, and the singeed gray cloth is obtained;

[0092] P3 desizing: put the singeed gray cloth in the desizing finishing solution at 50°C for 8 hours, then remove the gray cloth and wash it with water at 60°C for 20 minutes. Gray cloth after sizing; the formula of the desizing finishing solution is: amylase 12g / L, penetrant 5g / L, industrial salt 6g / L, and the balance is water;

[0093] P4 mercerizing: immerse the gray cloth after desizing in an aqueous solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com