Tool film plating rotating frame device of high-vacuum multi-arc ion film plating machine

A multi-arc ion, high vacuum technology, applied in ion implantation coating, vacuum evaporation coating, sputtering coating and other directions, can solve the problems of inconsistency, gear stuck coating time, etc., achieve simple structure, simple device structure and , The effect of the device structure is efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

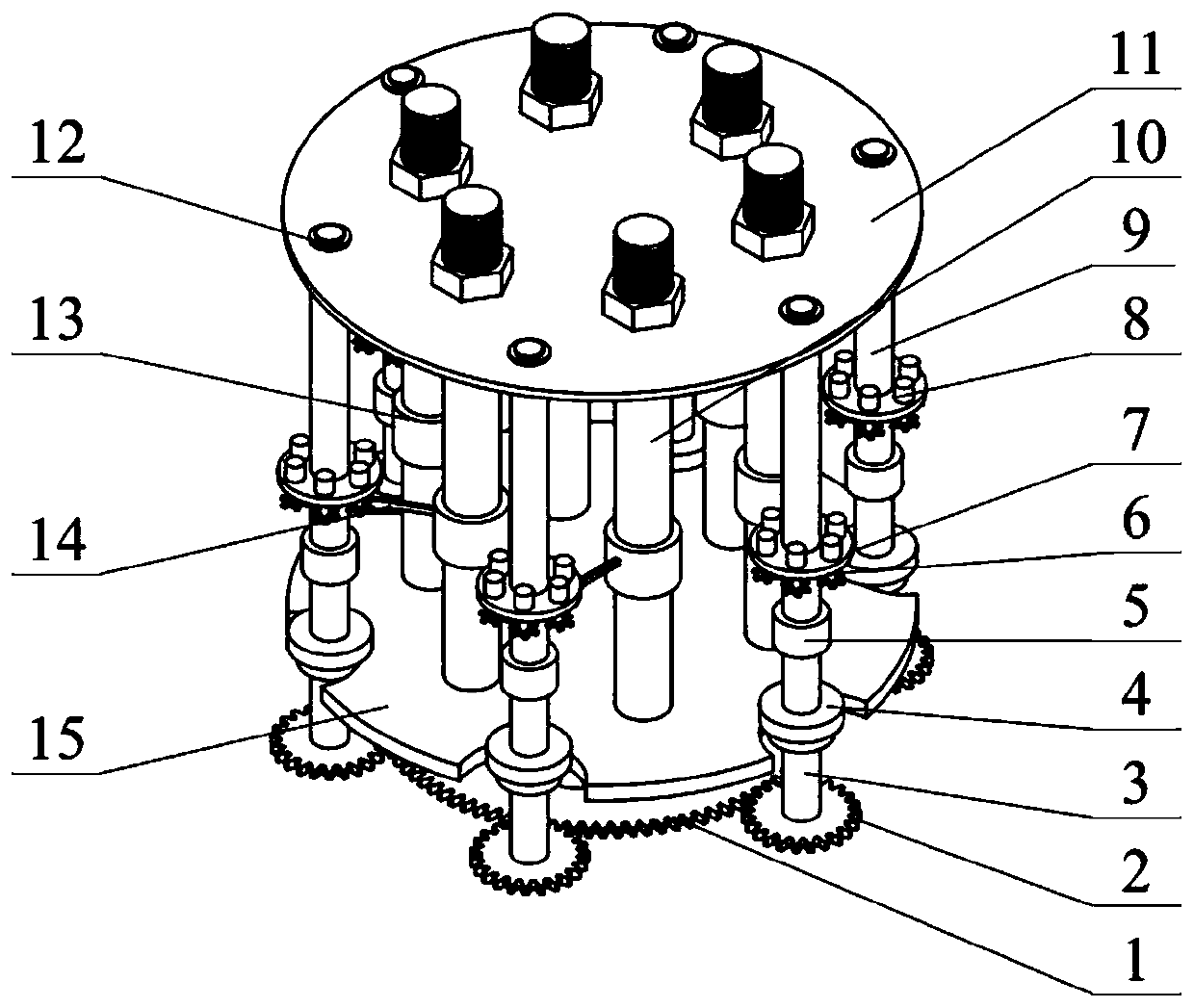

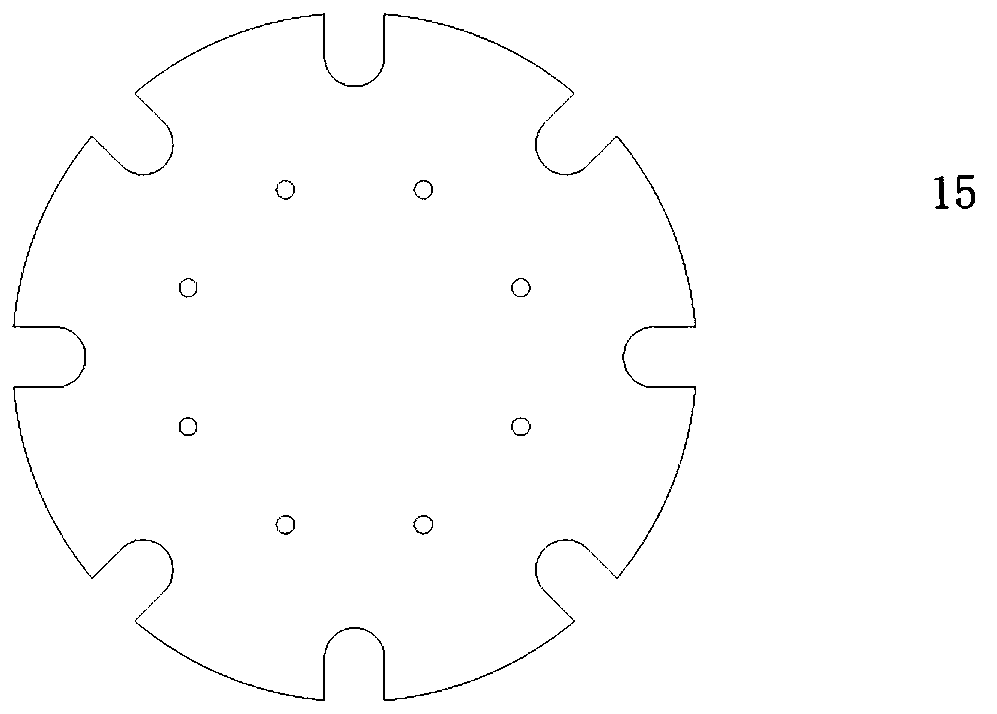

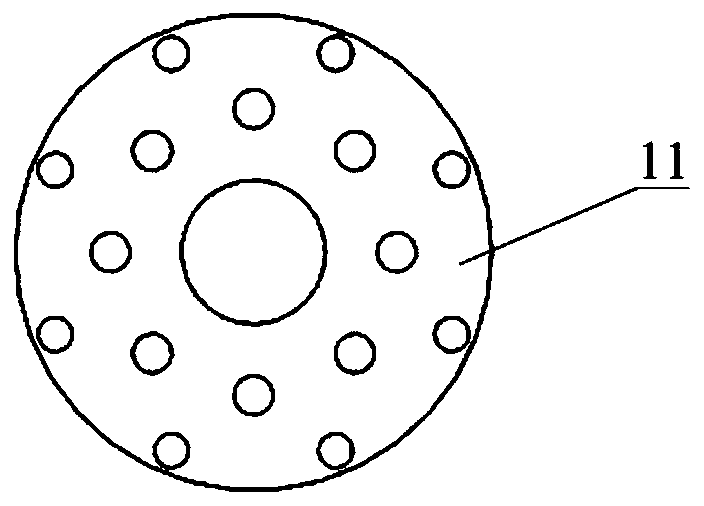

[0024] The tool coating turret device structure of a high vacuum multi-arc ion coating machine provided by the present invention is as follows: figure 1 As shown, the lower turntable 15 and the upper turntable 11 (as shown in Fig. image 3 shown), the lower turntable 15 (as figure 2 As shown), there is a U-shaped through hole with a circle of center symmetry at the edge position, and a lower bearing 4 is arranged along the vertical direction of the U-shaped through hole. The lower bearing 4 is connected to the lower transmission shaft 3, and the lower end of each lower transmission shaft 3 is nested with The pinion 2, the pinion 2 meshes with the fixed large gear 1 located at the center below the lower turntable 3; the lower transmission shaft 3 is connected with an upper transmission shaft 9, and the upper part of the upper transmission shaft 9 is nested and arranged on the workpiece turntable 7; Several uniformly distributed workpiece seats 8 are arranged on the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com