Preparation method of two-dimensional crystal Nb2CTx nano material

A nanomaterial, two-dimensional crystal technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high risk, difficult to store, strong irritation of hydrofluoric acid, etc. Gentle process, environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 1gLiF into the corrosion bottle, measure 10mL 12mol / L hydrochloric acid, pour it into the corrosion bottle, and then add 1g Nb 2 Slowly add the AlC raw material into it, and after the reaction is stable, place it under magnetic stirring at 50°C for 72 hours, wash and centrifuge the product repeatedly with deionized water until the pH value is greater than or equal to 5, ultrasonically disperse for 1 hour, and add 5mL~100mL of water to obtain a concentration of 1 ~30mg / mL of Nb 2 CT x solution, centrifuged and filtered to obtain a monolayer of Nb 2 CT x Thin film material, take bottom solid and dry, obtain described multi-layer two-dimensional crystal Nb 2 C nanomaterials, measuring 2D crystalline Nb 2 CT x The electrical conductivity is 500~3000S / cm.

Embodiment 2

[0024] Weigh 0.99g LiF into the corrosion bottle, measure 10mL 9mol / L hydrochloric acid, pour it into the corrosion bottle, and then add 1g Nb 2 Slowly add the AlC raw material into it, and after the reaction is stable, place it under magnetic stirring at 50°C for 72 hours, wash and centrifuge the product repeatedly with deionized water until the pH value is greater than or equal to 5, ultrasonically disperse for 1 hour, and add 5mL~100mL of water to obtain a concentration of 0.1 ~30mg / mL of Nb 2 CT x solution, centrifuged and filtered to obtain a monolayer of Nb 2 CT x Thin film material, take bottom solid and dry, obtain described multi-layer two-dimensional crystal Nb 2 CT x Nanomaterials, measuring 2D crystalline Nb 2 CT x The electrical conductivity is 2000~4000S / cm.

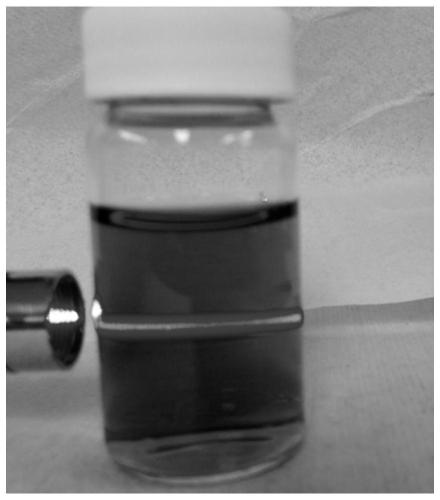

[0025] figure 1 two-dimensional crystal Nb 2 CT x Aqueous solutions of nanomaterials and Tyndall phenomenon;

[0026] figure 2 For the two-dimensional nanolayered crystal Nb 2 CT x Prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com