Marine salt water cooling system with cold bridge preventing function and mounting method thereof

A saltwater cooling and anti-cold bridge technology, which is applied in hull ventilation/heating/cooling, ship components, ship construction, etc., can solve the problems of pipeline or equipment performance degradation, failure to guarantee normal operation, temperature loss, etc., to reduce cold bridges Radiation, avoiding cold bridge phenomenon, reducing the effect of cold bridge transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

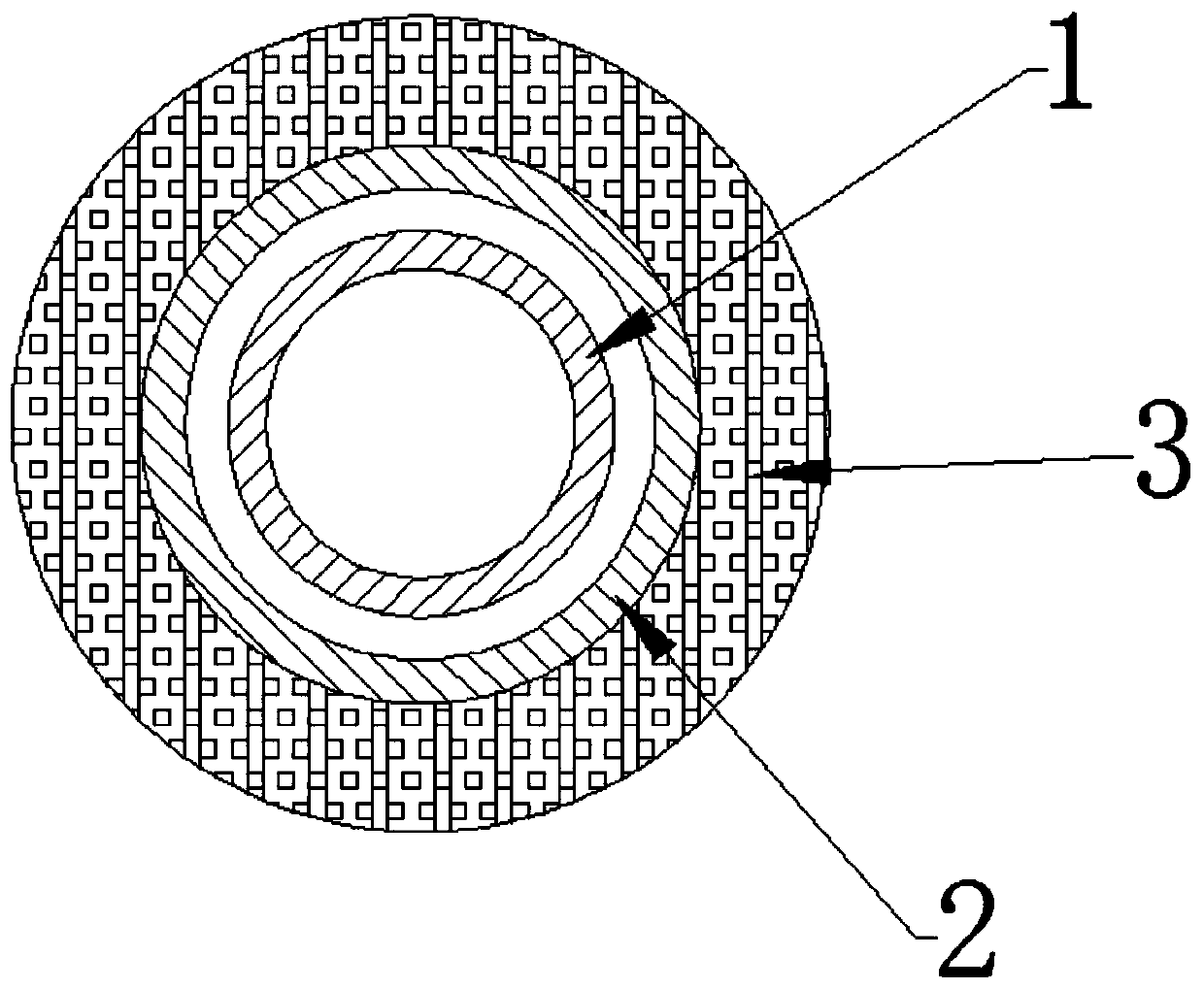

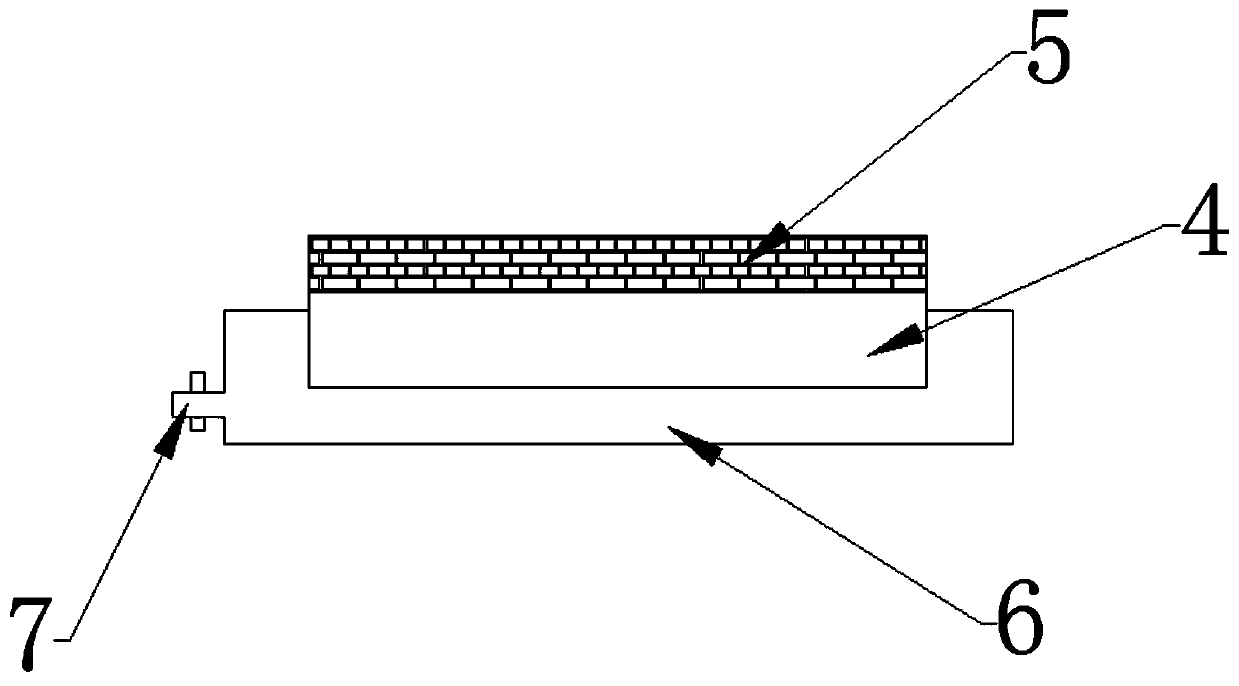

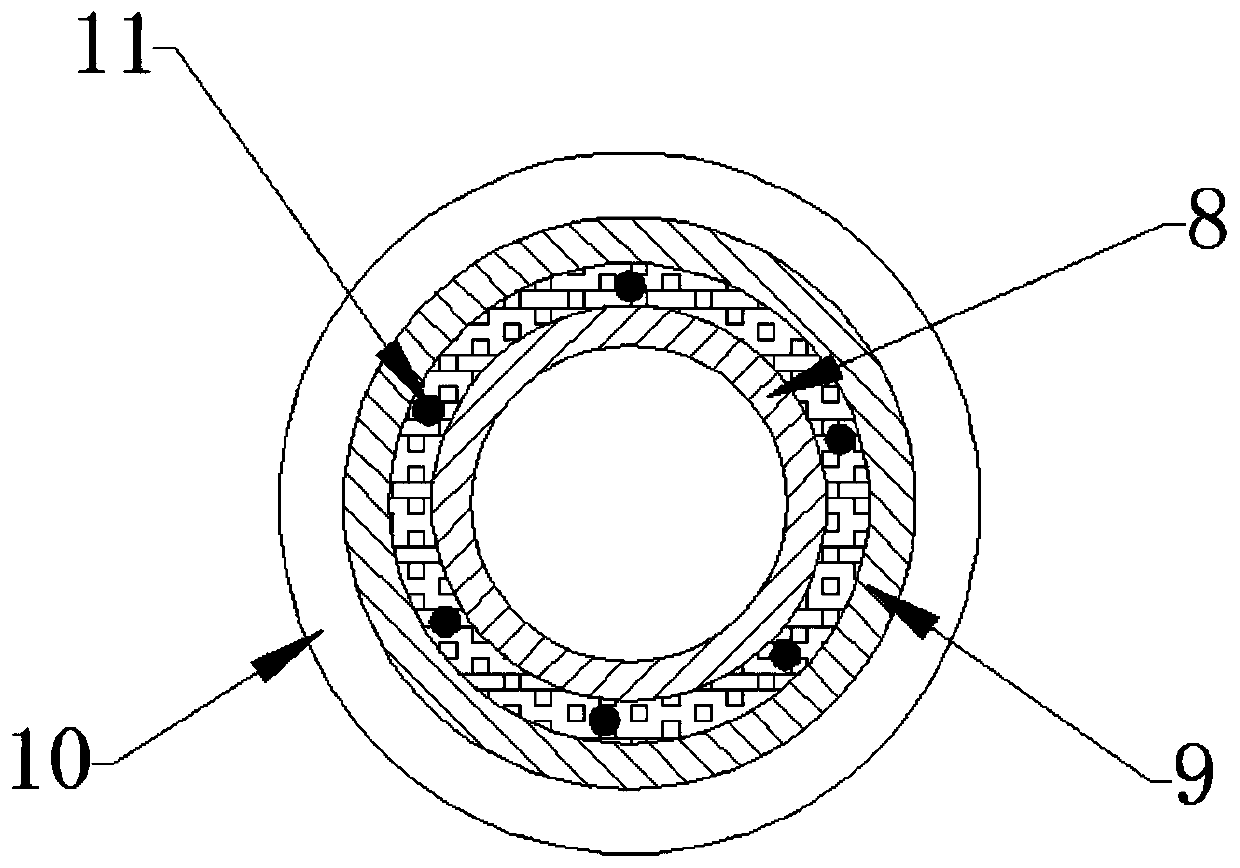

[0032] Such as figure 1 As shown, the present invention is a marine brine cooling system with anti-cold bridge function, which includes a brine cooling compressor unit, a cooling brine pump, a mixed brine pump, a brine transfer pump and an air cooler connected in sequence by pipelines, and also includes a controller. The brine cooling compressor unit, the cooling brine pump, the mixed brine pump, the brine transfer pump and the air cooler are all equipped with a hermetic casing, and the pipeline includes an inner pipe 1 and an outer pipe 2 arranged concentrically, and the outer casing and the outer pipe 2 are provided with air holes, and electromagnetic va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com