Three-dimensional five-axle 3D laser cutting machine

A laser cutting machine, 3D technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of laser cutting precision reduction, maintain a safe distance between the cutting head and the workpiece, and the large volume of linkage components, to reduce the laser The effect of energy loss, good overall sealing, and shortened optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, embodiments and effect examples, without limiting the present invention.

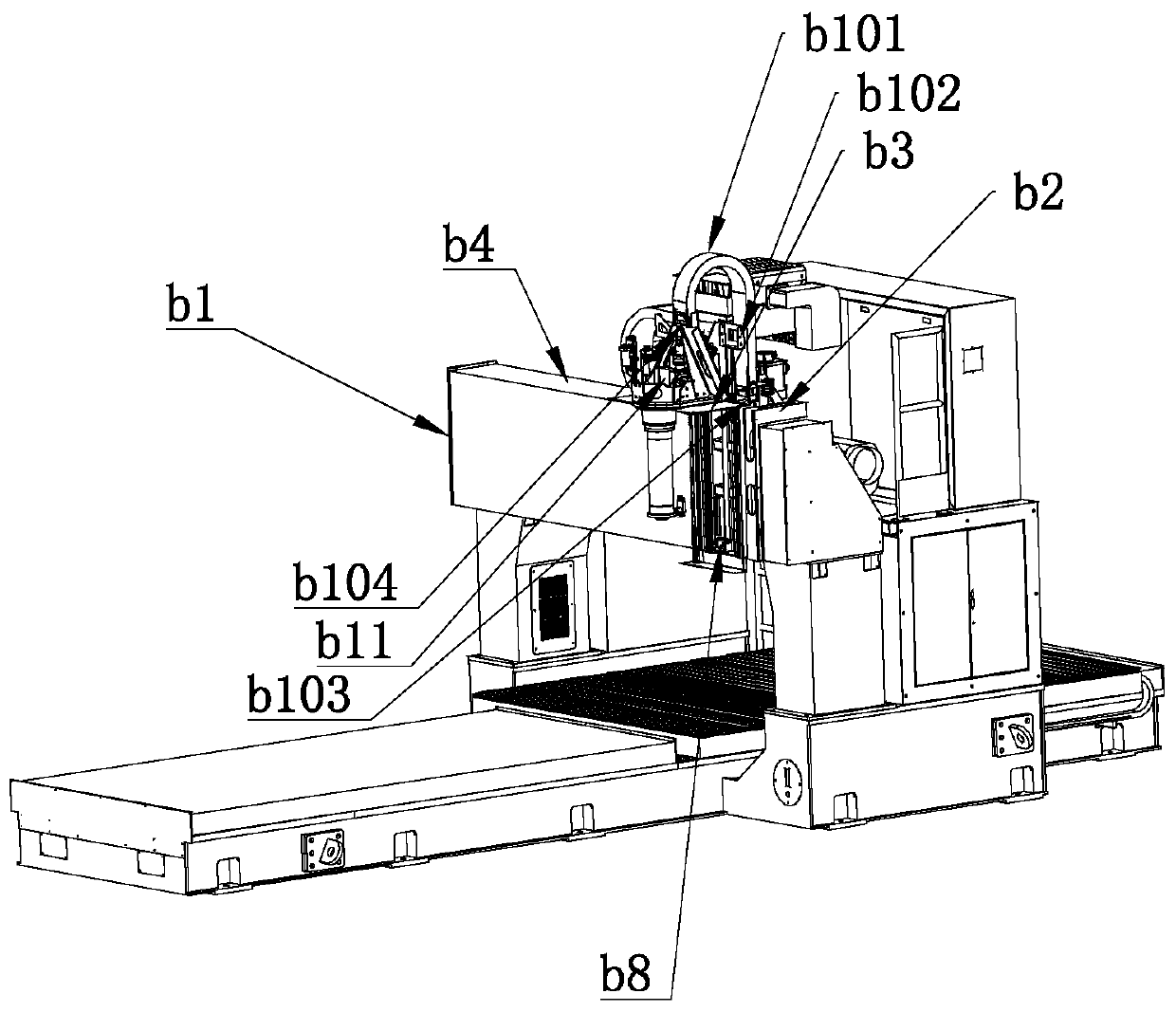

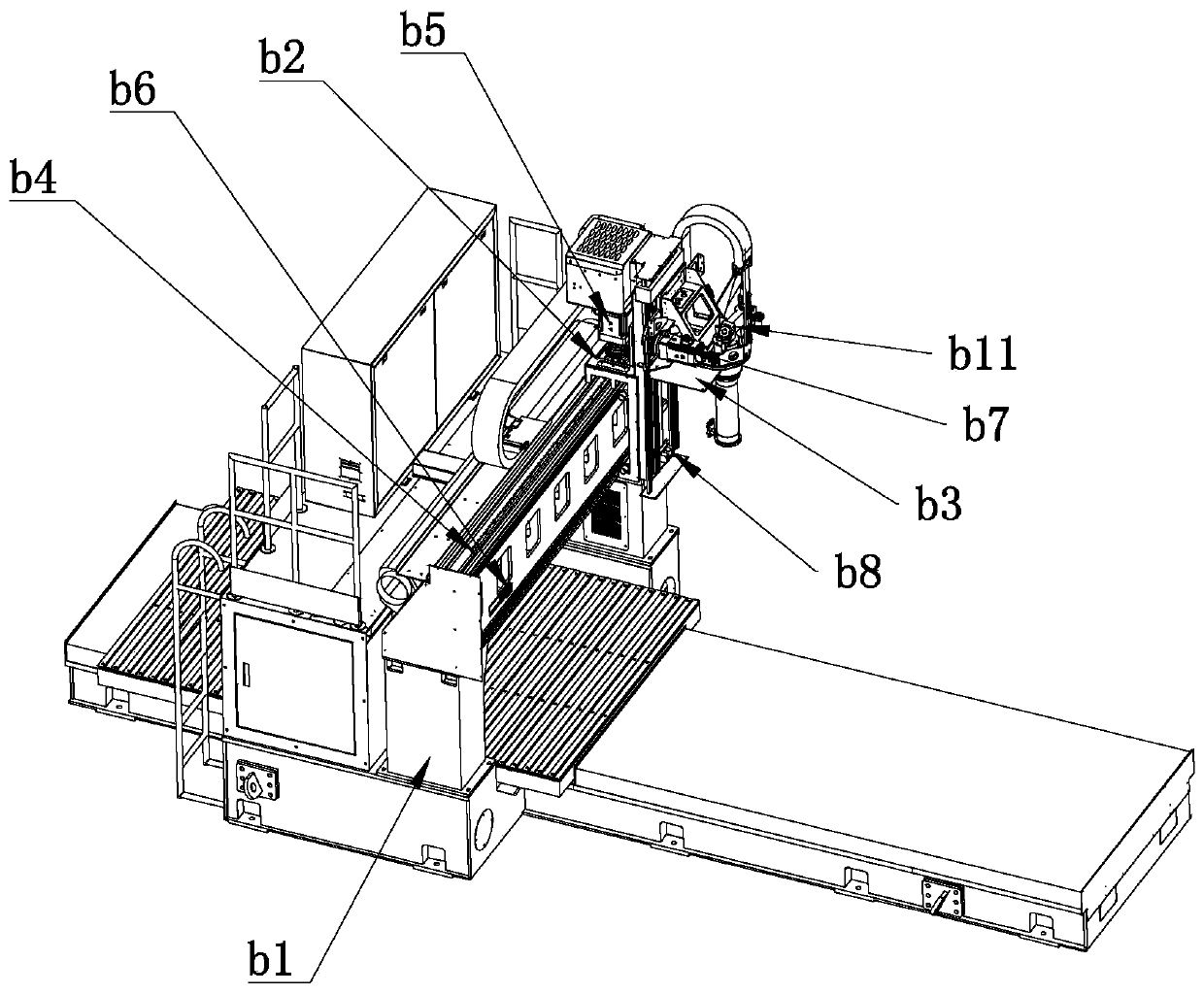

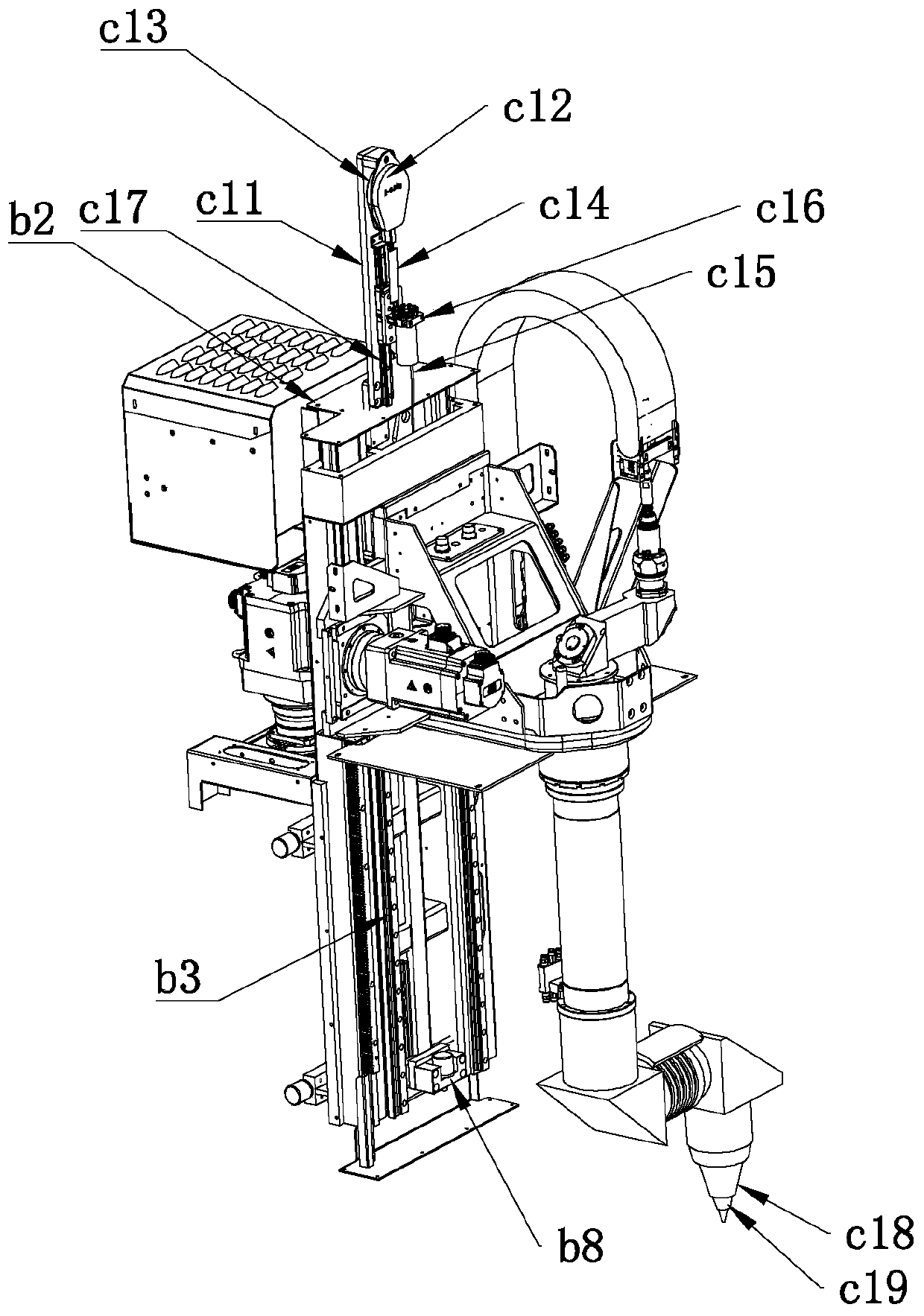

[0033] Such as Figure 1-14 As shown, a three-dimensional five-axis 3D laser cutting machine includes a base a1, a workbench a2, a mounting frame and a cutting head. The workbench a2 is slidably connected to the base a1, and the drive workbench a2 is arranged inside the base a1. A single-axis sliding drive device, the base a1 is provided with a first anti-collision block a3, the first anti-collision block a3 is a position proximity switch, and the first anti-collision block a3 is used to detect the movement of the workbench a2 position, the installation position of the first anti-collision block a3 defines the sliding travel range of the table a2, and the first anti-collision block a3 is coupled with the driving device, and the driving device includes a single-axis sliding direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com