Manufacturing method for honeycomb structure

A manufacturing method and technology of honeycomb structure, applied in manufacturing tools, laser welding equipment, welding/welding/cutting items, etc., can solve the problems of complex production process, unstable quality, low efficiency, etc. Product quality, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The manufacturing method of the honeycomb structure provided by the present embodiment comprises:

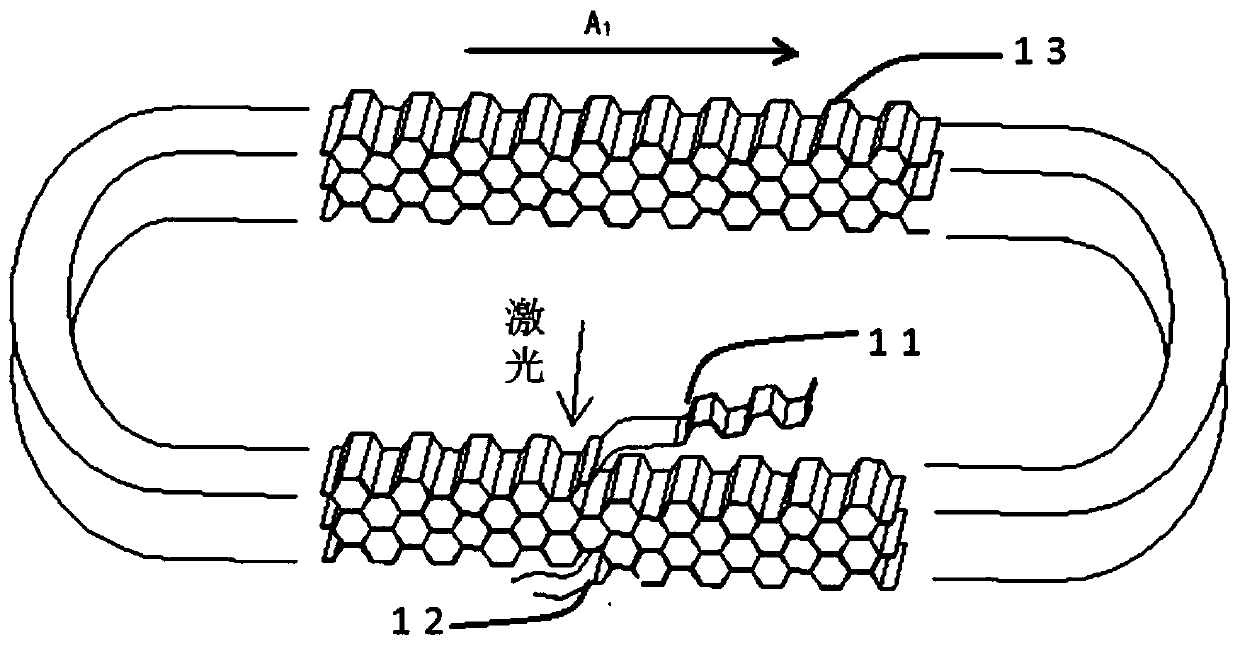

[0050] A continuously formed first corrugated strip is provided, the first corrugated strip has opposite first ends 11 and second ends 12, the first end 11 and the middle of the corrugated strips close to the second end 12 meet to form an annular starting honeycomb core structure, so that the initial honeycomb core structure drives the corrugated belt clockwise along the A 1 Directional circular movement, starting from the intersection of the corrugated strips, the continuous corrugated strips are driven by the initial honeycomb core structure to surround one side of the corrugated strips. The circular motion of the structure, when the continuous corrugated strips are superimposed and passed through the laser position in sequence, the convex surface of the corrugated strips are fixed by laser spot welding, and this cycle is finally processed into a first honeycomb structu...

Embodiment 2

[0052] The manufacturing method of the honeycomb structure provided by the present embodiment comprises:

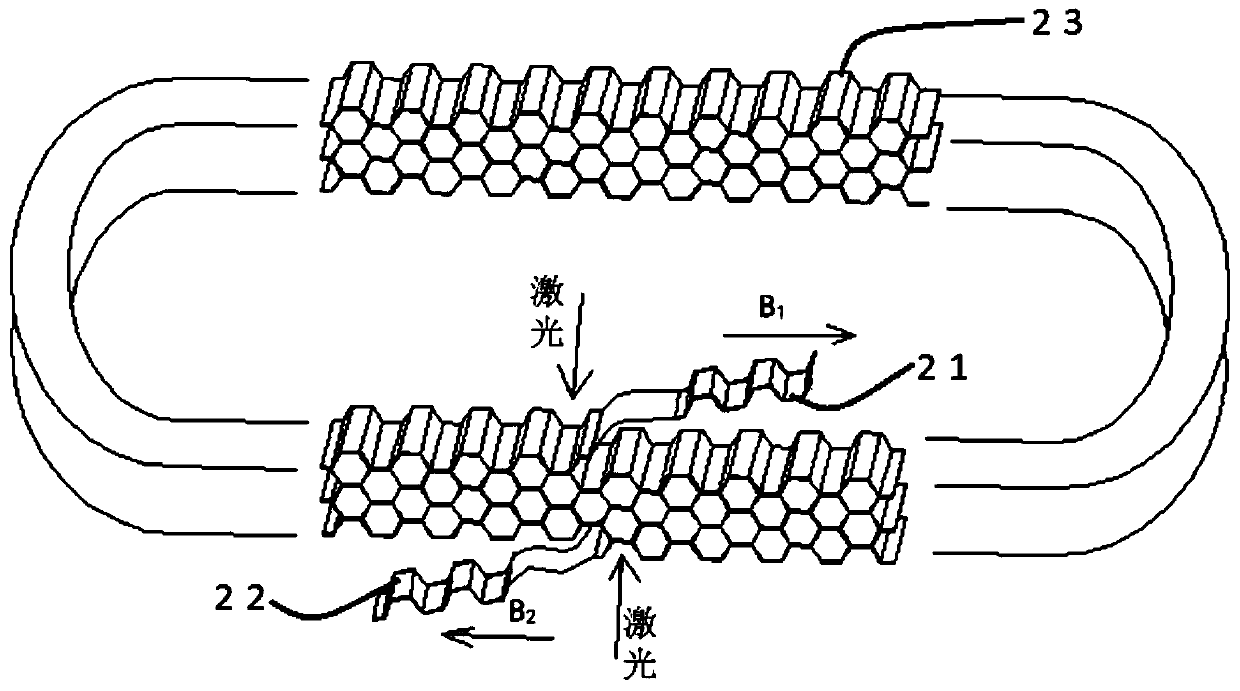

[0053] The second corrugated belt of continuous molding is provided, and the second corrugated belt has opposite first ends 21 and second ends 22, so that two arbitrary positions in the corrugated belt meet to form an annular initial honeycomb core structure, so that the initial honeycomb The core structure remains stationary, and with the intersection of any position as the starting point, the part between the starting point and the first end 21 in the corrugated belt starts from the starting point along the counterclockwise direction B 1 The direction of winding is superimposed on one side of the initial honeycomb core structure in sequence, and the upper laser moves synchronously with the section of corrugated belt, and at the same time makes the part between the starting point and the second end 22 of the corrugated belt move clockwise from the starting point the B 2...

Embodiment 3

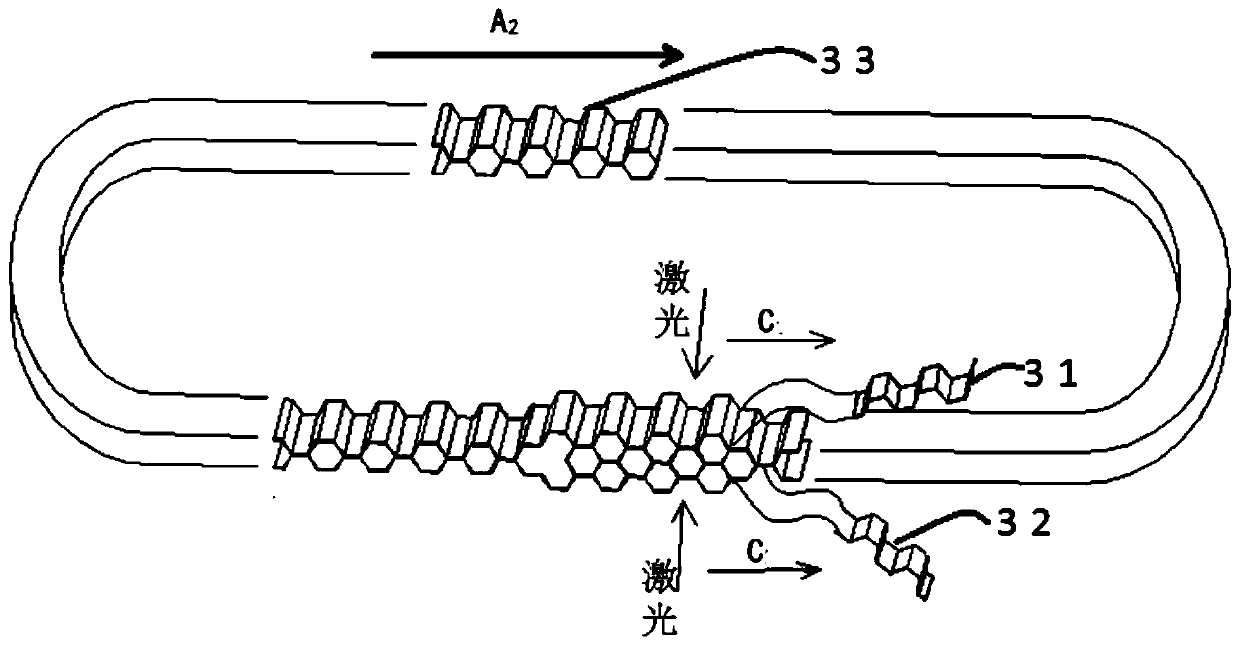

[0055] The manufacturing method of the honeycomb structure provided by the present embodiment comprises:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com