Method for manufacturing 3D printing customized hearing aid

A technology of 3D printing and production method, applied in the direction of improving process efficiency, improving energy efficiency, etc., can solve the problems of poor sound insulation effect, allergic reaction, easy falling off, etc., and achieve the effect of convenient installation, clear sound quality and stable sound transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

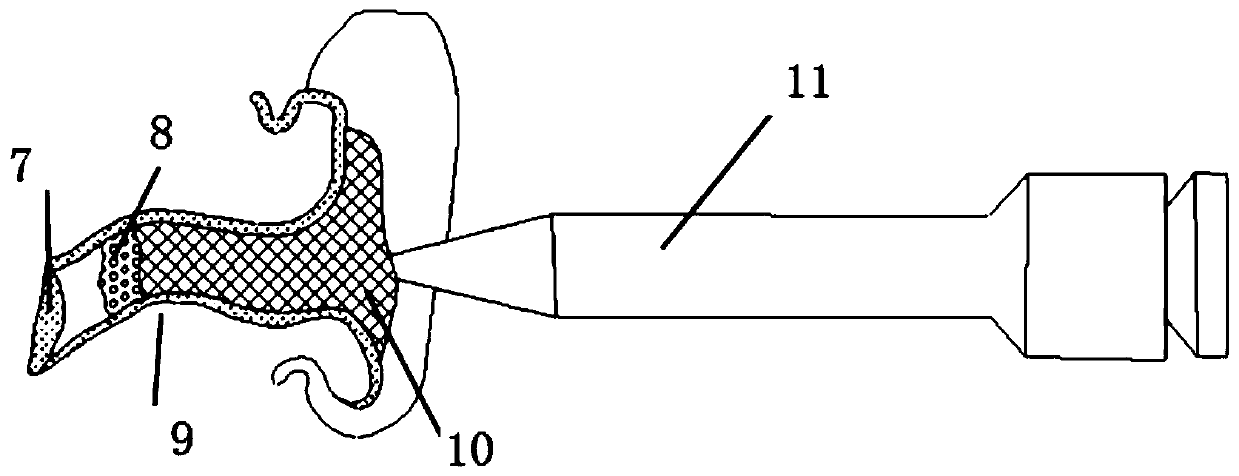

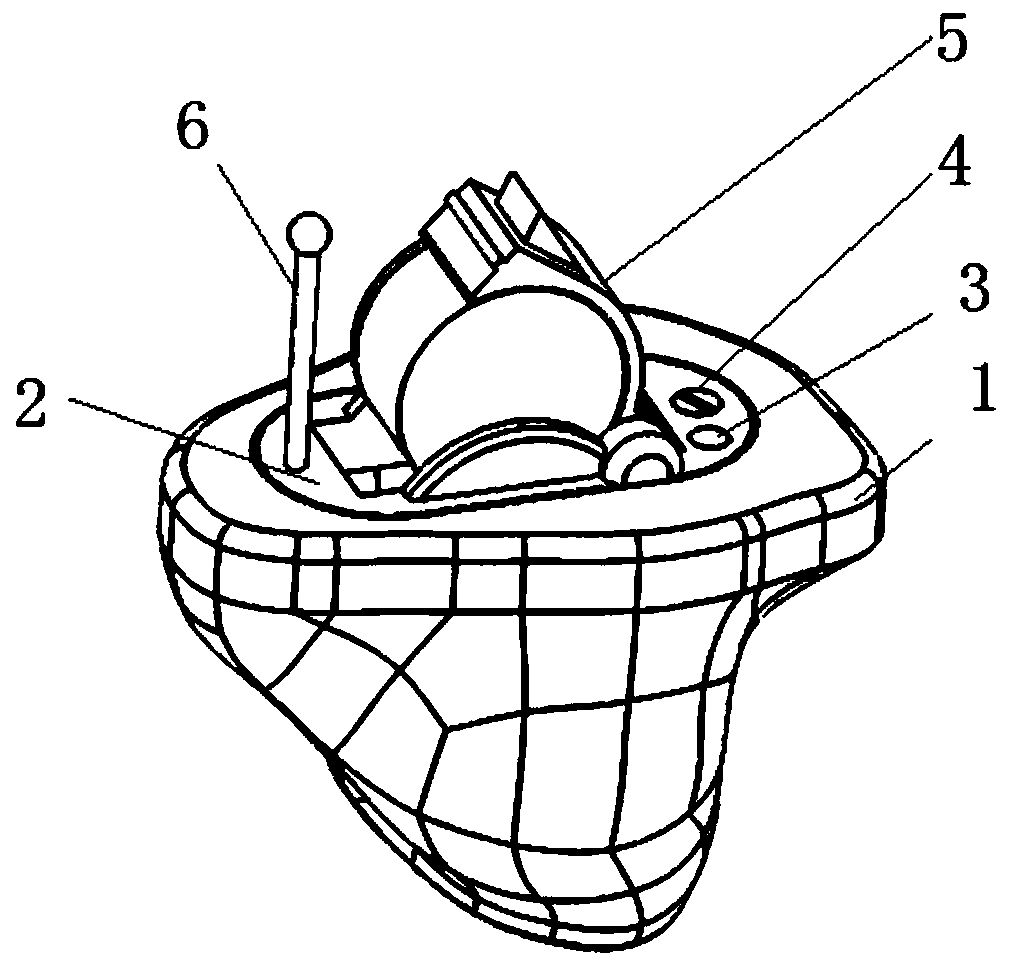

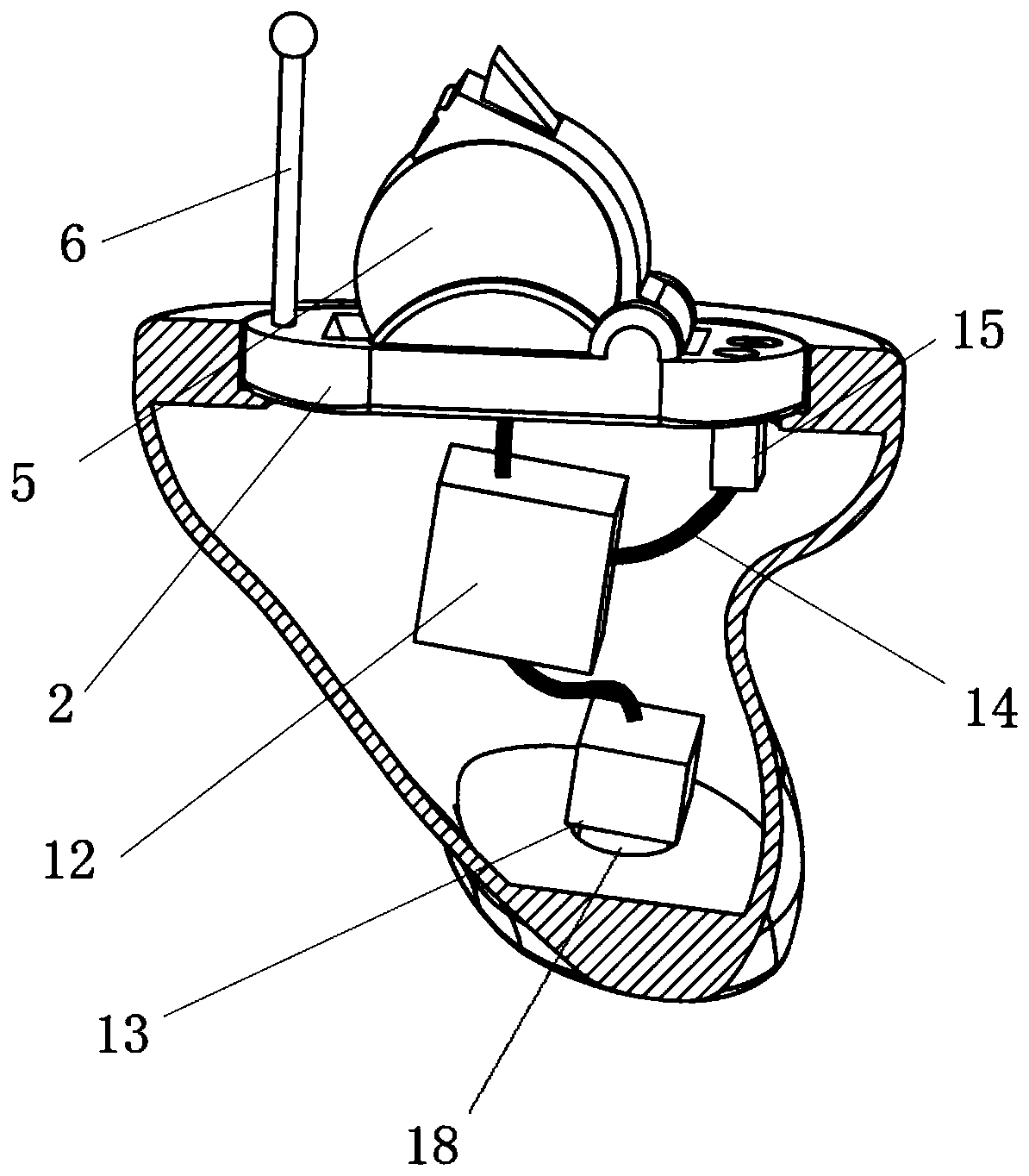

[0037] The hearing aid includes a shell, a cover, and components connected to the shell and the cover. The shell fits the inner cavity of the ear canal of the hearing-impaired person. First, the shell is made, and the medical image data of the hearing-impaired person is reconstructed in three dimensions to obtain a three-dimensional image of the ear canal. Data, and then use 3D software to design and optimize the hearing aid shell according to the reconstructed 3D data. After designing the model, use a 3D metal printer to print it. After the printing is completed, carry out post-processing work. test.

[0038] like figure 1 As shown, the manufacturing steps of the shell are as follows:

[0039] Step 1: Place the ear barrier 1-2mm behind the second bend of the ear canal;

[0040] Step 2: Inject the ear impression paste into the ear canal with a syringe;

[0041] Step 3: Wait for the ear impression paste to harden and take it out;

[0042] Step 4: Use a medical 3D scanner to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com