Pressure controlling valve to be attached to base-mounted change valve

A technology of pressure regulating and switching valves, which is applied in the field of pressure regulating valves and can solve problems such as the inability to use elevators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

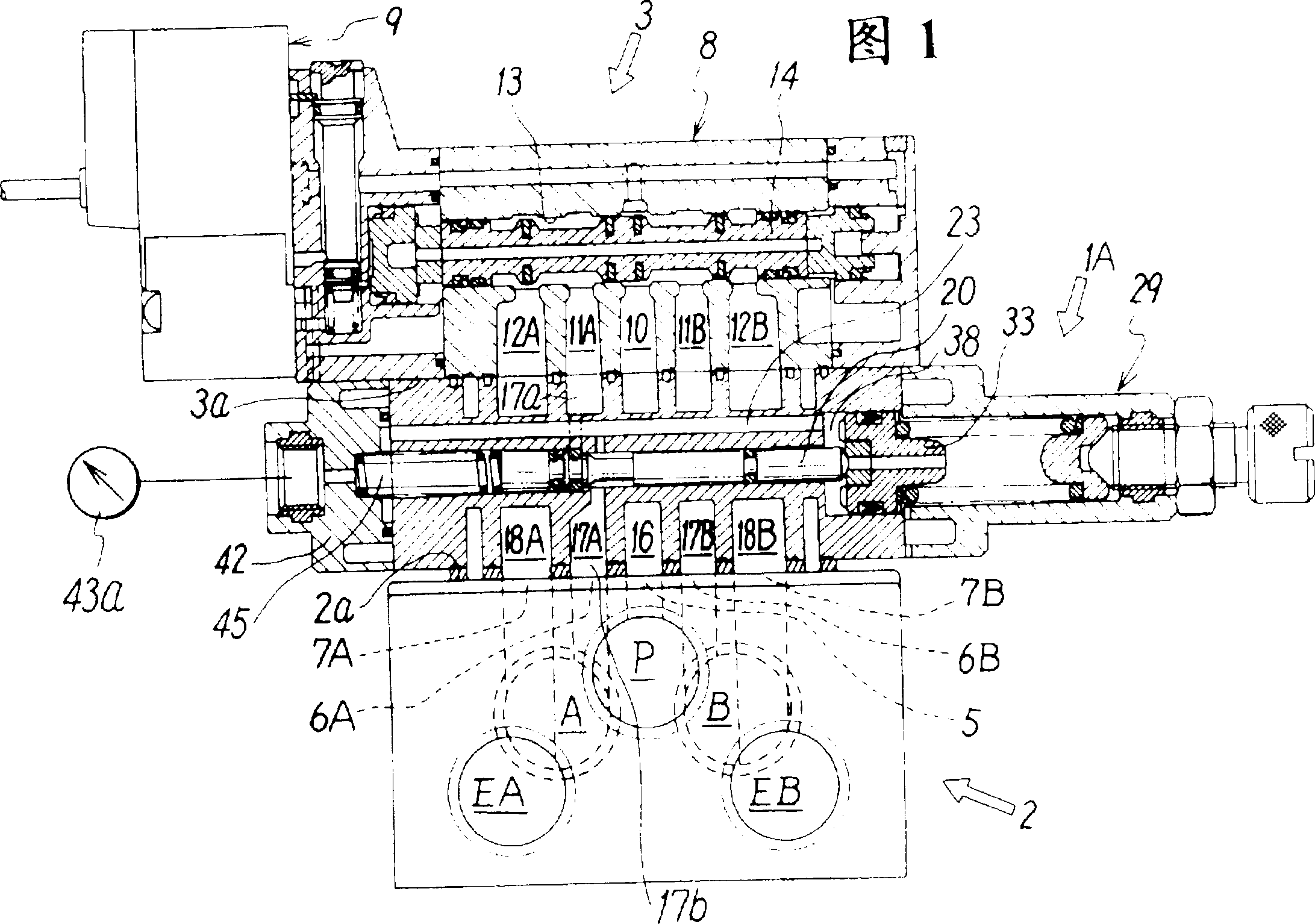

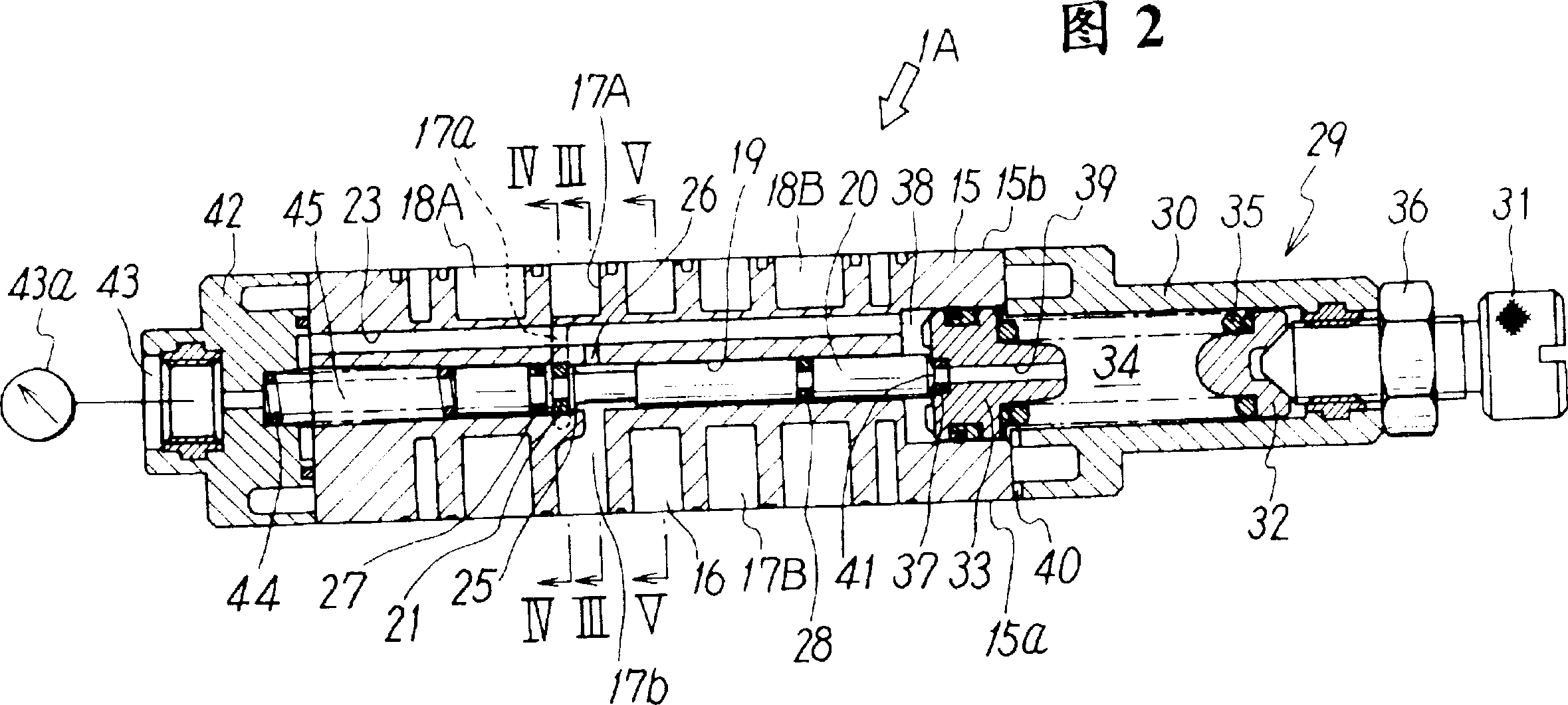

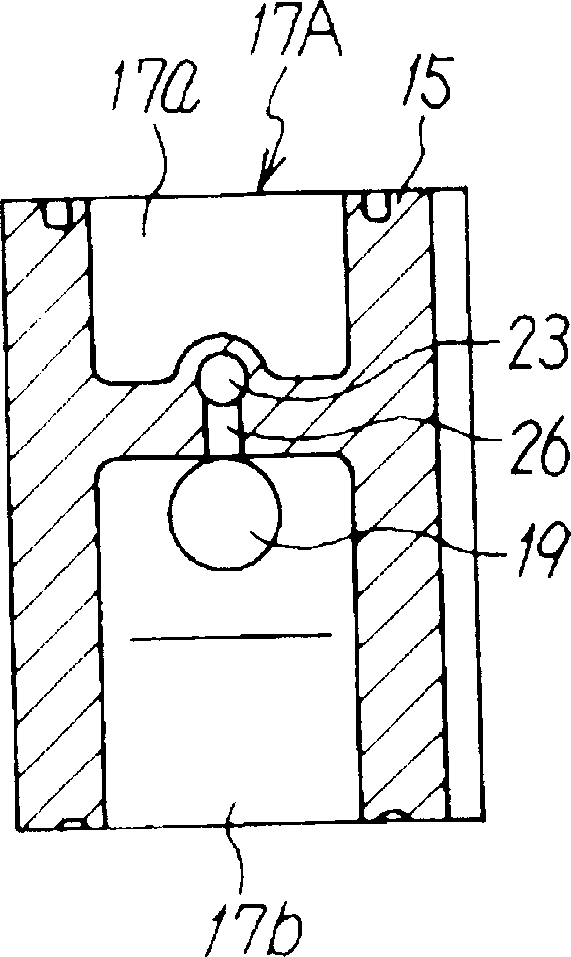

[0041] FIG. 1 shows a state in which a pressure regulating valve 1A according to a first embodiment of the present invention is directly installed between a base 2 and a switching valve 3 . These respective members 1A, 2 and 3 are fixed to each other by appropriate mounting structures such as mounting bolts (not shown).

[0042]The above-mentioned base 2 is a general term for components such as a manifold and a bottom plate with a piping port. It has a structure that can mount one or more switching valves. The base 1 shown in the figure is for mounting one switching valve 3 and Monolithic base used. The base 2 has a compressed air supply port P, a first discharge port EA, and a second discharge port EB on one side, and has a first output port A and a second output port B on the other side. . Also, on the upper surface of the above-mentioned base 2, a flat mounting surface 2a for a pressure regulating valve is provided; on this mounting surface 2a, supply through-holes 5, whi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap