Surface treatment method of stainless steel vacuum container with three-dimensional cloth feeling

A vacuum container and surface treatment technology, which is applied to special surfaces, pretreatment surfaces, and devices for coating liquids on surfaces, etc., which can solve problems such as the inability to meet people's living needs and the single surface color of stainless steel vacuum containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

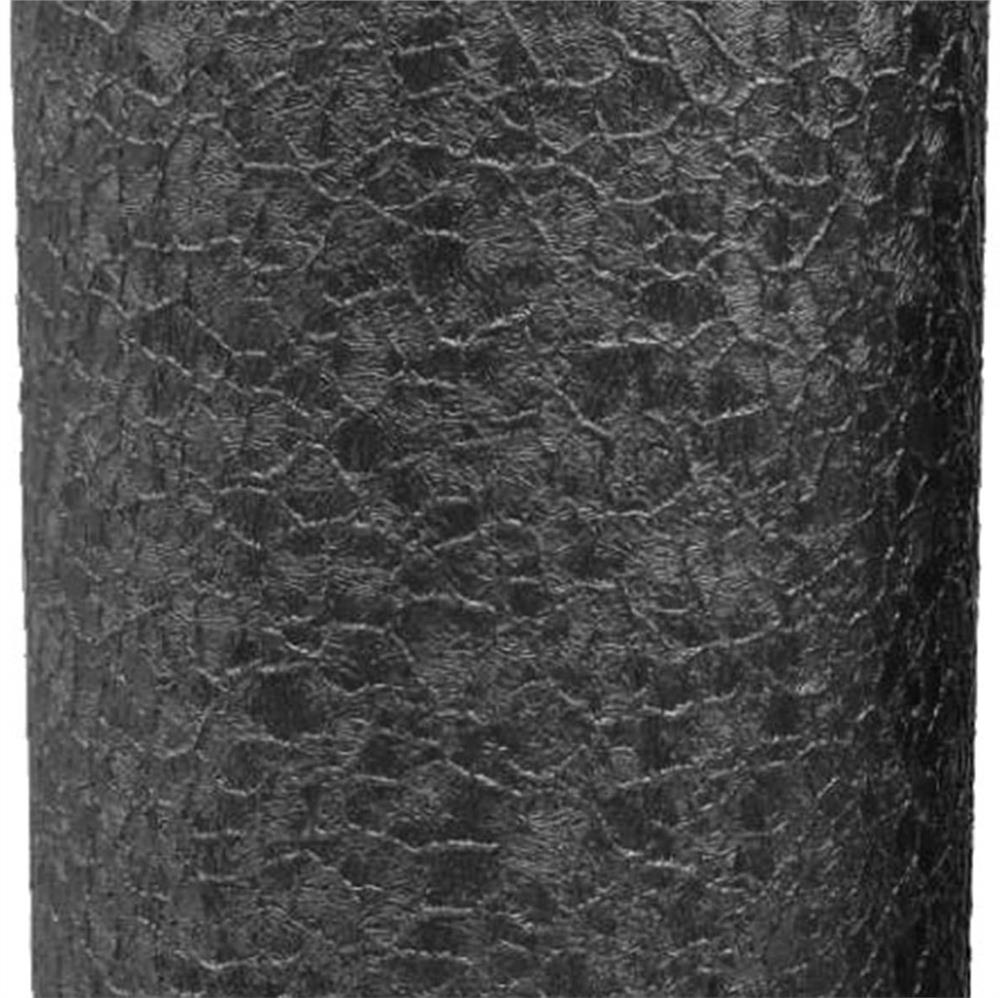

Image

Examples

Embodiment 1

[0050] A method for treating the surface of a stainless steel vacuum container with a sense of three-dimensional cloth, comprising the following steps:

[0051] a. take a stainless steel vacuum container, and carry out surface treatment to the stainless steel vacuum container;

[0052] b. Weigh the following components by weight:

[0053] 100 parts of polyester resin,

[0054] 10 parts of color pigment,

[0055] Filling 8 parts,

[0056] 2 parts crack crack additive,

[0057] Thoroughly stir and mix the above proportioned components with a disperser, then extrude into cakes and grind them into powder coatings;

[0058] c. Spray the powder coating on the surface of the stainless steel vacuum container with electrostatic powder spraying equipment. The powder spraying electrostatic voltage is 50kv, the compressed air pressure is 1.0kg, the electrostatic current is 10μa, the atomization pressure is 0.30mpa, and the powder spraying is over. Finally, a powder coating with a fil...

Embodiment 2

[0074] A method for treating the surface of a stainless steel vacuum container with a sense of three-dimensional cloth, comprising the following steps:

[0075] a. take a stainless steel vacuum container, and carry out surface treatment to the stainless steel vacuum container;

[0076] b. Weigh the following components by weight:

[0077] 100 parts of polyester resin,

[0078] 100 parts of colored pigments,

[0079] Filling 100 parts,

[0080] Crack crack additive 100 parts,

[0081] Thoroughly stir and mix the above proportioned components with a disperser, then extrude into cakes and grind them into powder coatings;

[0082] c. Spray the powder coating on the surface of the stainless steel vacuum container with electrostatic powder spraying equipment. The powder spraying electrostatic voltage is 60kv, the compressed air pressure is 2.0kg, the electrostatic current is 15μa, the atomization pressure is 0.45mpa, and the powder spraying is over. Finally, a powder coating wi...

Embodiment 3

[0098] A method for treating the surface of a stainless steel vacuum container with a sense of three-dimensional cloth, comprising the following steps:

[0099] a. take a stainless steel vacuum container, and carry out surface treatment to the stainless steel vacuum container;

[0100] b. Weigh the following components by weight:

[0101] 100 parts of polyester resin,

[0102] 55 parts of colored pigments,

[0103] Filling 54 parts,

[0104] 51 parts of tortoise crack assistant,

[0105] Thoroughly stir and mix the above proportioned components with a disperser, then extrude into cakes and grind them into powder coatings;

[0106] c. Spray the powder coating on the surface of the stainless steel vacuum container with electrostatic powder spraying equipment. The powder spraying electrostatic voltage is 55kv, the compressed air pressure is 1.5kg, the electrostatic current is 13μa, the atomization pressure is 0.35mpa, and the powder spraying is over. Finally, a powder coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com