Method for preparing barley whole powder food by extrusion and puffing combined with circulating high static pressure

A technology of extrusion puffing and high static pressure, which is applied in the processing field of barley, and can solve the problems of starch modification and no barley.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

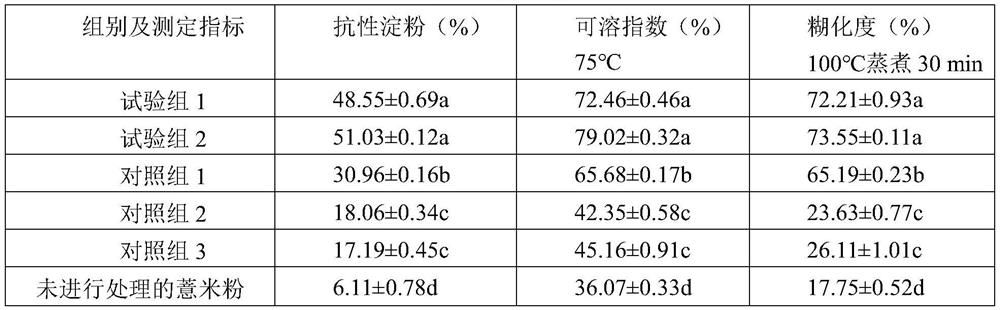

Examples

Embodiment 1

[0024] A method for preparing barley whole powder food by extrusion and expansion combined with high static pressure circulation, characterized in that it is prepared sequentially by the following steps:

[0025] (1) Pre-treatment: crush barley and pass through a 50-mesh sieve to make barley powder, mix water: barley powder at a ratio of 100:60 by mass to prepare barley powder milk solution, stir and mix well, and put it into a polypropylene bag. vacuum packaging;

[0026] (2) Cyclic high static pressure treatment: place the packaging bag in a high static pressure device at a temperature of 23°C, first at a pressure of 300MPa, hold for 3 minutes, then at a pressure of 100MPa, hold for 3 minutes, and finally return to a pressure of 300MPa, Hold pressure for 3 minutes, of which the high static pressure boost or drop rate is 8.0MPa / min;

[0027] (3) Retrograded crystallization: After the sample was subjected to high pressure treatment, the sample was retrograded to crystallize at ...

Embodiment 2

[0032] A method for preparing barley whole powder food by extrusion and expansion combined with high static pressure circulation, characterized in that it is prepared sequentially by the following steps:

[0033] (1) Pre-treatment: crush barley and pass through a 60-mesh sieve to make barley powder, mix water: barley powder at a ratio of 100:50 by mass to prepare barley powder milk solution, stir and mix well, and put it into a polypropylene bag. vacuum packaging;

[0034] (2) Cyclic high static pressure treatment: place the packaging bag in a high static pressure device at a treatment temperature of 25°C, successively at a pressure of 350MPa, hold for 4 minutes, then at a pressure of 150MPa, hold for 4 minutes, and finally return to a pressure of 350MPa, Hold pressure for 4 minutes, of which the high static pressure boost or drop rate is 8.2MPa / min;

[0035] (3) Retrograded crystallization: After the sample was treated with high pressure, it was retrograded to crystallize at...

Embodiment 3

[0040] A method for preparing barley miscellaneous grains by extrusion and expansion combined with high static pressure circulation, characterized in that it is prepared sequentially by the following steps:

[0041] (1) Pre-treatment: crush barley and pass through a 50-70 mesh sieve to make barley powder, mix water: barley powder at a ratio of 100:50 by mass to prepare a barley milk solution, stir and mix well, and put it into polypropylene In bags, vacuum packed;

[0042] (2) Cyclic high static pressure treatment: place the packaging bag in a high static pressure device at a temperature of 27°C, first at a pressure of 400MPa, hold for 5 minutes, then at a pressure of 200MPa, hold for 5 minutes, and finally return to a pressure of 400MPa, Hold pressure for 5 minutes, of which the high static pressure boost or drop rate is 8.5MPa / min;

[0043] (3) Retrograded crystals: after high-pressure treatment, retrograde crystals at 4°C for 8 hours, vacuum-dried at 60°C, and crushed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com