U-shaped hollow electric heating radiant tube

A radiant tube and electric heating technology, applied in ohmic resistance heating parts, heating element shapes, ohmic resistance electrodes, etc., can solve problems such as inability to form effective air circulation channels, slow heat dissipation, and rupture of heating radiant tubes, and reduce high temperature. Oxidation effect, prolonging service life, heating power improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

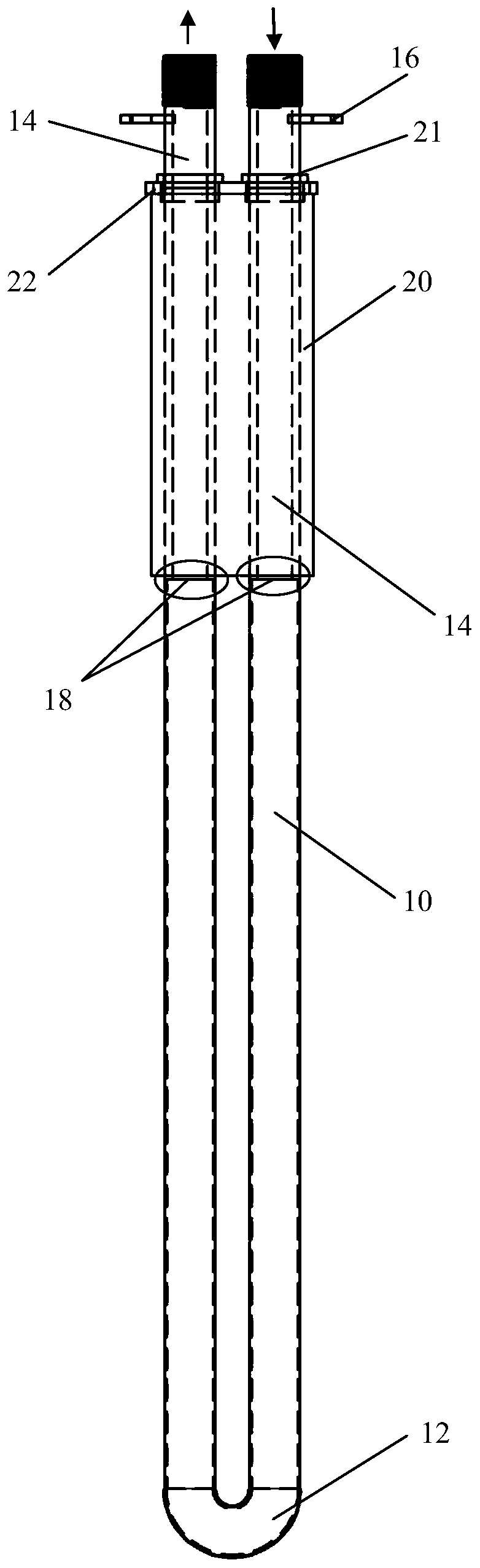

[0021] refer to figure 1 The structure diagram of the U-shaped hollow tube electric heating radiant tube of the present invention is shown. The electric heating radiant tube includes a pair of hollow heating tube bodies 10, and one end of the tube body 10 is connected and penetrated to form a U The connection part 12 of the type structure, the connection pipe 14 (electrode lead-out pipe) connected with the other end of the pipe body 10, the periphery of part of the connection pipe 14 is provided with a heat preservation section 20 composed of heat preservation material, and the connection pipe 14 is connected with the heat preservation section 20 There is a fixed plate 22 for fixing the heating radiant tube and the boiler; the end of the connecting tube 14 is provided with a threaded structure 142, which is convenient for connecting with the cooling tube; the connecting tube 14 is respectively provided with electrode connecting terminals 16 , connected to the positive and nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com