A rubber wax removal ball loaded with anti-wax agent and its preparation method, preparation device and application

A technique for preparing a device and a wax removal ball, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the wax removal ball is easy to be stuck, the wax removal ball has no wax protection, etc., and the device is simple and convenient, Wide range of applications and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]The preparation device of the rubber wax ball with wax inhibitor includes the following three parts:

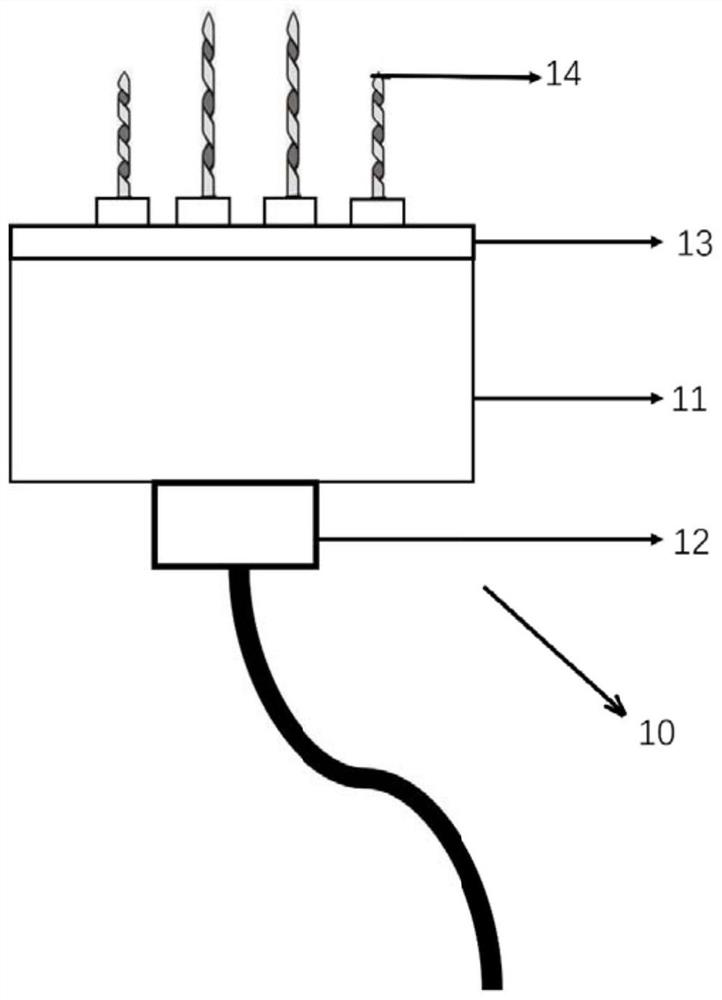

[0033]Such asfigure 1 As shown, the first part is a rubber cleaning ball perforating device 10, which includes a perforating housing 11, a motor 12, a gear linkage device, a drill bit fixing plate 13, and a plurality of drill bits 14. The gear linkage device and the drill bit fixing plate 13 are arranged in the hole Inside the housing 11. The gear linkage device includes a plurality of gears, one of which is mounted on the output shaft of the motor 12, and the other gears are mounted on one end of each drill bit 14 one by one. The other end of each drill bit 14 passes through the drill bit fixing plate 13 and then extends out to punch holes. Housing 11; each drill bit 14 is mounted on the drill bit fixing plate 13 through a bearing and a bearing seat. The motor 12 provides power to the drill bit 14 through a gear linkage device. When the motor 12 is working, the output shaft of ...

Embodiment 1

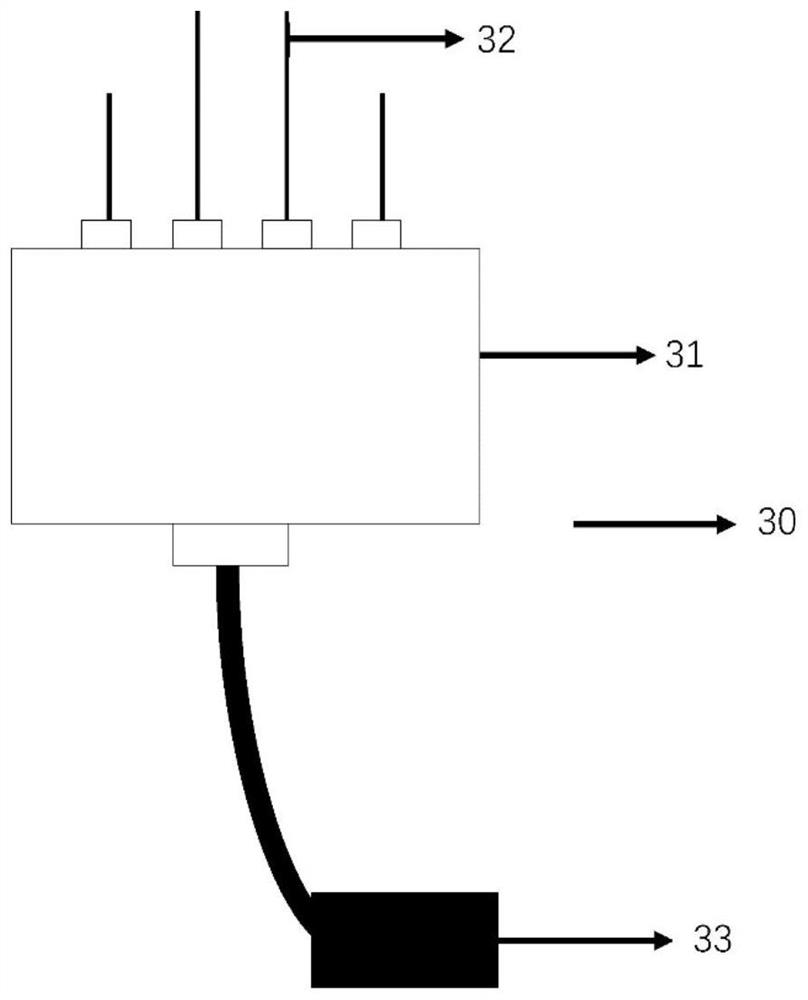

[0040]Install 4 drill bits 14 with a diameter of 2mm, a length of 2cm and 8 drills with a length of 1.7cm on the drill fixing plate 13 in a square arrangement. The spacing between the drills 14 is 3mm, and the four 2cm drills are arranged in a square in the middle. Eight 1.7cm drill bits are arranged in a square on the outside, and the motor 12 is used to drive the gear to make the drill bit 14 move, and two sets of drilling holes are drilled on the two adjacent surfaces of the rubber ball, such as the front and the left side. The injection needle 32 of the same size as the drill bit is installed on the injection housing 31 one by one according to the arrangement of the drill bit 14, and the injection housing 31 and the injection pump 33 are connected together. Dissolve 70% sodium stearate, 15% sodium citrate and 15% sodium bicarbonate with absolute ethanol as a wax inhibitor slurry.

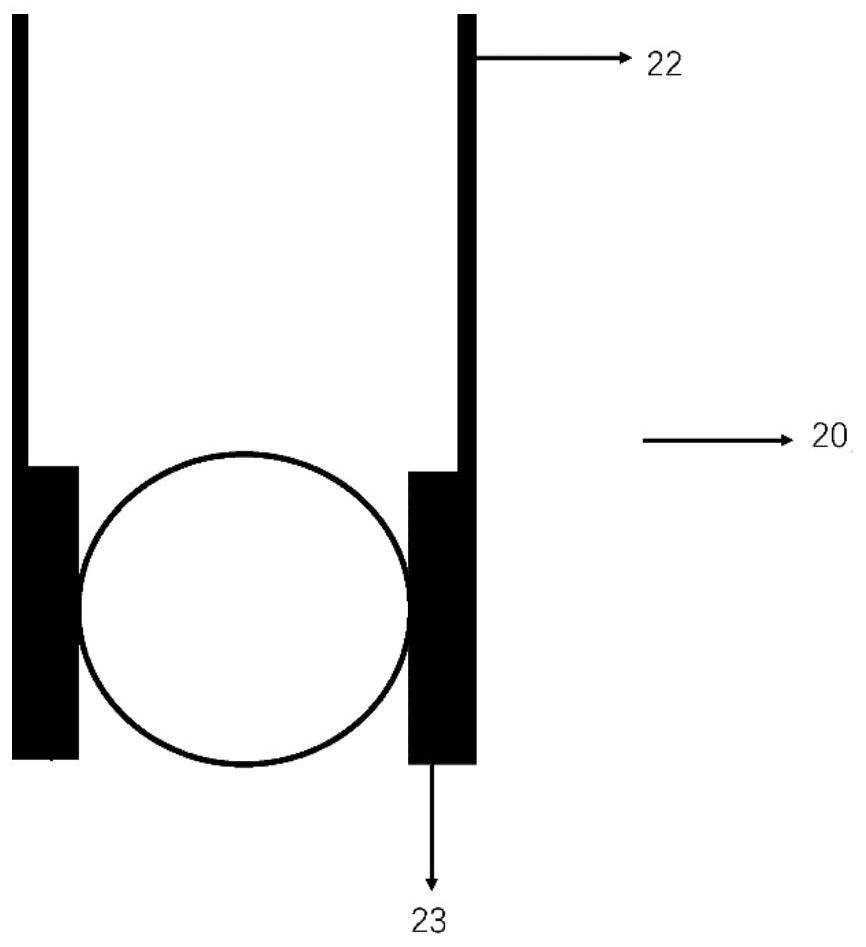

[0041]Such asFigure 4 As shown, during operation, put the ordinary rubber wax removal ball into the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com