Multifunctional numerical control machine tool

A CNC machine tool, multi-functional technology, applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc., can solve the problems of raw material compensation, inability to process, etc., to achieve reasonable structure, flexible spraying, and precision machining of workpieces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

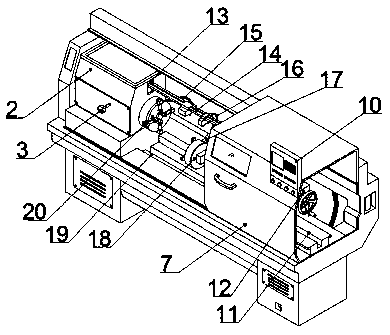

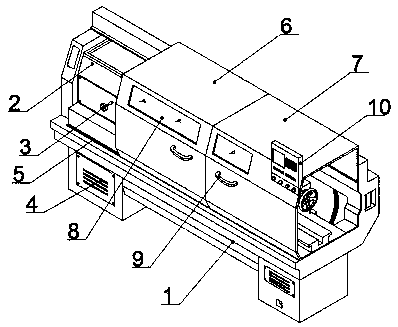

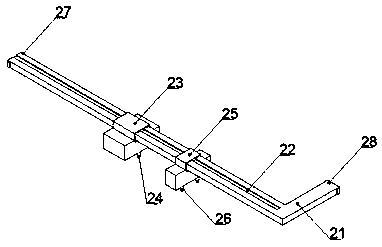

[0015] A multifunctional numerical control machine tool, comprising a machine base 1, a transmission box 2, a gear control handle 3, an inspection hatch 4, a protective door track 5, a first protective door 6, a second protective door 7, an observation window 8, and a protective door Handle 9, industrial control computer 10, tailstock guide rail 11, machine tool tailstock 12, printing rod guide rail 13, 3D printing system 14, feed pipe 15, coolant pipe 16, cutter head movable rod 17, CNC cutter head 18, iron Pin groove 19, four-jaw chuck 20, a transmission box 2 is arranged on the top left side of the machine tool base 1, a main shaft, a motor and a gearbox are arranged inside the transmission box 2, a gear position control handle 3 is arranged in front of the transmission box 2, and the inspection port There are two covers 4, which are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com