Manufacturing method of bicycle pedal crankset

A manufacturing method and bicycle technology, which is applied in the field of bicycle pedal crankset manufacturing, can solve the problems that affect the lightweight of bicycles, the inconvenience of overall assembly, and weak structural strength, so as to achieve the effects of improving industrial competitiveness, practical function characteristics, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

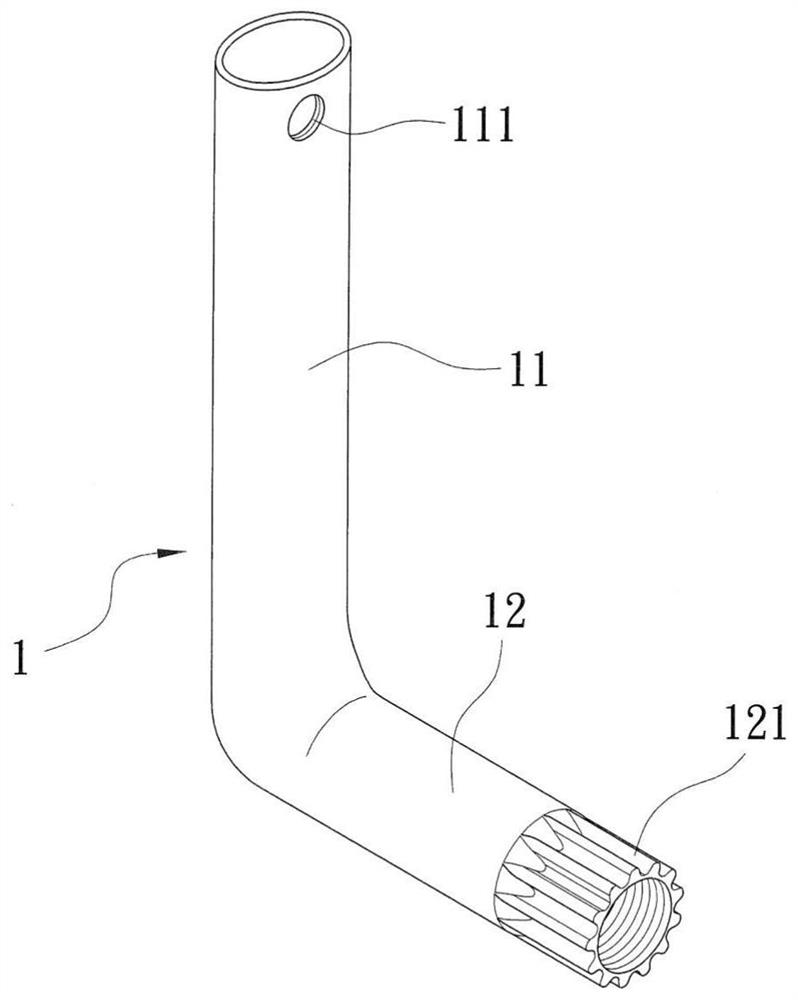

[0034] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, the following detailed description is now given, and please also refer to the disclosed drawings and figure numbers:

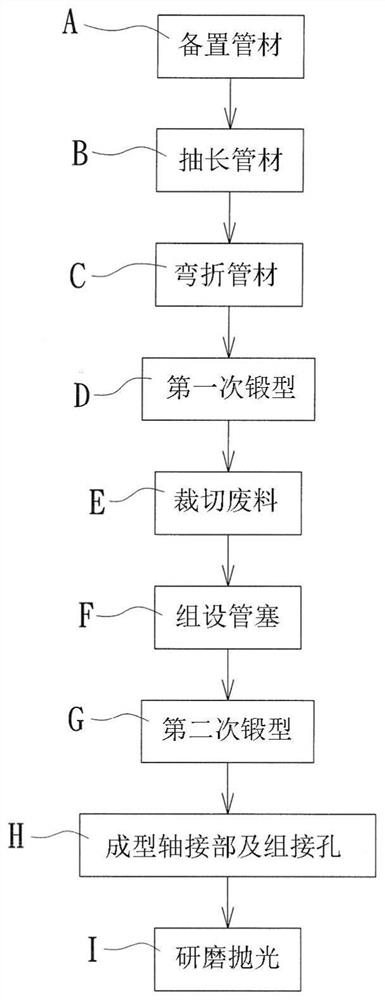

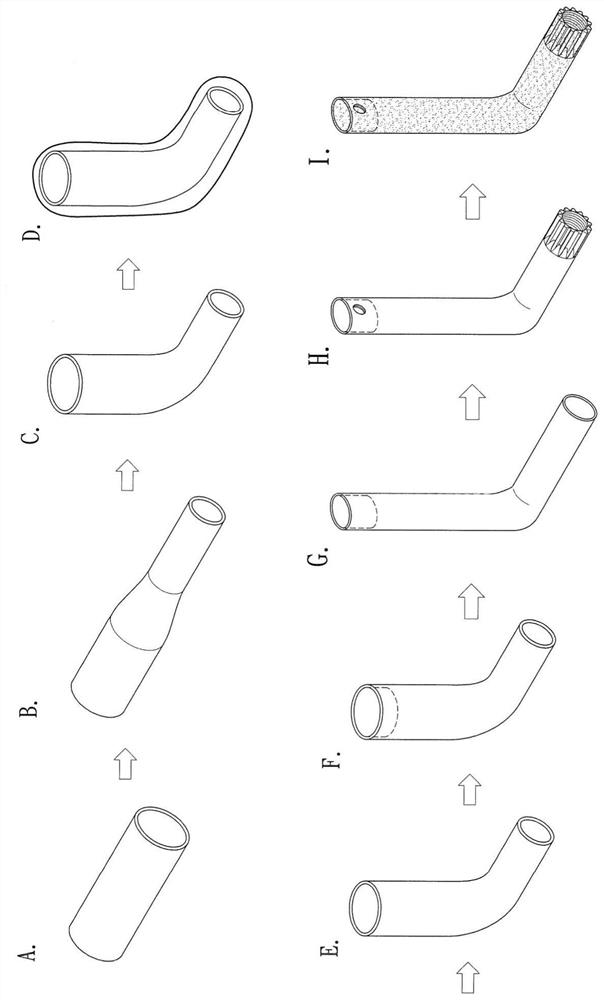

[0035] First, see figure 1 Schematic flow chart of the present invention and figure 2 Shown in the implementation status schematic diagram of the present invention, the implementation steps of the present invention include:

[0036] A. Prepare pipes: prepare aluminum alloy round pipes of appropriate length;

[0037] B. Elongate the pipe: lengthen one end of the pipe to the required length, so that one end of the pipe is elongated to form a relatively slender crankshaft section, and the other end forms a crank section;

[0038] C. Bending the pipe: bending the crankshaft section of the pipe so that the crankshaft section of the pipe and the crank section are in an L shape integrally conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com