A model-free predictive current control system and control method for boost PFC converter

A technology for predicting current and control systems, applied in electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., can solve the problems of converter parameter changes and sensitivity to internal and external disturbances, increasing the difficulty of implementation, hardware circuit complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing:

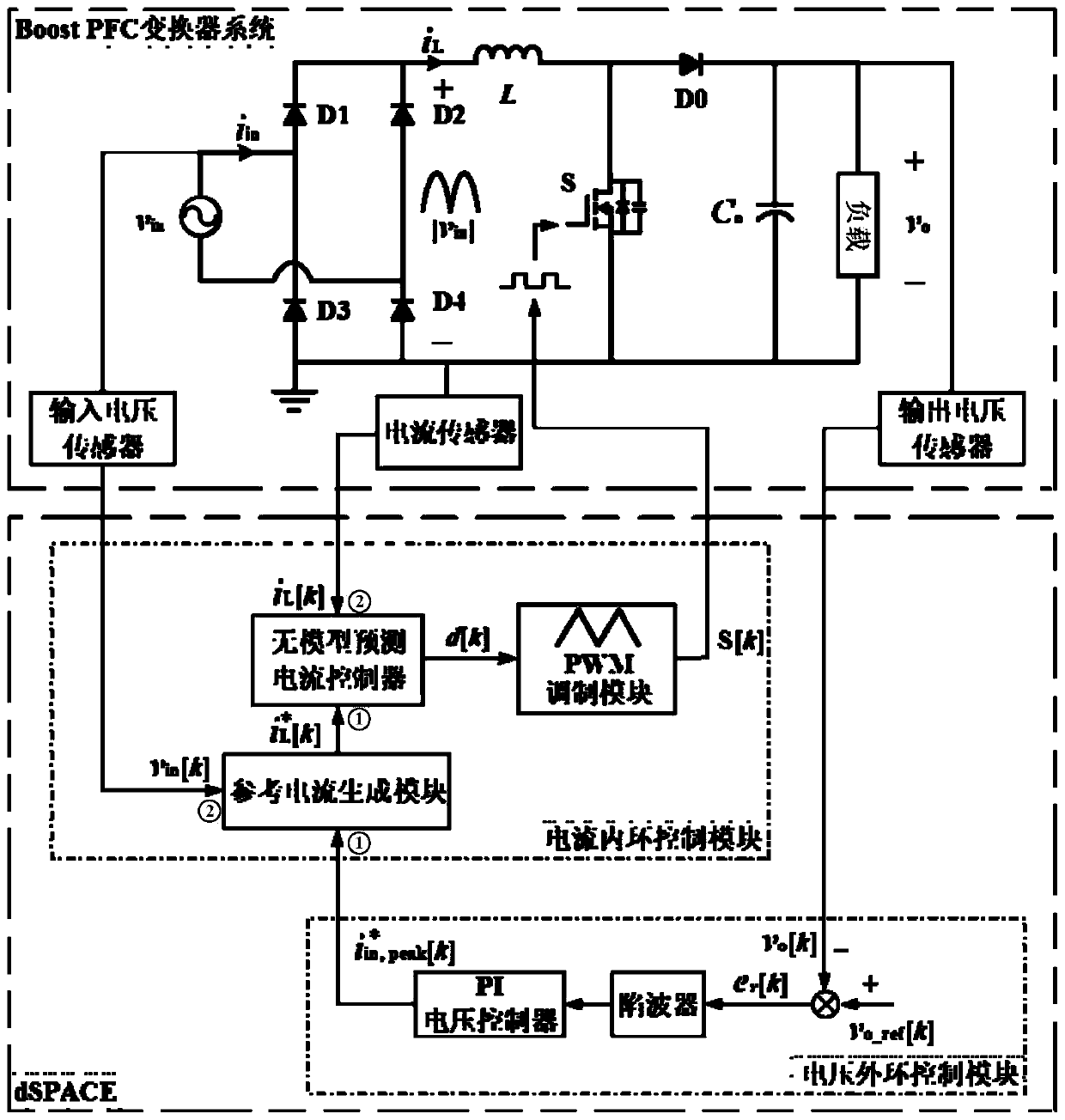

[0053] like figure 1 A model-free predictive current control system of a Boost PFC converter is shown, including a Boost PFC converter system, a current inner loop control module and a voltage outer loop control module.

[0054] Specifically, the Boost converter system includes an input power supply v in , diode rectifier bridge, boost inductor L, power switching device S, freewheeling diode D0, output capacitor C o , load, current sensor, input voltage sensor and output voltage sensor; the diode rectifier bridge includes diode D1, diode D2, diode D3 and diode D4; the input power supply v in One end of the diode D1 is connected to the anode of the diode D1, and the other end is connected to the anode of the diode D2; the cathodes of the diode D1 and the diode D2 are both connected to the anode of the freewheeling diode D0 through the boost inductor L; the anode of the dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com