Swirl blade, swirl fan, swirl pipeline and preparing method of swirl pipeline

A technology of swirling blades and fans, which is applied in heat exchange equipment, lighting and heating equipment, heat transfer modification, etc., and can solve the problems that the effect of tube heat exchange needs to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

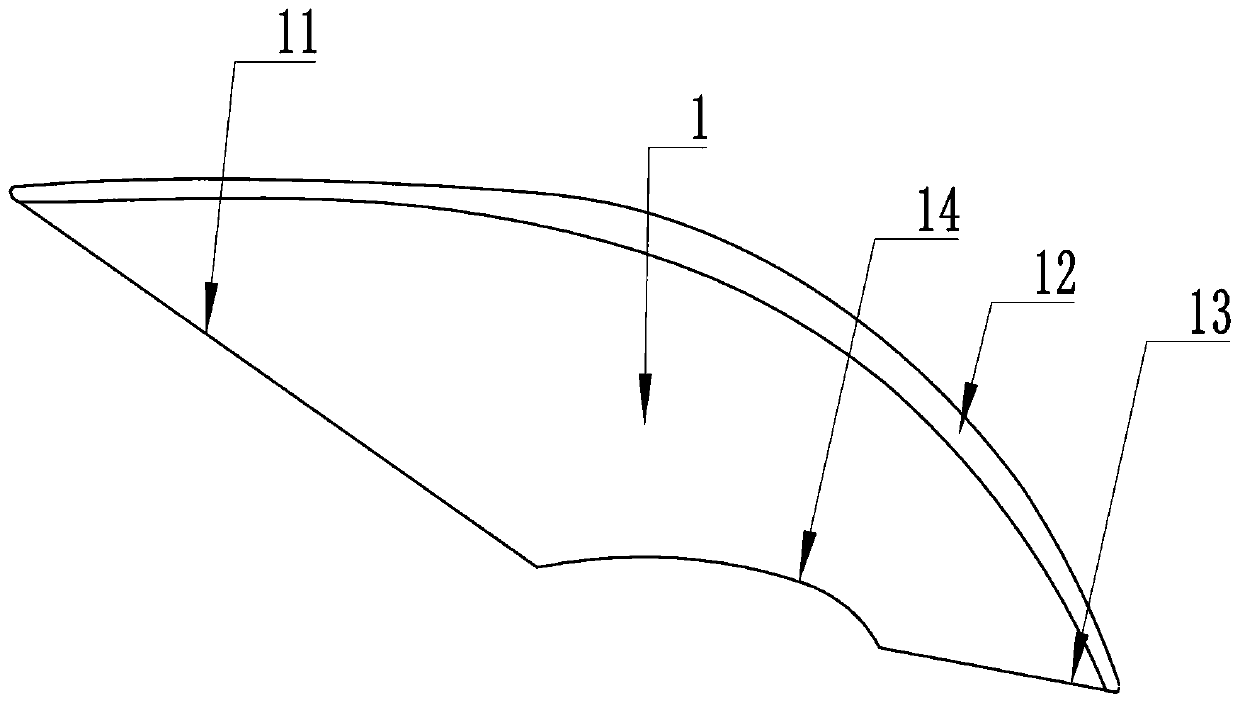

[0040] The first embodiment provides a swirl blade 1, please refer to figure 1 , the swirl blade 1 includes a leading edge 11 , a back arc 12 , a trailing edge 13 and an inner arc 14 which are connected end to end in sequence. The leading edge 11 faces the air intake direction of the swirl fan, and the trailing edge 13 faces the air outlet direction of the swirl fan.

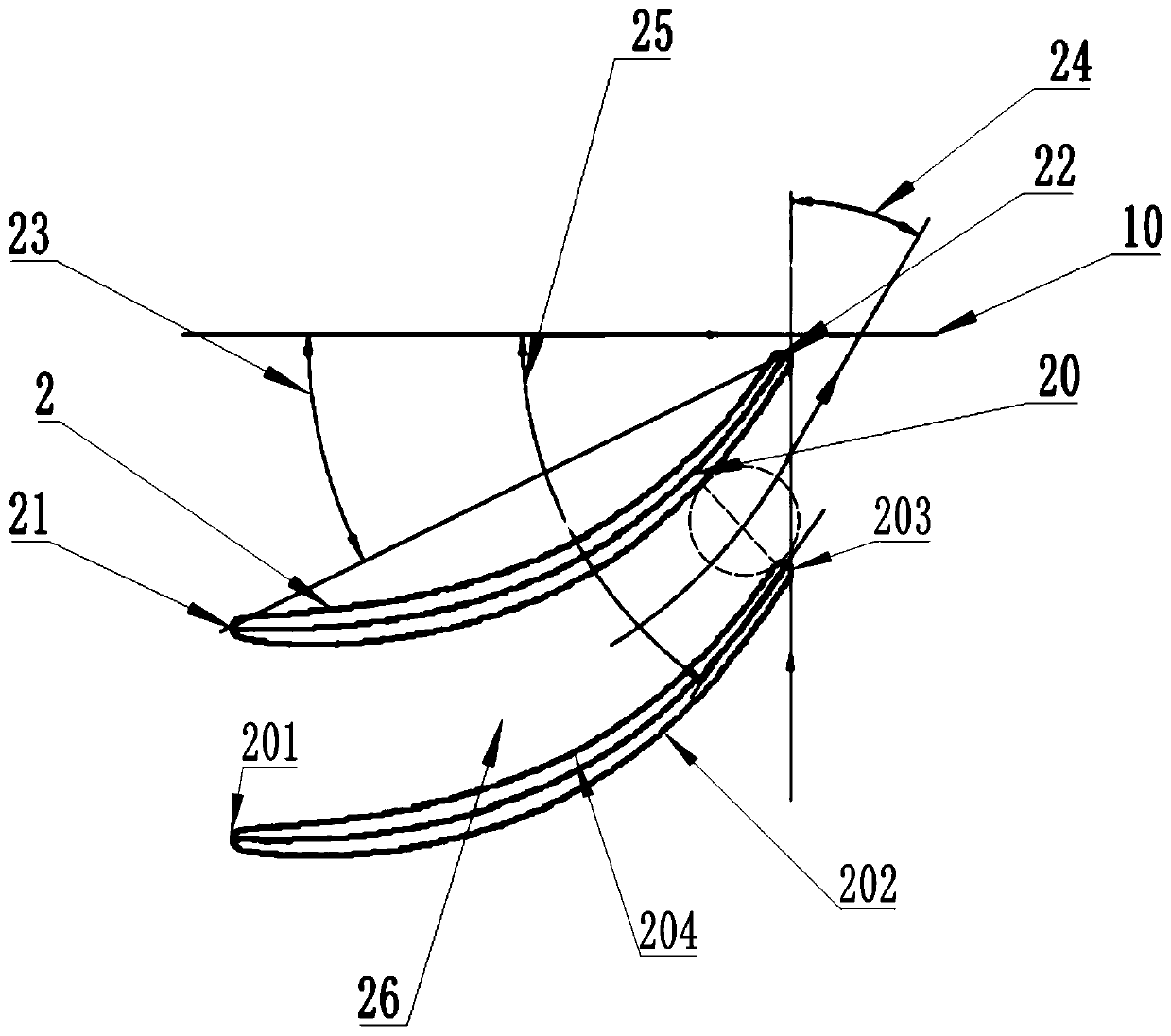

[0041] Please refer to figure 2 , the swirl vane 1 rotates around the rotation axis 10 . The projection of the swirl blade 1 on the cylindrical surface coaxial with the rotation axis 10 forms the blade profile line 2, and the blade profile line 2 is a closed curve, including a leading edge line 201, a back arc line 202, and a trailing edge line that are connected end to end in sequence 203 and inner arc 204. The intersection of the mid-arc line of the blade profile 2 and the leading edge line 201 is the leading edge point 21 , and the intersection of the mid-arc line of the blade profile 2 and the trailing e...

Embodiment 2

[0046] This embodiment provides a swirl fan, including a plurality of swirl blades 1 in the first embodiment.

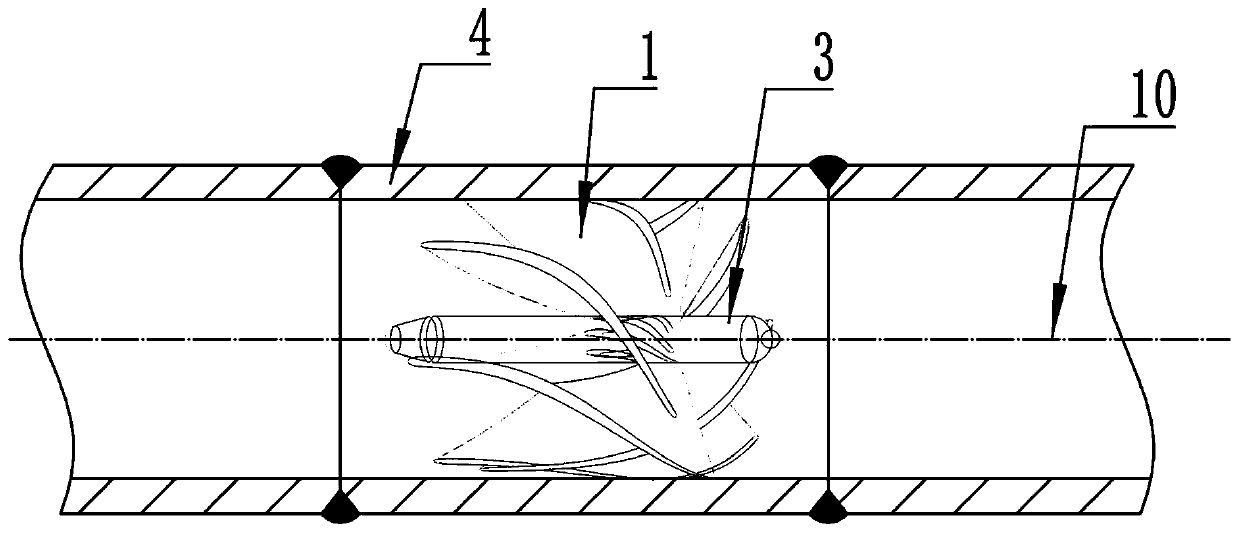

[0047] Please refer to image 3 , the swirl fan also includes a hub 3 . The plurality of swirl blades 1 are mounted on the hub 3 and are evenly distributed around the axis of the hub 3 . The axis of the hub 3 is the rotation axis 10 , and the inner arc 14 of the swirl blade 1 is fixedly connected to the hub 3 . Specifically, the hub 3 initially has an inner arc 14-shaped hole matching the shape of the inner arc 14 , and the inner arc 14 is inserted into the inner arc 14-shaped hole and fixedly connected to the hub 3 .

[0048] Please refer to figure 2 , the two adjacent swirl vanes 1 are the first swirl vane and the second swirl vane respectively, and the projections of the first swirl vane and the second swirl vane on the same cylindrical surface are respectively the first swirl vane type Wire( figure 2 The swirl vane profile above the swirl vane) and the sec...

Embodiment 3

[0056] This embodiment provides a swirl pipeline 4 and a preparation method thereof. The swirl fan provided in the second embodiment is installed in the swirl duct 4 .

[0057] Please refer to image 3 , a plurality of back arc 12-shaped line holes matching the shape of the back arc 12 of the swirl vane 1 are opened on the pipe wall of the swirl duct 4, and the back arc 12 of each swirl vane 1 is inserted into a corresponding back arc. 12-type wire hole, fixedly connected to the swirl pipe 4.

[0058] The preparation method of the swirl pipe 4 comprises the following steps:

[0059] prepare a plurality of swirl blades 1;

[0060] The swirl pipe 4 is divided into two parts along the axis;

[0061] A plurality of inner arc 14-shaped line holes are set on the hub 3, the inner arc 14 of each swirl blade 1 is inserted into the corresponding inner arc 14-shaped line hole, and the swirl blade 1 and the hub 3 are welded;

[0062] A plurality of back-arc 12-shaped line holes are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com