Method for recovering copper and tin in waste tin-plated and copper-coated plates

A copper-clad laminate and tin-plating technology, which is applied in the field of recycling copper and tin in waste tin-plated copper-clad laminates, can solve a large amount of waste water and other problems, achieve high recovery rate, simple process flow, and facilitate industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

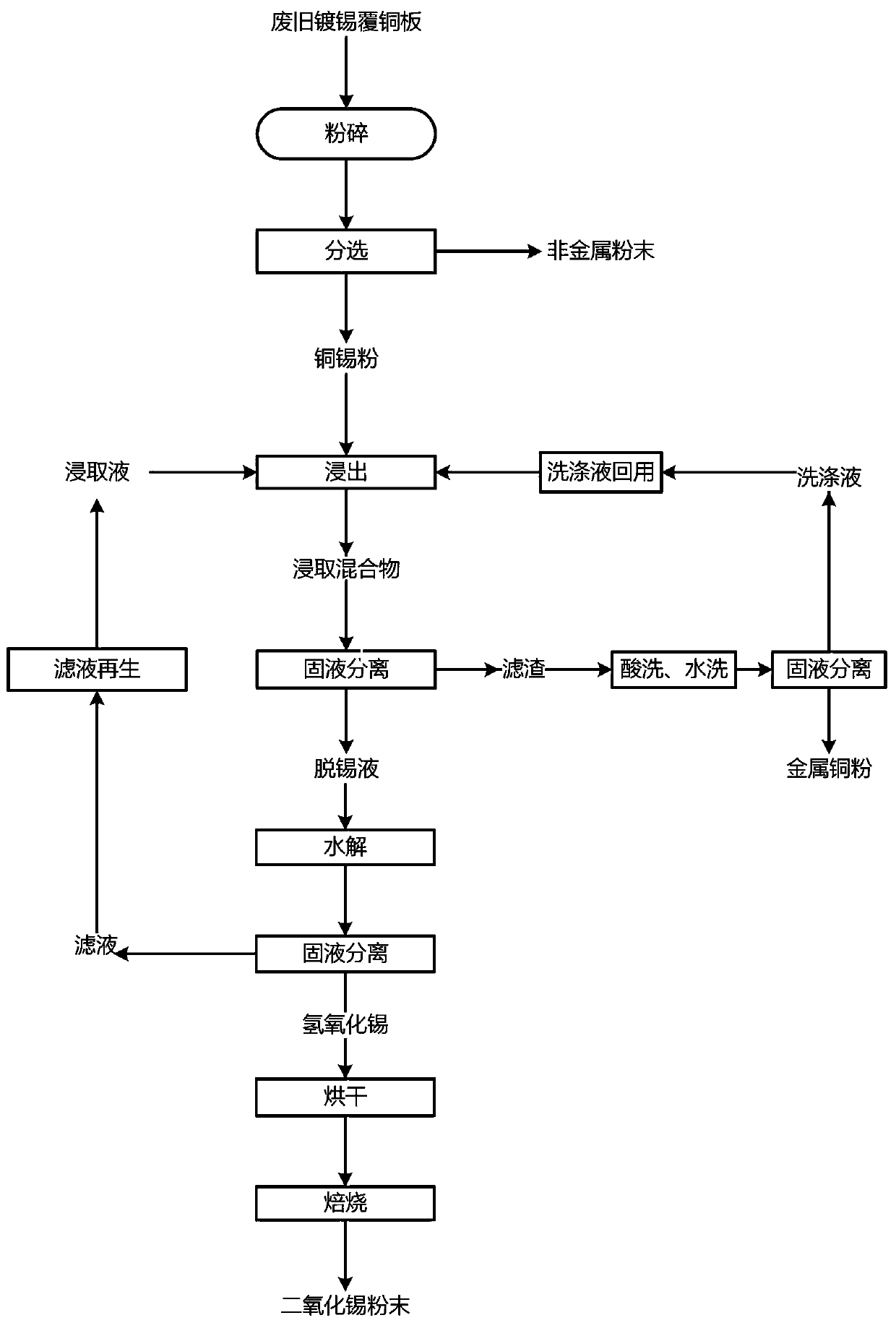

[0040] One of the method implementations of copper and tin in a kind of recycling waste tin-plated copper-clad laminate of the present invention, such as figure 1 Show, the content of metal tin in the copper-tin powder in the present embodiment is 5.44%, and the content of copper is 90.21%, and resin powder slag and other metal content are 4.35%.

[0041] A method for reclaiming copper and tin in waste tinned copper-clad laminates of the present invention, its technological process is as follows figure 1 shown, including the following steps:

[0042] (1) Carry out mechanical primary crushing and crushing of waste tinned copper-clad laminates to obtain copper-clad laminate powder;

[0043] (2) Sorting the copper-clad laminate powder through a hydraulic shaker to obtain copper-tin powder and non-metallic powder;

[0044] (3) Mix the copper tin powder and the leaching solution in two batches with a solid-to-liquid ratio of 1:4 and add them to a three-necked flask for leaching. ...

Embodiment 2

[0051] One of the embodiments of the method for recycling copper and tin in waste tin-plated copper-clad laminates of the present invention, the main technical solution of this embodiment 2 is basically the same as that of embodiment 1, and the features not explained in this embodiment 2, The explanation in Embodiment 1 is adopted, and details are not repeated here. The difference between this example and Example 1 is that in step (3), the copper-tin powder and the leaching solution are mixed into a three-necked flask with a solid-to-liquid ratio of 1:5, and the initial feeding is 60%, and the second feeding is 40%. Raise the temperature to 70°C for leaching reaction for 20 minutes, wherein the concentration of sulfuric acid is 80ml / L, CuCl 2 The concentration is 30g / L.

[0052] After testing, the metal copper content is 99.83%, the metal tin content is 0.17%, and the tin oxide purity is 99.25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com