High-pressure vacuum vibration shaping machine

A vibration molding machine and vacuum technology, which is applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of automatic material distribution and insufficient pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

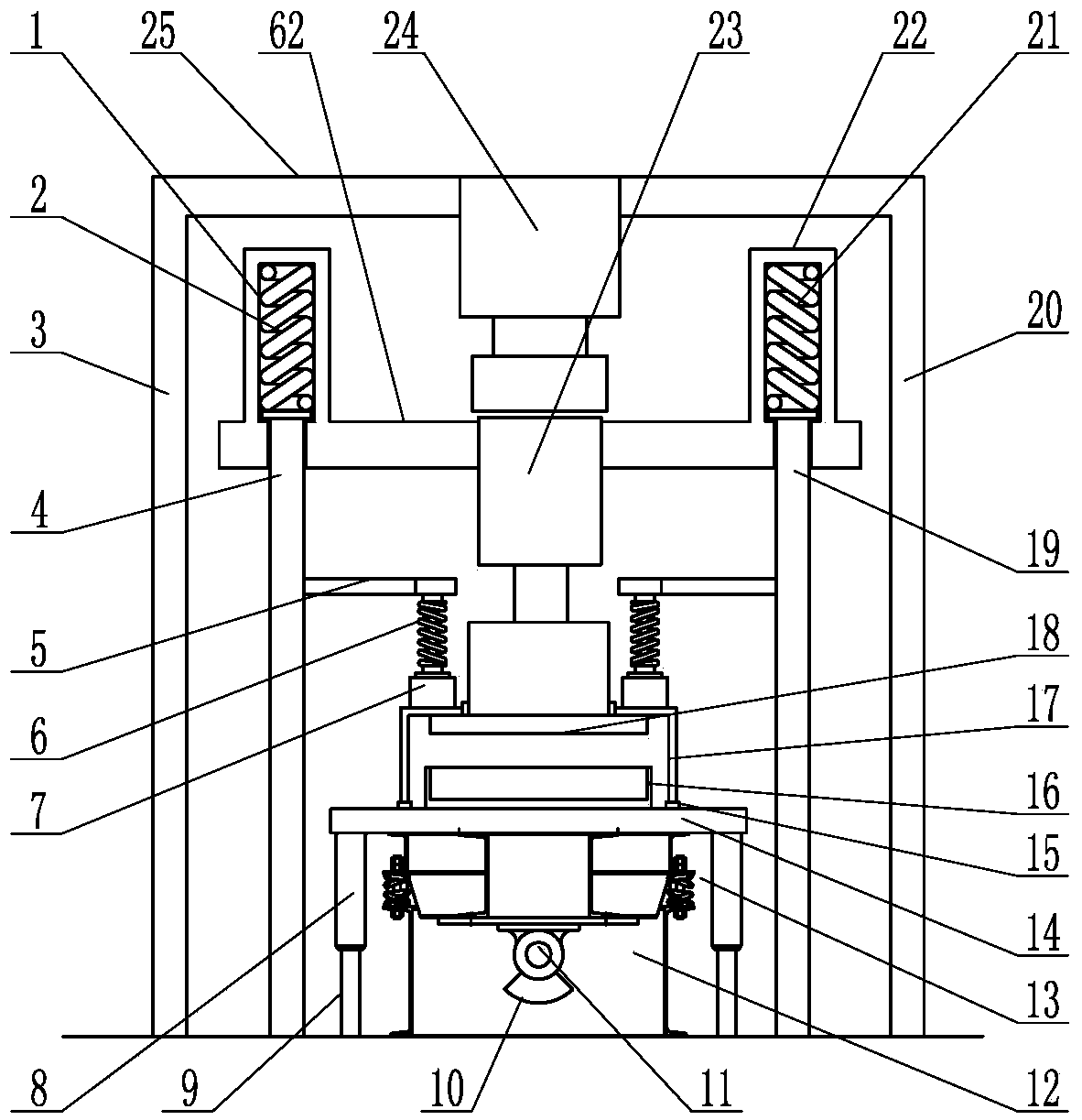

[0046] Such as figure 1 As shown, the high-pressure vacuum vibration molding machine of the present invention includes an outer frame, an inner frame, a base, a vibrator, a vibrating table, a die, a briquetting block, a first press, a second press and a vacuum chamber , the base, vibrator, vibrating table, die, briquette and vacuum chamber are all arranged in the inner frame; the vibrator is connected to the vibrating table, and the vibrating table is installed on the base through a spring device; Die, die cavity is opened on the die, the briquetting block is located above the die, and the briquetting block is connected to the telescopic arm of the first press, and the first press is installed on the top of the inner frame; the second press is installed on the outer On the frame and above the first press; the vibrator includes a vibrating motor installed on the bottom of the vibrating table, and an eccentric runner is installed on the motor shaft of the vibrating motor.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com