Preparation method for phase-change heat storage capsule used for thermal adjusting of power lithium battery

A phase change heat storage and lithium battery technology, which is applied in microcapsule preparations, microsphere preparation, heat exchange materials, etc., can solve the problems of liquid molten salt being easily lost, leaking, corrosive, unsuitable for phase change energy storage materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

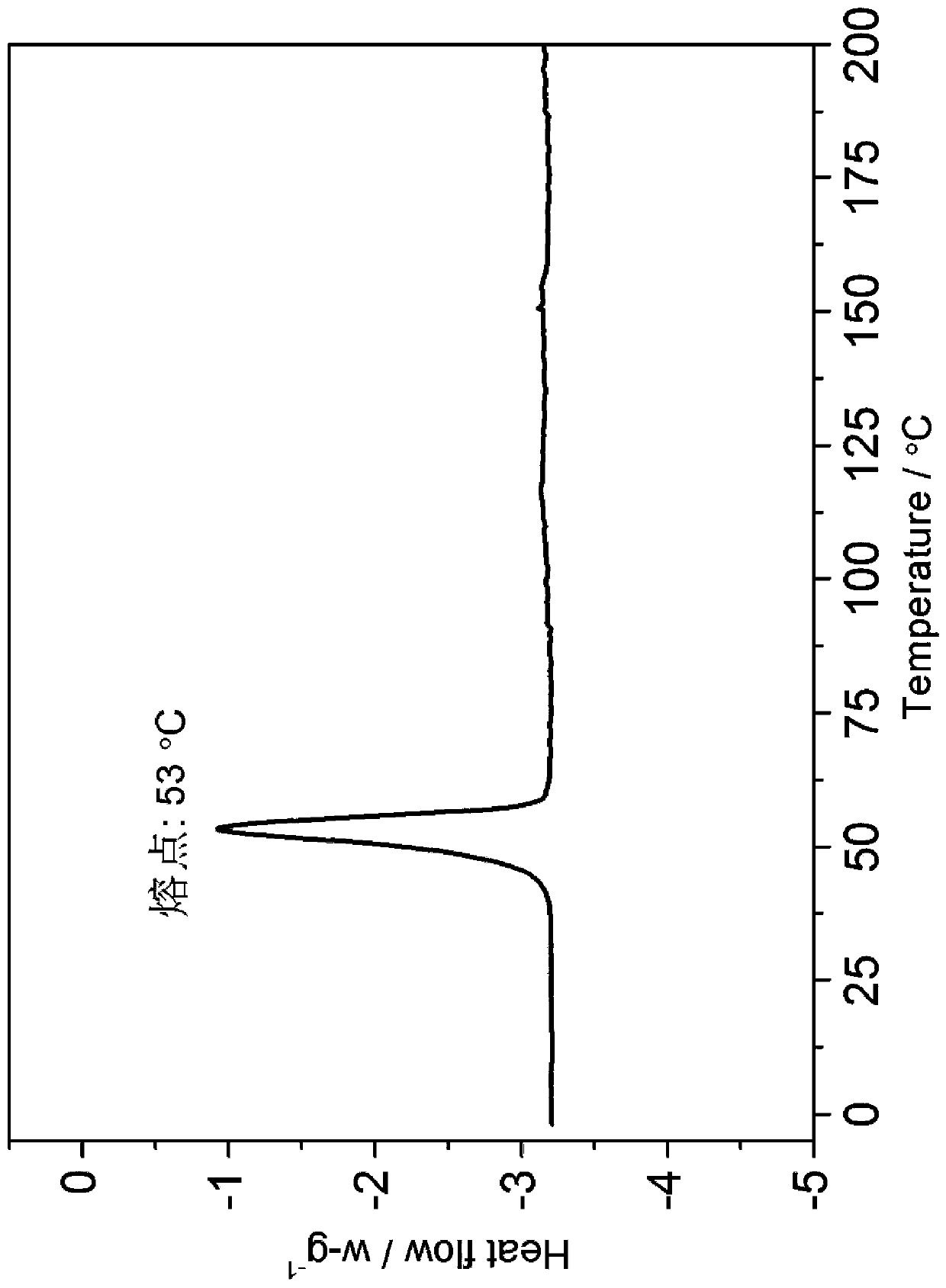

[0016] 20~35wt% lithium nitrate, 1.5~5wt% sodium nitrate, 2.5~10wt% potassium nitrate, 2~10wt% calcium nitrate, 5~15wt% sodium nitrite, 15~35wt% sodium chloride, 1~6wt% carbonic acid Potassium and 1-8wt% potassium sulfate are mixed and ground into fine powder, dried at 150°C for 10 hours, mixed according to a certain mass fraction ratio to obtain a mixed salt (melting point is 50-55°C), heated and melted at 200°C for 10 hours, Take it out and put it in a desiccator to cool, then grind it into a fine powder, and sieve it with a 120-mesh sieve;

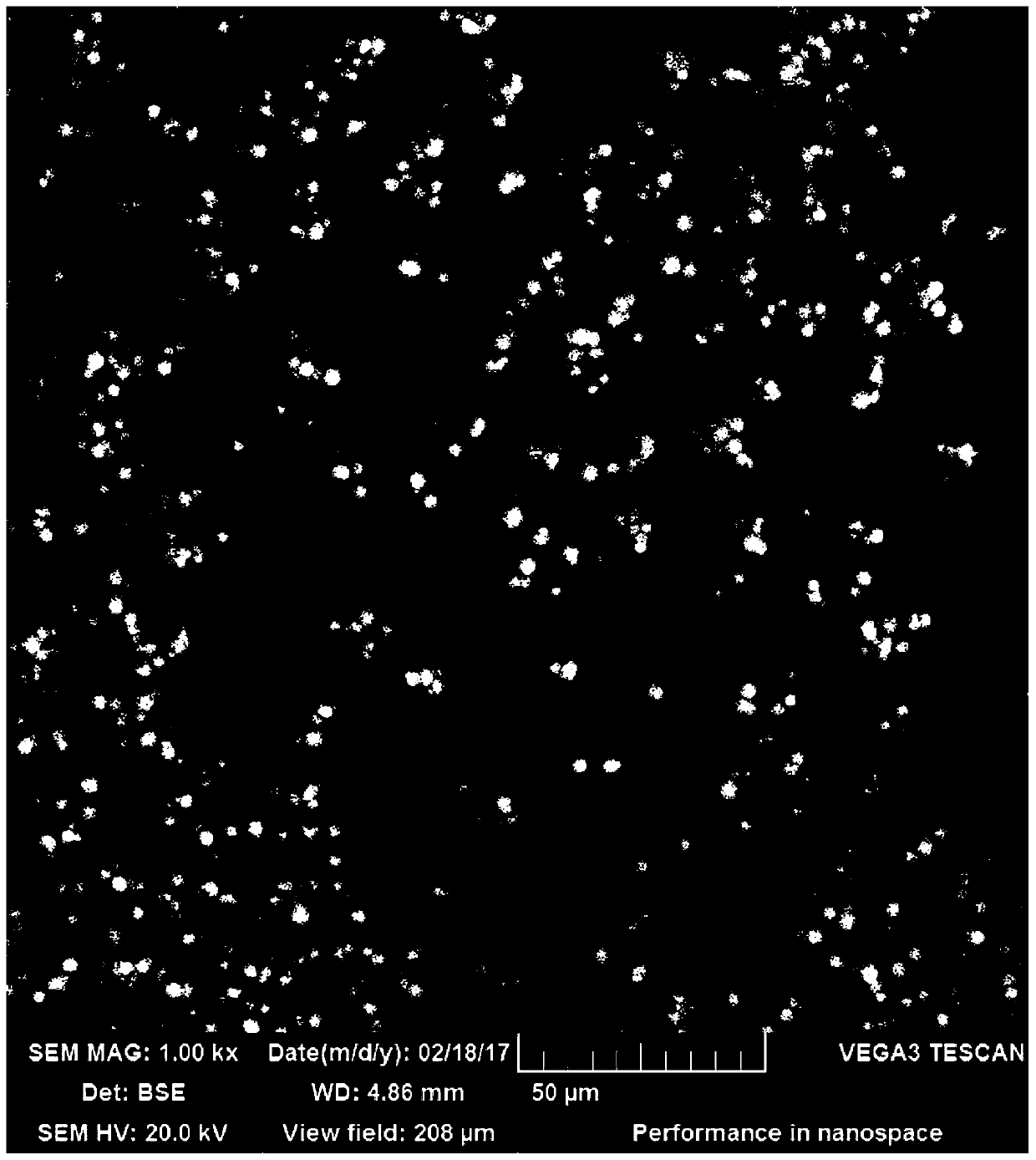

[0017] Put 4 grams of sieved mixed molten salt fine powder and 15 milliliters of n-butyl ether in a round-bottomed flask, and after 30 minutes of ultrasonic dispersion, add 3 grams of n-butyl ether of perhydropolysilazane (PHPS) Solution (mass fraction is 30%), adopt magnetic stirring to mix evenly, then add 150 grams of n-dodecane and stir and extract for 15 minutes, let stand for 30 minutes, remove the mixed solution of n-butyl ether ...

Embodiment 2

[0019] 20~35wt% anhydrous lithium nitrate, 1.5~5wt% sodium nitrate, 2.5~10wt% potassium nitrate, 2~10wt% anhydrous calcium nitrate, 5~15wt% sodium nitrite, 15~35wt% sodium chloride, 1 ~6wt% potassium carbonate and 1~8wt% potassium sulfate are mixed and ground into fine powder, dried at 150°C for 10 hours, mixed according to a certain mass fraction ratio to obtain mixed salt (melting point is 50~55°C), heated at 200°C Melt for 10 hours, take it out and put it in a desiccator to cool, then grind it into a fine powder, and sieve it with a 120-mesh sieve;

[0020] Put 4 grams of sieved mixed molten salt fine powder and 15 milliliters of n-butyl ether in a round-bottomed flask, and after 30 minutes of ultrasonic dispersion, add 3 grams of n-butyl ether of perhydropolysilazane (PHPS) Solution (mass fraction is 30%), adopt magnetic stirring to mix evenly, then add 150 grams of n-dodecane and stir and extract for 15 minutes, let stand for 30 minutes, remove the mixed solution of n-but...

Embodiment 3

[0022] 35~63wt% lithium nitrate trihydrate, 1.5~5wt% sodium nitrate, 2.5~10wt% potassium nitrate, 2.5~15wt% calcium nitrate tetrahydrate, 5~15wt% sodium nitrite, 15~35wt% sodium chloride, 1 ~6wt% potassium carbonate and 1~8wt% potassium sulfate are mixed and ground into fine powder, dried at 150°C for 10 hours, mixed according to a certain mass fraction ratio to obtain mixed salt (melting point is 50~55°C), heated at 200°C Melt for 10 hours, take it out and put it in a desiccator to cool, then grind it into a fine powder, and sieve it with a 120-mesh sieve;

[0023] Put 4 grams of sieved mixed molten salt fine powder and 15 milliliters of n-butyl ether in a round-bottomed flask, and after 30 minutes of ultrasonic dispersion, add 3 grams of n-butyl ether of perhydropolysilazane (PHPS) Solution (mass fraction is 30%), adopt magnetic stirring to mix evenly, then add 150 grams of n-dodecane and stir and extract for 15 minutes, let stand for 30 minutes, remove the mixed solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com