Black-skin chicken abietic fungus spicy sauce

A technology of chicken fir mushroom and spicy sauce, which is applied in the field of food seasoning, can solve the problems of complex production, etc., and achieve the effect of simple operation, mellow sauce, and suitable spicy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

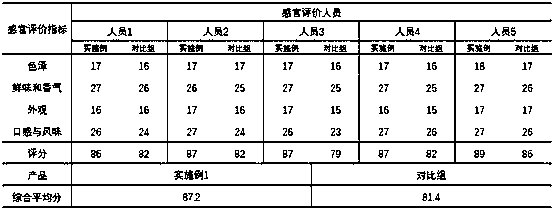

Embodiment 1

[0034]A black-skinned chicken fir mushroom spicy sauce is composed of the following raw materials in parts by weight: 45 parts of fried chicken fir mushroom, 35 parts of chicken fir mushroom oil, 1.2 parts of minced ginger, 0.5 part of minced garlic, 3 parts of chili powder, and 0.1 part of prickly ash powder , 0.5 parts of sweet noodle sauce, 0.2 parts of spices, 2 parts of oyster sauce, 2 parts of peanuts, 2 parts of sugar, and 0.2 parts of table salt. and prepared by the following method steps:

[0035] (1) Raw material pretreatment:

[0036] Fresh chicken fir fungus: select the fresh chicken fir fungus with intact cells, remove impurities, and no pollution, wash them, cut and separate the stipe and cap with a knife, and cut the stipe into 10mm small pieces; add it to the boiling water pot Blanch in medium for 30s, then remove, drain and set aside.

[0037] Peanuts: add a small amount of oil to a hot pan, and stir-fry the required peanuts at 40°C for 15 minutes to remove ...

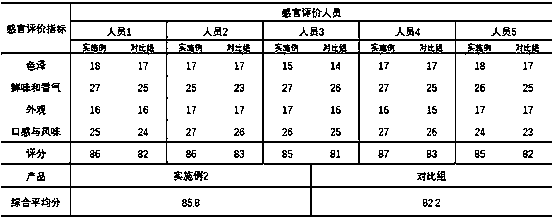

Embodiment 2

[0050] A kind of black-skinned chicken fir mushroom spicy sauce is made up of the following raw materials in parts by weight: 55 parts of fried chicken fir mushroom, 45 parts of chicken fir mushroom oil, 1.6 parts of minced ginger, 1.2 parts of minced garlic, 6 parts of chili powder, and 0.5 part of prickly ash powder , 1.4 parts of sweet noodle sauce, 0.8 parts of spices, 5 parts of oyster sauce, 10 parts of peanuts, 5 parts of sugar, and 0.5 parts of table salt. and prepared by the following method steps:

[0051] (1) Raw material pretreatment:

[0052] Fresh chicken fir fungus: select the fresh chicken fir mushroom with intact cells, remove impurities, and no pollution, wash it, cut the stipe and cap with a knife, cut the stipe into 20mm small pieces; add it to the boiling water pot Blanch in medium for 60s, then remove, drain and set aside.

[0053] Peanuts: add a small amount of oil to a hot pan, and stir-fry the required peanuts at 70°C for 20 minutes to remove moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com