Bus bar, solar cell module and manufacturing method of solar cell module

A solar cell and bus bar technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high manufacturing cost, low production efficiency, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

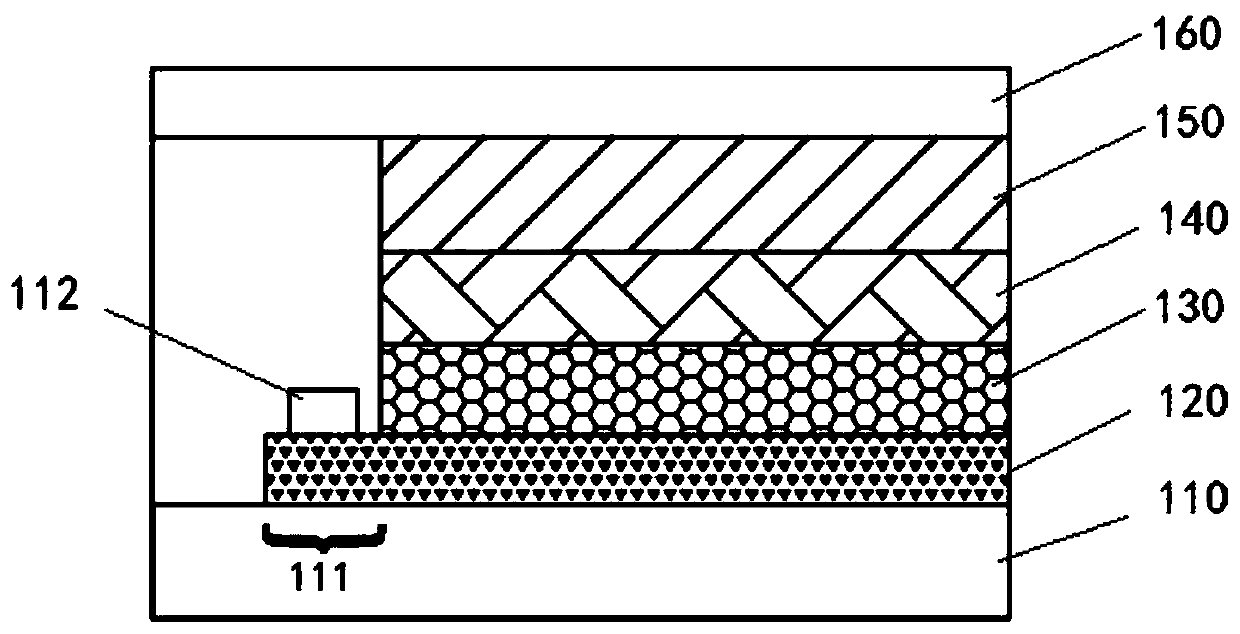

[0028] Thin-film solar cell modules are usually thin-film solar cell modules in which a metal back electrode layer, a p-type light absorption layer, a high-resistance buffer layer, an n-type window layer (transparent conductive film) are laminated on the surface of a substrate. A bus bar is welded on the current lead-out part of the back electrode layer, and then a sealing effect is used such as ethylene-vinyl acetate copolymer resin (Ethylene-Vinyl Acetate, EVA), polyvinyl butyral resin (PolyVinyl Butyral, PVB), etc. The filling material is sealed with the front sealing glass.

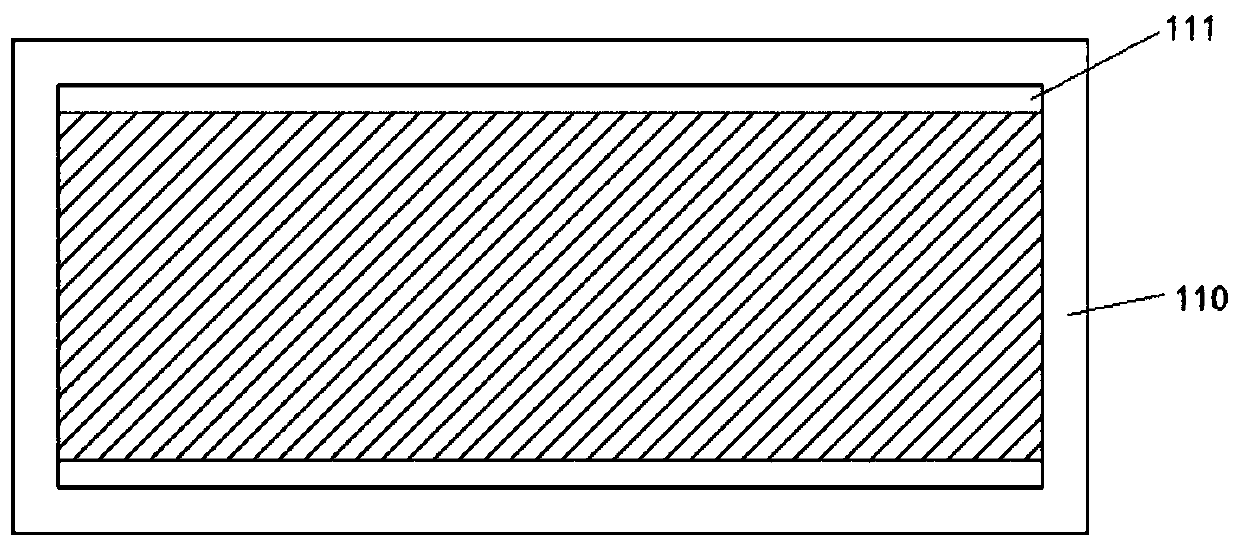

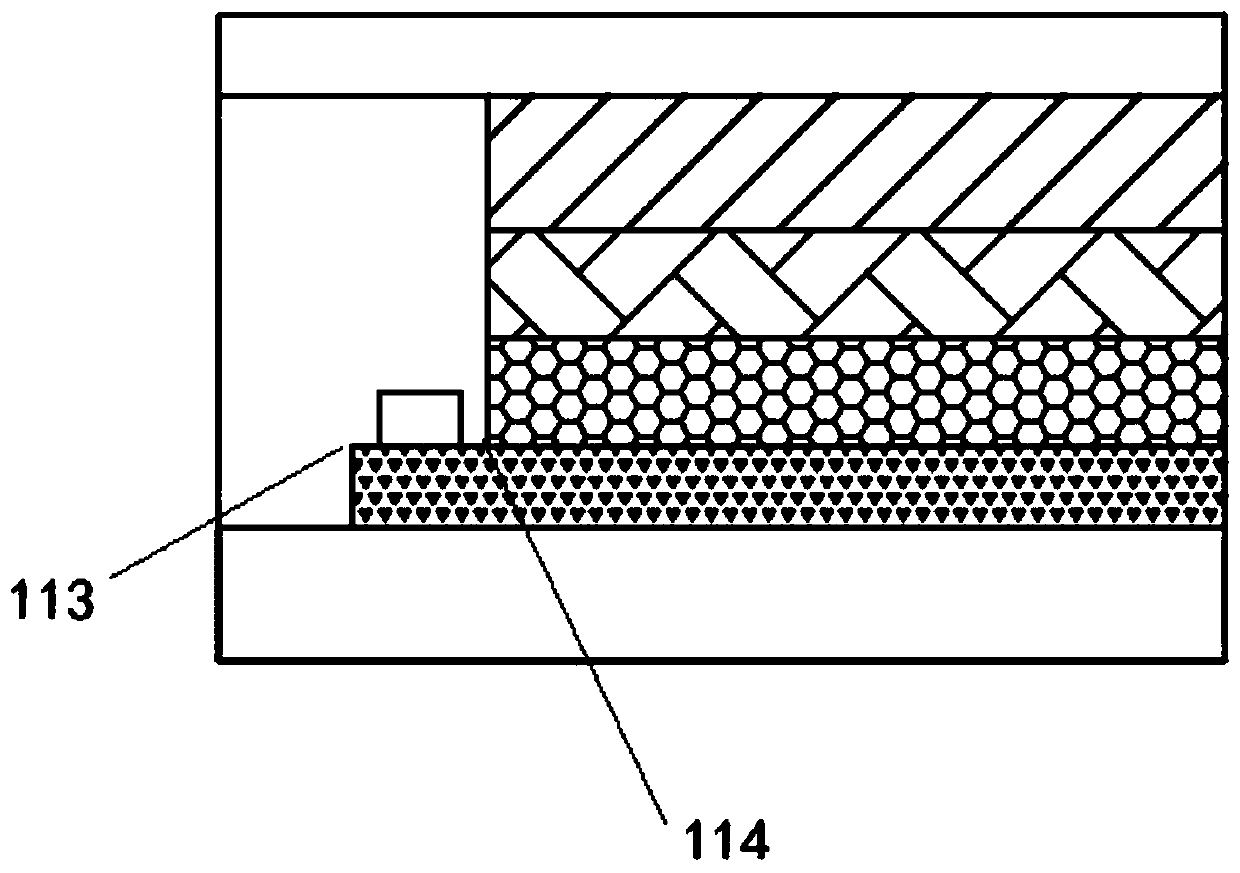

[0029] Such as figure 1 As shown, the solar cell module of the present invention at least includes: a substrate 110; a first electrode layer 120 formed above the substrate 110, a second layer (130, 140, 150) formed above the first electrode layer 120, The solar cell module further includes a bus bar connection area where the second layer is not formed on the first electrode layer, and a bus bar is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com