A bearing defect automatic detection system based on multi-angle light source images

A defect detection and automatic detection technology, which is applied in the direction of optical defect/defect, image analysis, image enhancement, etc., can solve the problems that bearing identification characters cannot be intelligently recognized, defects are difficult to identify and detect, and errors are easy to generate, so as to achieve fine small errors , intelligent detection, fast and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

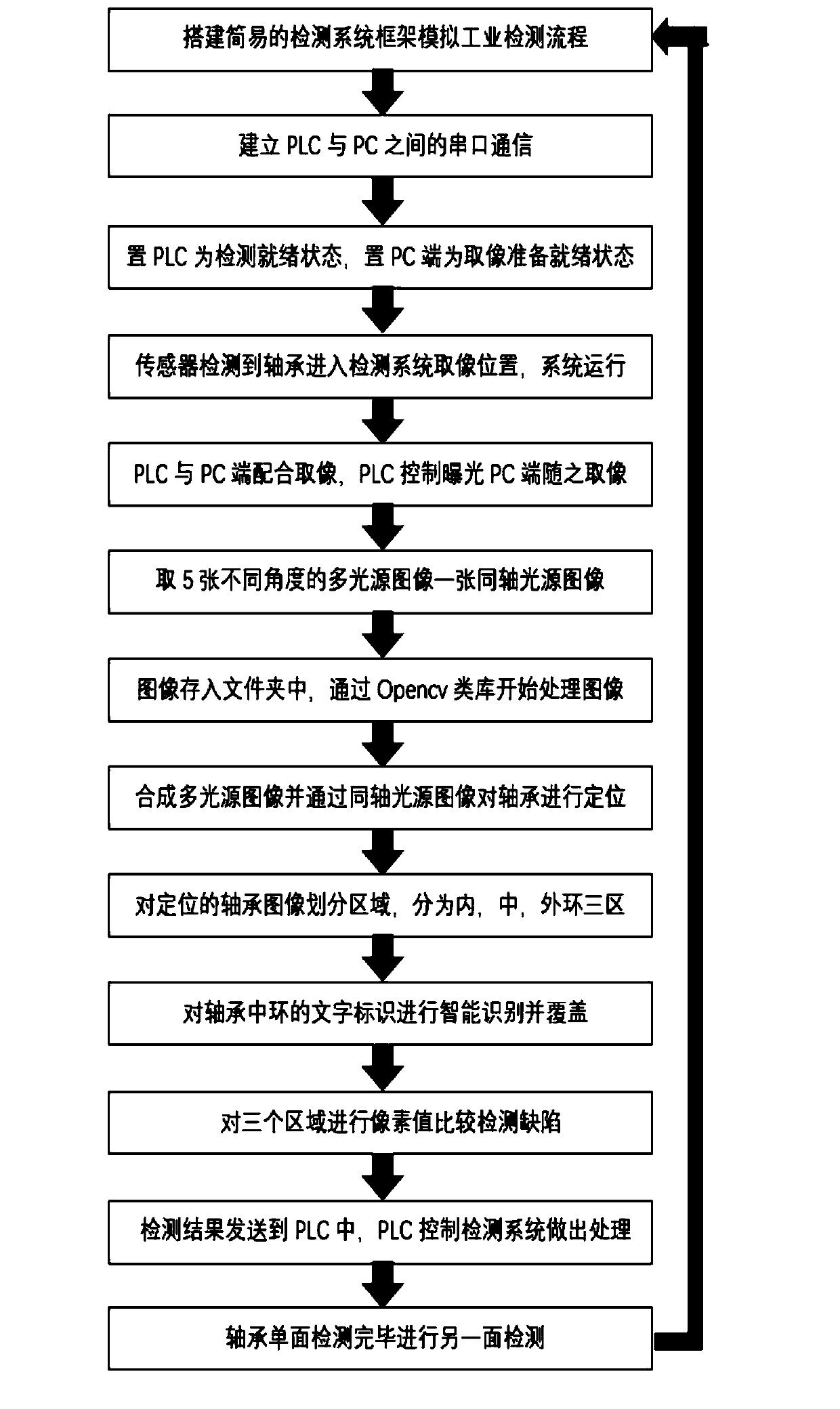

[0035] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

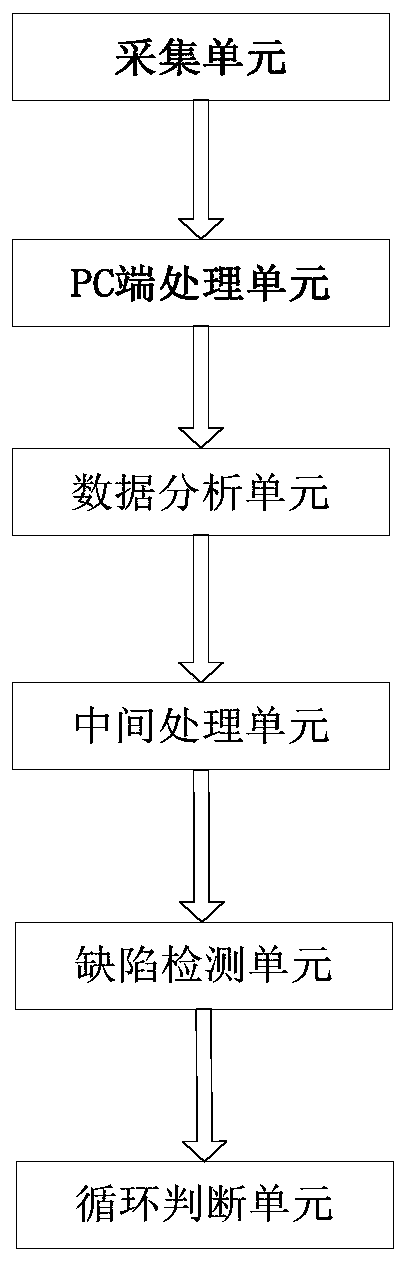

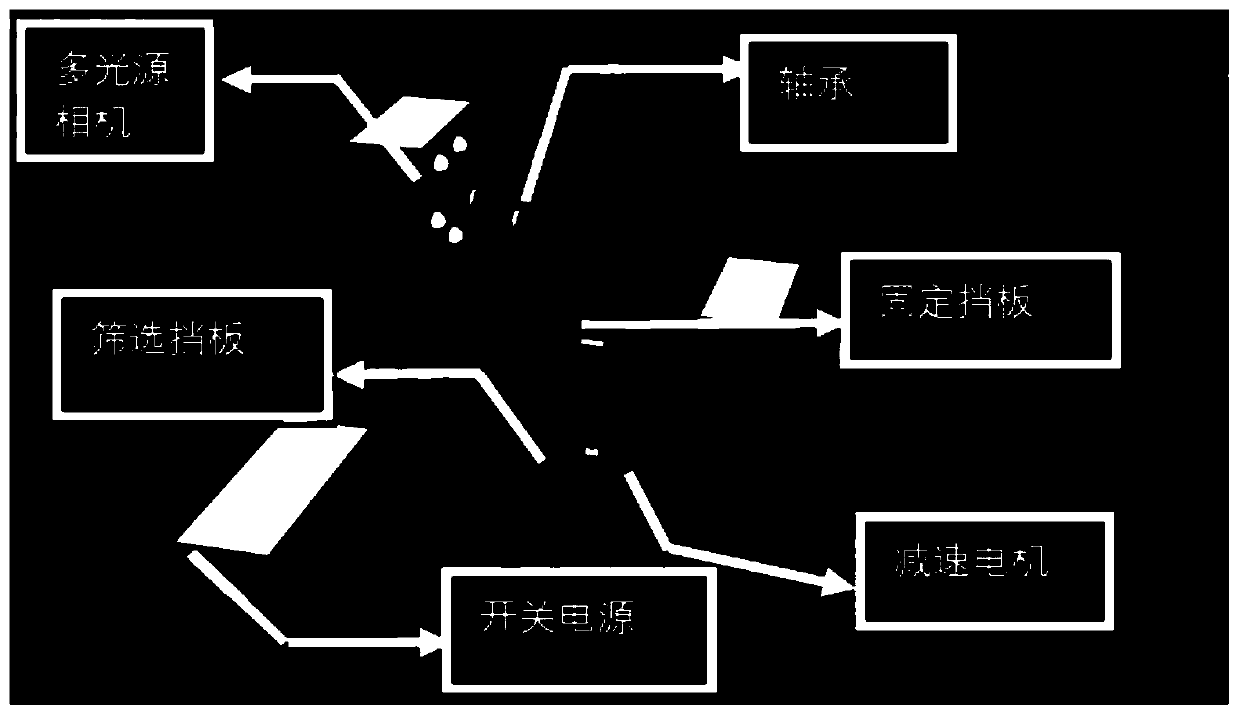

[0036] Such as Figure 1 to Figure 1 1 shows an automatic detection system for bearing defects based on multi-angle light source images, including an acquisition unit, a PC-side processing unit, a data analysis unit, an intermediate processing unit and a defect detection unit.

[0037] The acquisition unit first uses the same light source to take pictures of the bearing to be tested from multiple angles to obtain multiple grayscale images of the bearing to be tested, and then turns on multiple light sources at the same time to obtain a single coaxial light source image with clear characters. This system adopts multi-light source lighting conditions when collecting bearing images. The light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com