Dual-solenoid-coil type multi-parameter oil contamination detecting sensor

A detection sensor and double solenoid technology, applied in the direction of material impedance, material capacitance, etc., can solve problems such as dangerous working conditions, increase in solid particle size, system paralysis, etc., and achieve low cost, easy manufacture, and strong detection ability Effect

Inactive Publication Date: 2019-05-28

DALIAN MARITIME UNIVERSITY

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

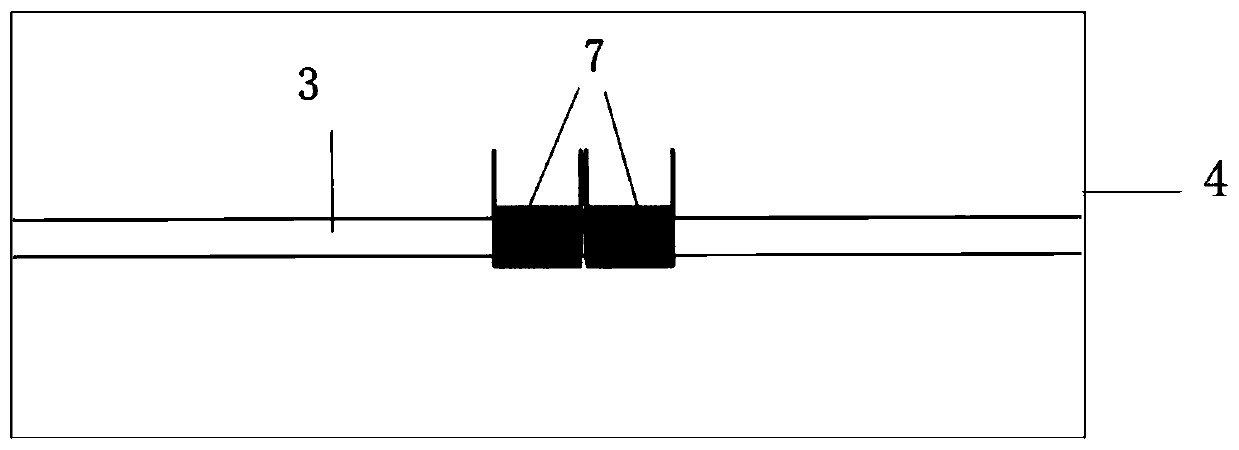

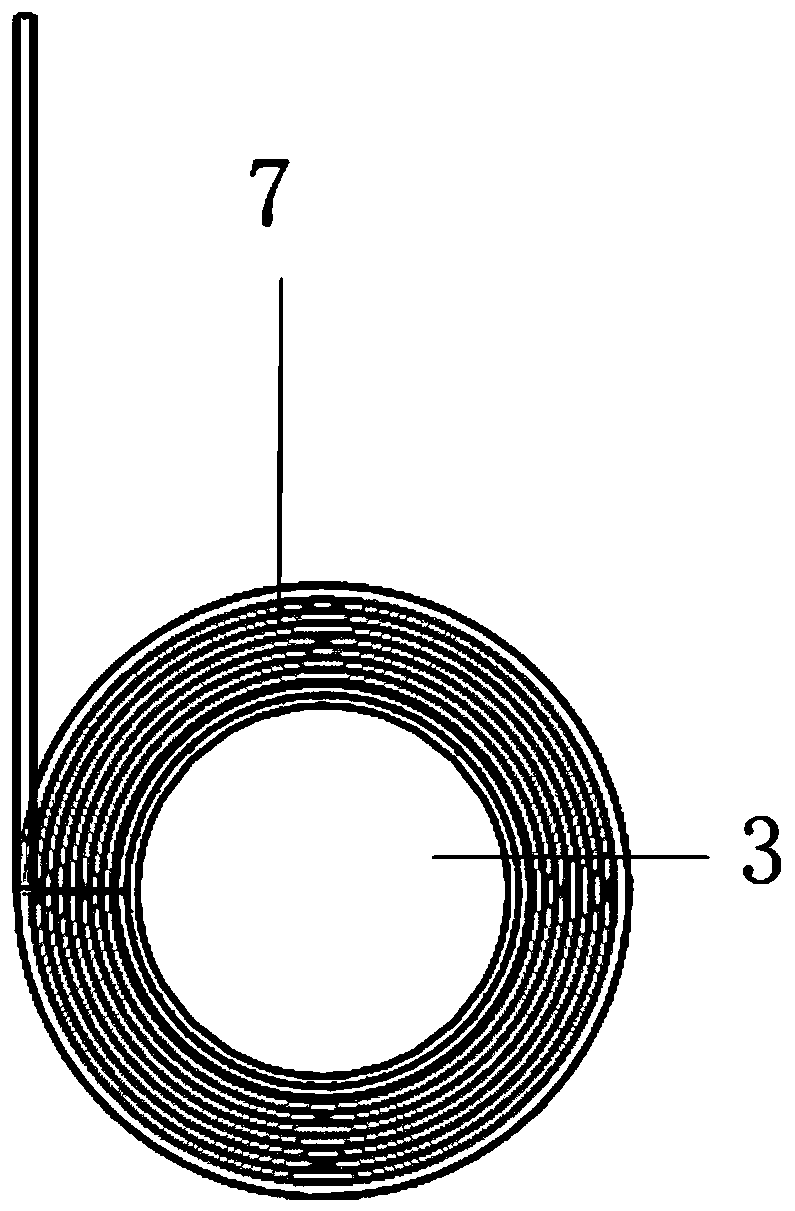

[0054] The present invention also provides a double solenoid coil type multi-parameter oil pollutant detection sensor. When in use, the sensor has two working modes: inductance detection mode and capacitance detection mode;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

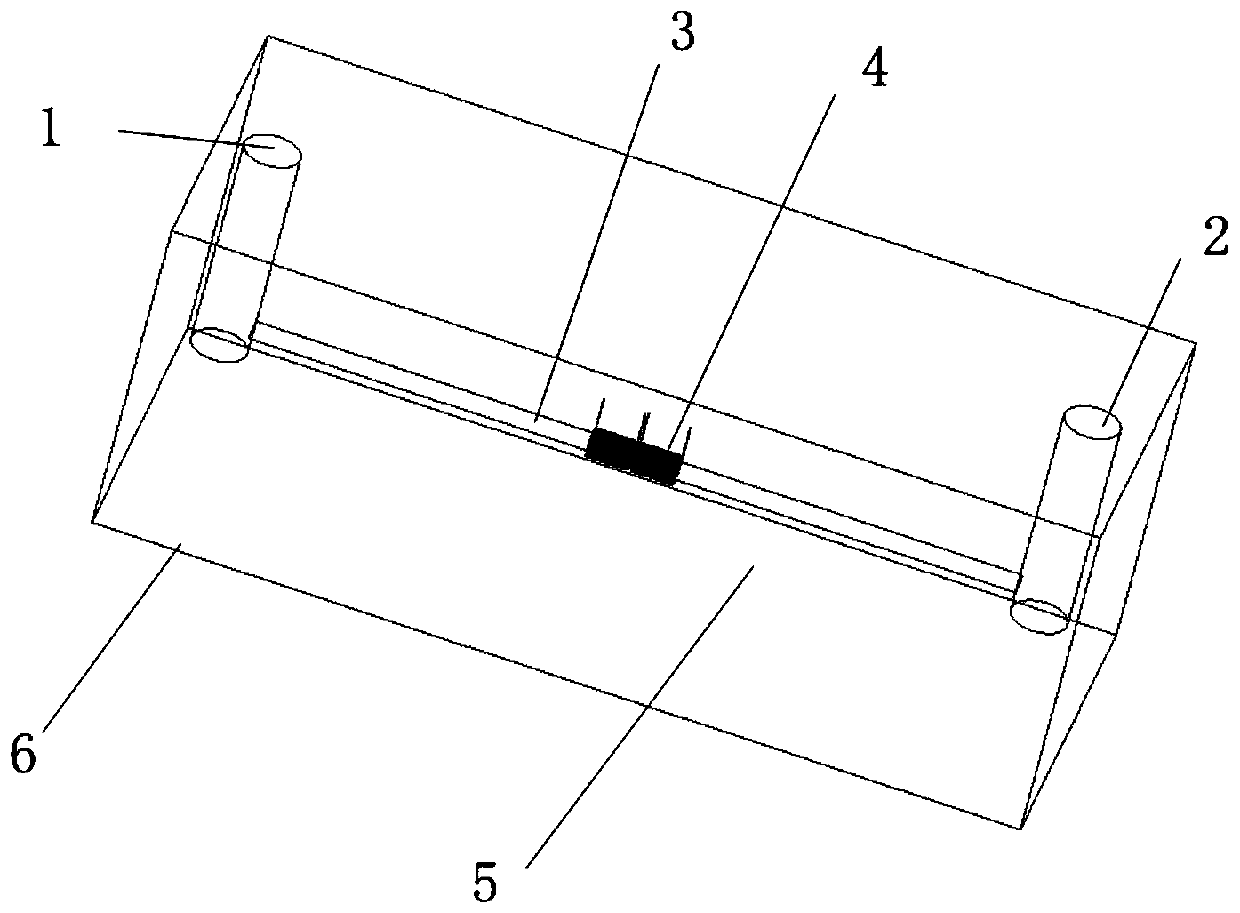

The invention provides a dual-solenoid-coil type multi-parameter oil contamination detecting sensor. The sensor comprises a micro-fluidics detecting chip, a sensing unit and an impedance analyzer; themicro-fluidics detecting chip comprises a glass substrate and a chip body arranged on the glass substrate; the chip body comprises a micro channel arranged on the chip body, one end of the micro channel is provided with an oil inlet, and the other end of the micro channel is provided with an oil outlet; a sensing unit is composed of two oppositely-distributed solenoid coils of the same structure,and the sensing unit is connected with the impedance analyzer through an insulation wire. According to the technical scheme, the problems that in the prior art, detection parameters are single, multiple contaminations cannot be effectively detected, and the detection precision is low.

Description

technical field [0001] The invention relates to the technical field of oil liquid detection, in particular to a double solenoid coil type multi-parameter oil liquid pollutant detection sensor. Background technique [0002] Wear is one of the most common failure forms that lead to abnormal operation and failure of various machinery and equipment. The inevitable product of internal friction and wear of equipment - wear particles suspended in the oil of the lubrication system, is a reflection of the internal wear condition (degree, location) of the equipment. and type) important information carrier. When the oil system is working normally, the particle size of the pollution particles is kept below 20μm. The abnormal wear of the machinery causes the particle size of the solid particles to increase rapidly, even reaching more than 100 μm, which is prone to dangerous working conditions and causes system paralysis. Therefore, the oil detection technology can detect large particle...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N27/02G01N27/22

Inventor 张洪朋白晨朝赵旭鹏曾霖虞子雷

Owner DALIAN MARITIME UNIVERSITY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com