Strain-gauge connecting fixing device for test-piece elasticity modulus test

An elastic modulus, fixing device technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test the strength of materials, etc., can solve the problems of long time consumption, tearing of wires, and high requirements for testing personnel welding technology, To achieve the effect of easy operation, improve the connection operation time, and solve the effect of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

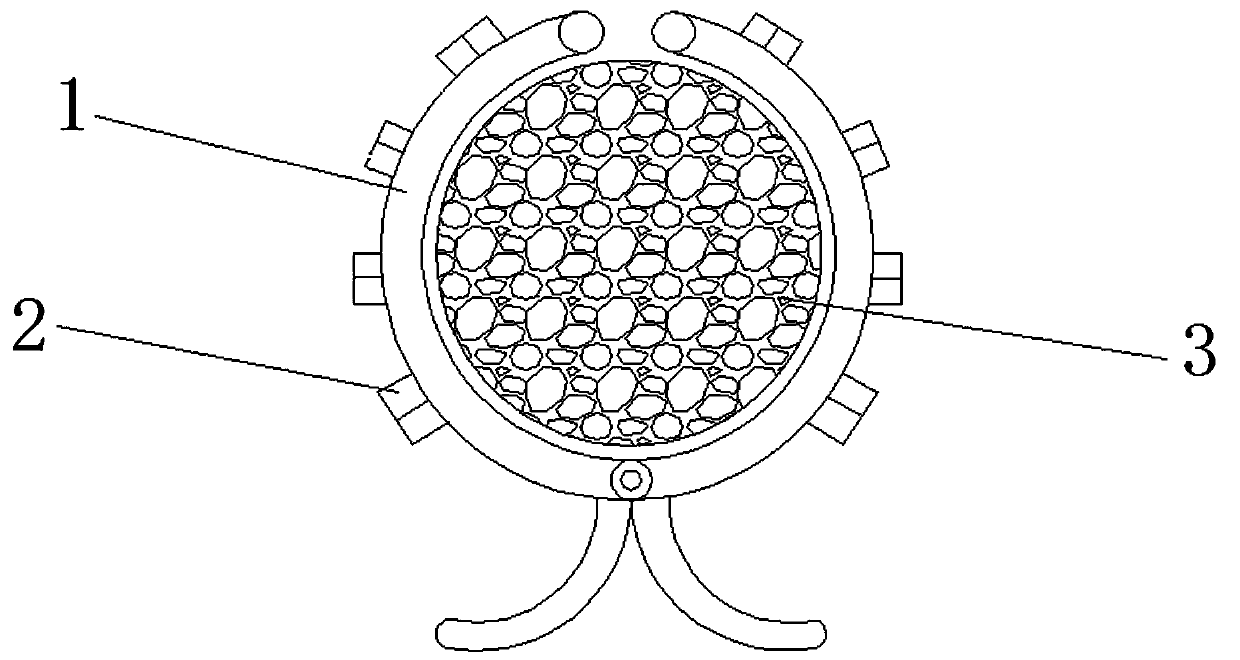

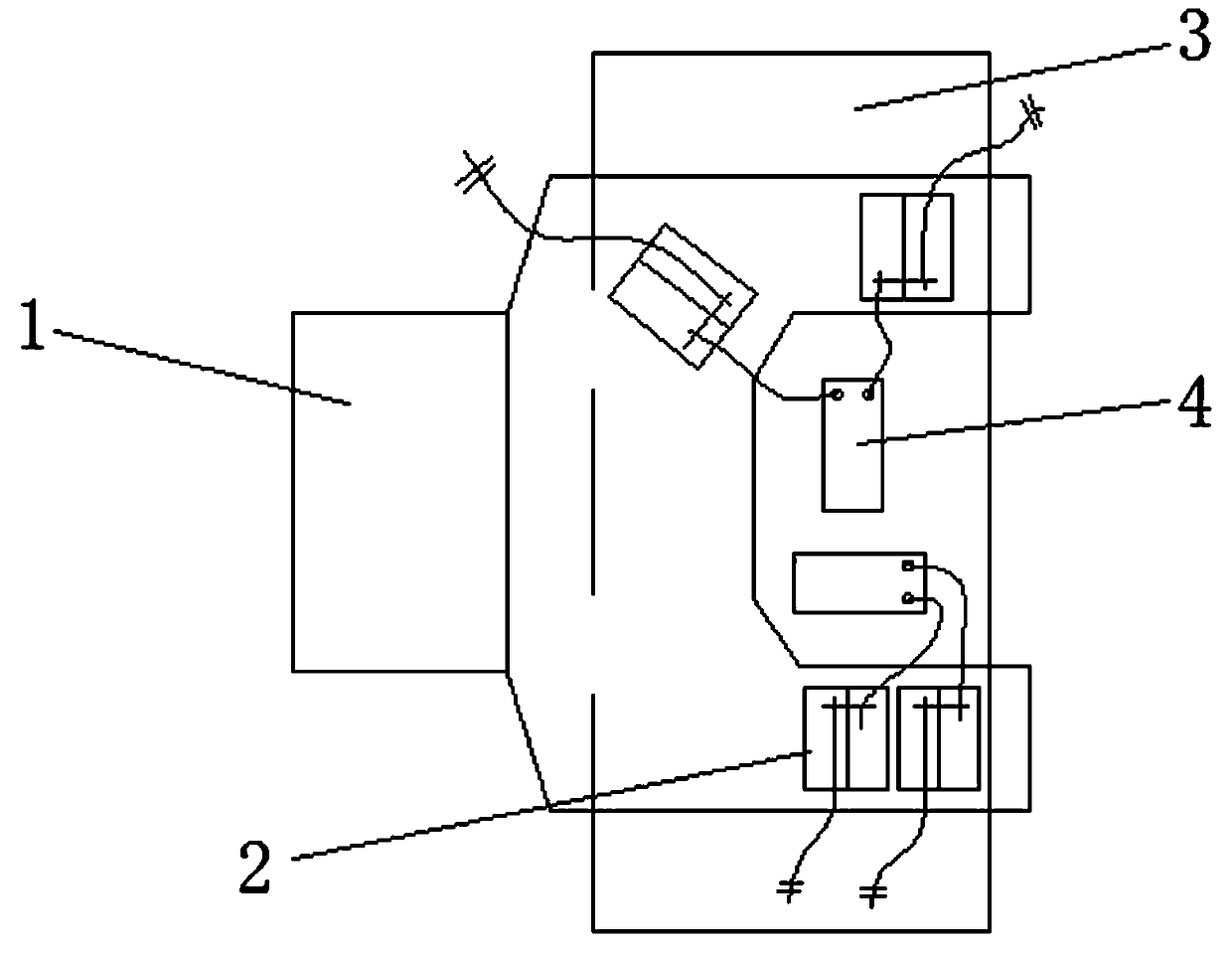

[0011] A strain gauge connecting and fixing device for the elastic modulus test of a specimen, comprising a chuck 1 and eight connection terminals 2, characterized in that:

[0012] The eight connection terminals 2 are respectively fixedly arranged on the set positions of the chuck 1 . The signal output end of each connection terminal 2 is connected with the signal input end of the peripheral tester through a corresponding wire. The handle of chuck 1 is fixedly installed on the support through the connecting rod. The above tester is a static resistance strain gauge.

[0013] The terminal blocks above are commercially available products, one-in-one-out terminal blocks of the WAGO brand, model 221-412, connection method: spring type connection.

[0014] Paste the strain gauge 4 on the tested piece 3, clamp the connecting clamp 1 on the tested piece 3, then insert the wire of the strain gauge 4 into the signal input end of the terminal 2, press the other end into the tester wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com