Combined support system for installation of large special-shaped components and method of use

A technology of special-shaped components and support systems, which is applied in the direction of building structure support, building structure support, building construction, etc., and can solve problems such as poor structural stability, high cost, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

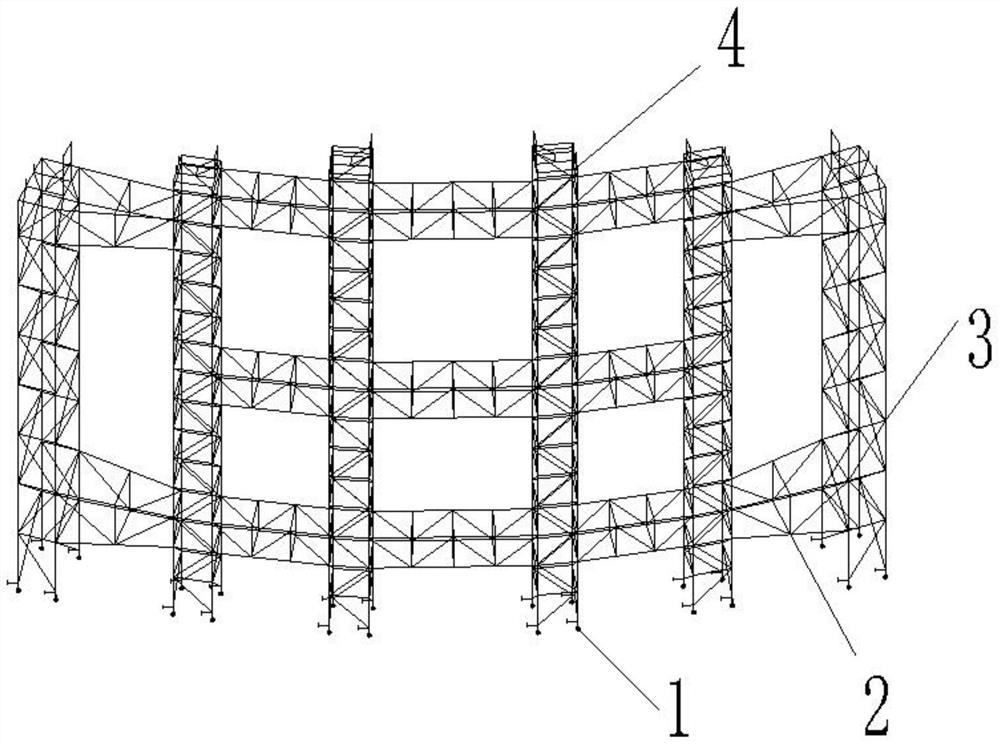

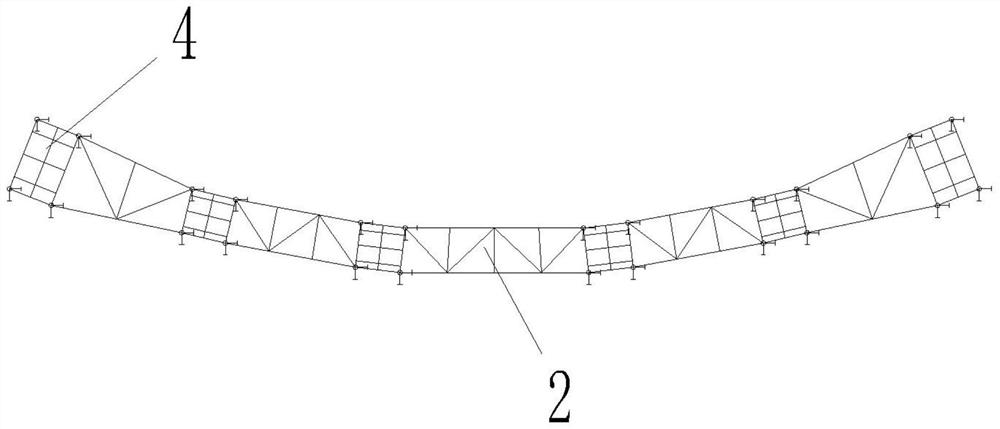

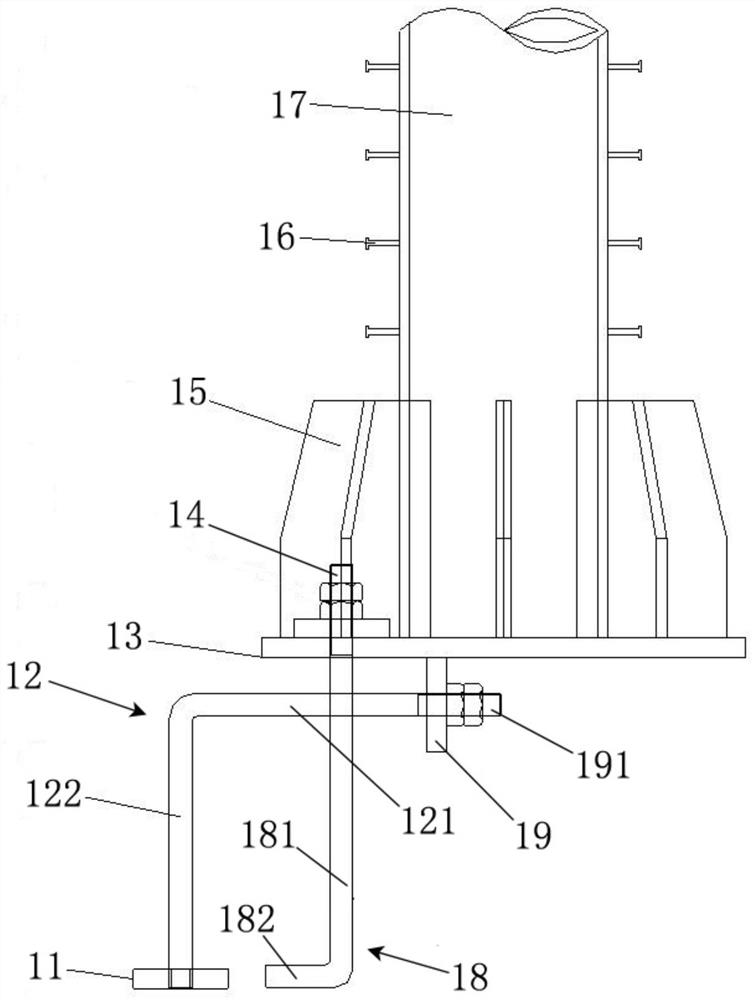

[0071] Such as Figure 1-22 As shown, the combined support system for the installation of large special-shaped components provided by the present invention has simple structure, scientific and reasonable design, convenient use, can effectively shorten the construction period, has strong structural stability, and can effectively reduce the difficulty of installing large special-shaped components. The entire support system can be reused, which can effectively reduce costs. The present invention includes an embedded structure 1, a connecting truss 2, a support adjustment block 4, and a support body. The support body includes more than two support standard sections 3, and all the support standard sections 3 are sequentially connected to form the support body. The sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com