Emulsified paraffin and preparation method thereof

A technology of emulsified paraffin and paraffin, applied in the field of emulsified paraffin and its preparation, can solve the problems of high reaction temperature, cumbersome process, cumbersome operation, etc., and achieve the effect of increasing potential, simple process and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The composition of raw materials is as follows:

[0043] A component:

[0044] Paraffin 100kg

[0045] B component:

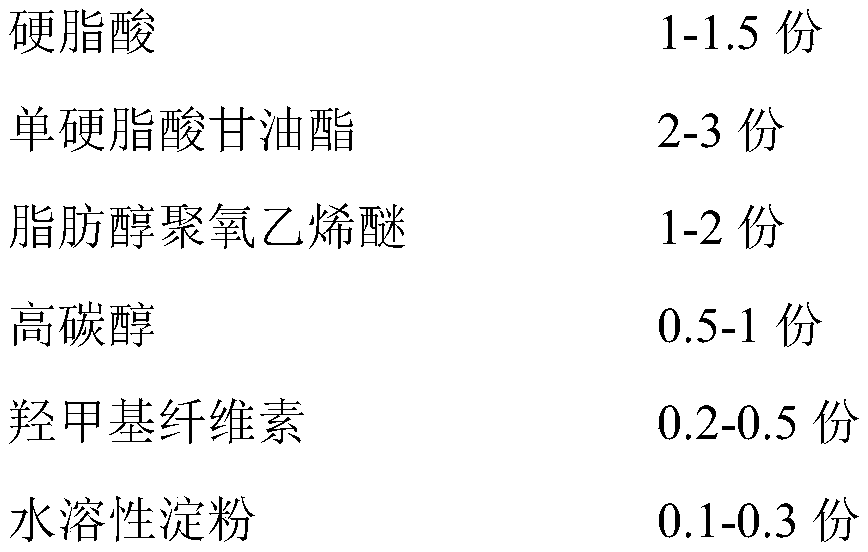

[0046]

[0047] C component:

[0048] Lye 7kg.

[0049] The preparation method is as follows:

[0050] (1) Weigh 100kg of component A, put it in a reaction kettle, heat and melt it for later use.

[0051] (2) Weigh 6kg of component B, add 30kg of water, control the temperature at 80°C, stir evenly, and the solution becomes viscous and transparent.

[0052] (3) Start the agitator (rotating at 100 rpm), and after the temperature in the kettle rises to 90°C, slowly add component B into the kettle and continue the reaction for 15 minutes.

[0053] (4) Slowly add 7kg of component C lye into the kettle in four times, and the emulsion changes from yellowish transparent → translucent → milky white and sticky → milky white and slightly blue, and the viscosity tends to the viscosity of the outer phase water. The water continues to stir, fully dilutes and...

Embodiment 2

[0055]The composition of raw materials is as follows:

[0056] A component:

[0057] Paraffin 105kg

[0058] B component:

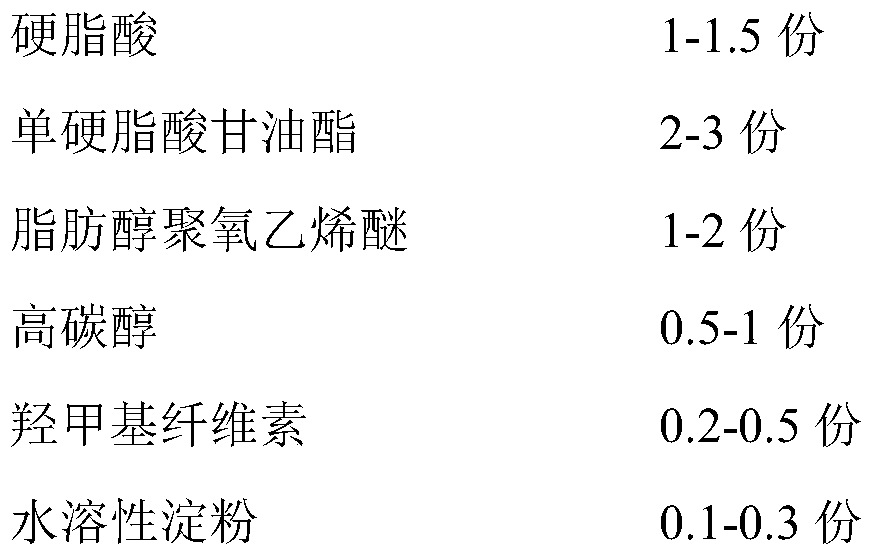

[0059]

[0060] C component:

[0061] Lye 7.5kg.

[0062] The preparation method is as follows:

[0063] (1) Weigh 105kg of component A, place it in a reaction kettle, heat and melt it for later use.

[0064] (2) Weigh 6.5kg of component B, add 35kg of water, control the temperature at 85°C, stir evenly, and the solution is viscous and transparent.

[0065] (3) Start the agitator (rotating speed 70 rpm), and after the temperature in the kettle rises to 95°C, slowly add component B into the kettle, and continue to react for 15 minutes.

[0066] (4) Slowly add 7.5kg of component C lye into the kettle in four times, and the emulsion changes from yellowish transparent → translucent → milky white and sticky → milky white and slightly blue, and the viscosity tends to the viscosity of the outer phase water. After emulsification for 30 minutes, add Cont...

Embodiment 3

[0068] The composition of raw materials is as follows:

[0069] A component:

[0070] Paraffin 110kg

[0071] B component:

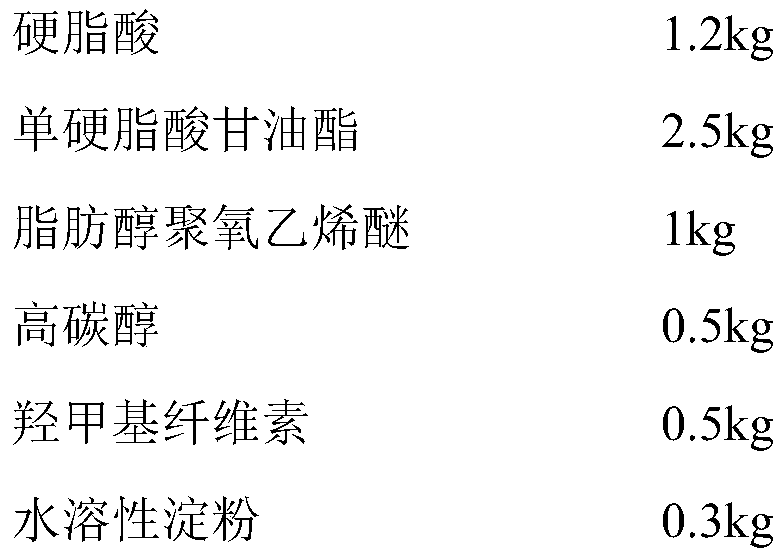

[0072]

[0073] C component:

[0074] Lye 8kg.

[0075] The preparation method is as follows:

[0076] (1) Weigh 110kg of component A, place it in a reaction kettle, heat and melt it for later use.

[0077] (2) Weigh 7kg of component B, add 40kg of water, control the temperature at 82°C, stir evenly, and the solution becomes viscous and transparent.

[0078] (3) Start the agitator (rotating speed: 80 rpm), and after the temperature in the kettle rises to 93°C, slowly add component B into the kettle, and continue to react for 15 minutes.

[0079] (4) Slowly add 8kg of component C lye into the kettle in four times, and the emulsion changes from yellowish transparent → translucent → milky white and sticky → milky white and slightly blue, and the viscosity tends to the viscosity of the outer phase water. The water continues to stir, fully dilutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com