Powder stock bin

A silo and powder technology, which is applied in the field of powder engineering, can solve the problems of uneven particle size distribution of product packaging and poor material feeding, so as to reduce segregation, promote overall flow pattern, and equipment failure rate. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

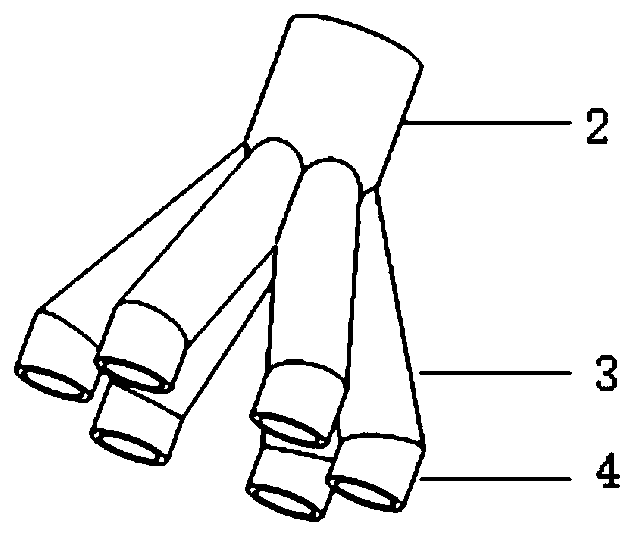

[0050] Such as figure 1 As shown, an industrial silo with a diameter of 3m, a height of the straight section of 8m, a full cone angle of 60°, and a silo outlet of 200mm is equipped with a new type of feed distributor, baffle and auxiliary fluid.

[0051] The feed distributor is connected to the end of the conveying pipeline through a flange. The height of the feed distributor from the top of the silo is 400mm, and the diameter of the feed pipe is 150mm. After circular processing, it is connected with the distribution pipe by welding. Each sector corresponds to a distribution pipe. The diameter of the distribution pipe is 60mm. Based on the good fluidity of the powder, the axial angle between the distribution pipe and the feed pipe is 50°. The outlet of the feed distributor is a vertical pipe with a diameter of 60mm and a length of 300mm.

[0052] The 6 baffles divide the straight section of the silo equally into 6 areas, that is, 6 small silos. The 6 baffles are welded tog...

Embodiment 2

[0057] Such as figure 1 As shown, an industrialized silo with a diameter of 3m, a straight section height of 8m, a full cone angle of 60°, and an outlet diameter of 200mm is equipped with a new type of feed distributor, baffle and auxiliary fluid.

[0058] The feed distributor is connected to the end of the conveying pipeline through a flange. The height of the feed distributor from the top of the silo is 400mm, and the diameter of the feed pipe is 150mm. After circular processing, it is connected with the distribution pipe by welding. Each sector corresponds to a distribution pipe. The diameter of the distribution pipe is 75mm. Based on the good fluidity of the powder, the axial angle between the distribution pipe and the feed pipe is 50°. The outlet of the feed distributor is a vertical pipe with a diameter of 75mm and a length of 300mm.

[0059] The 3 baffles divide the straight section of the silo into 3 areas equally, that is, 3 small silos. The three baffles are weld...

Embodiment 3

[0064] Such as figure 1 As shown, an industrialized silo with a diameter of 3m, a straight section height of 8m, a full cone angle of 60°, and an outlet diameter of 200mm is equipped with a new type of feed distributor, baffle and auxiliary fluid.

[0065] The feed distributor is connected to the end of the conveying pipe through a flange. The height of the feed distributor from the top of the silo is 400mm, and the diameter of the feed pipe is 150mm. After circular processing, it is connected with the distribution pipe by welding. Each sector corresponds to a distribution pipe. The diameter of the distribution pipe is 50mm. Based on the good fluidity of the powder, the axial angle between the distribution pipe and the feed pipe is 50°. The outlet of the feed distributor is a vertical pipe with a diameter of 50mm and a length of 200mm.

[0066] 8 baffles divide the straight section of the silo into 8 areas equally, that is, 8 small silos. The 8 baffles are welded to each o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com