Expansion valve assembly

An expansion valve and component technology, applied in refrigeration components, fluid circulation arrangements, refrigerators, etc., can solve the problems of inconvenient installation and disassembly of expansion valves, affecting the use of adjustment springs, and oxidation of adjustment springs and rubber seals. It has the effect of good installation, not easy to be caught, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

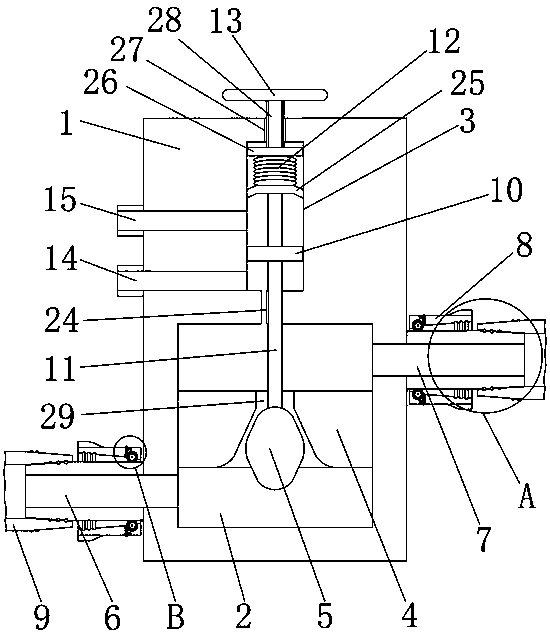

[0021] Such as figure 1 In the described embodiment, an expansion valve assembly includes a valve body 1, the upper half of the valve body 1 is provided with a piston chamber 3, the lower half of the valve body 1 is provided with a diversion chamber 2, and the piston chamber 3 It communicates with the diversion cavity 2, and the side of the valve body 1 is provided with a temperature sensing package interface 15, a balance tube interface 14, a refrigerant input port 6 and a refrigerant output port 7, and the temperature sensing package port 15 and the balance tube port 14 are connected to the piston cavity 3 connected, the refrigerant input port 6 and the refrigerant output port 7 are connected to the diversion chamber 2, the balance pipe interface 14 is placed on the side of the piston chamber 3 and close to the position of the diversion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com