Special composite starch for bean jelly and preparation method thereof

A technology of compound starch and jelly, applied in application, food science, food preservation, etc., can solve the problems of uneven quality, singleness, and large difference in taste of jelly, and achieve the effect of high nutritional value, easy to be absorbed, and easy to absorb and utilize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A special composite starch for jelly, the special composite starch for jelly comprises the following components by weight: 11 parts of broad bean starch; 12 parts of pea starch; 3 parts of red bean starch; 12 parts of organic acid; 2 parts of potassium chloride; 5 parts of n-butanol share.

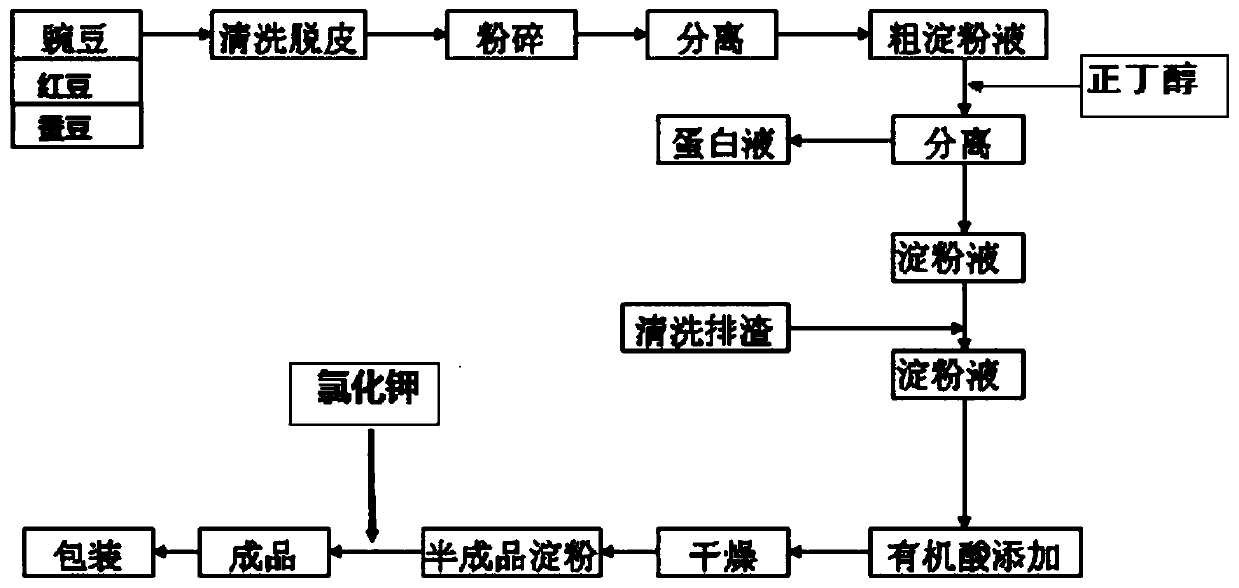

[0041] In addition, there is also provided a preparation method for compound starch special for jelly, comprising the steps of:

[0042] 1) Weigh the broad beans, peas and red beans, screen and remove the dust, and then peel them. The peeled broad beans, peas and red beans are then put into a pulverizer for ultra-fine grinding, and the pulverized coarse starch is put into a high-speed mixer for high-speed mixing. Enter the coarse separation to separate the coarse starch;

[0043] 2) put the coarse starch into the twin-screw extrusion, the twin-screw extrusion is divided into four sections with different temperatures, and the coarse starch is crushed again after extrusion;

[0044]...

Embodiment 2

[0056] A special compound starch for jelly, said compound starch for jelly comprises the following components by weight: 17 parts of broad bean starch; 18 parts of pea starch; 6 parts of red bean starch; 18 parts of organic acid; 4 parts of potassium chloride; 8 parts of n-butanol share.

[0057] In addition, there is also provided a preparation method for compound starch special for jelly, comprising the steps of:

[0058] 1) Weigh the broad beans, peas and red beans, screen and remove the dust and then peel them. The peeled broad beans, peas and red beans then enter the pulverizer for ultra-fine grinding, and put the coarse starch that has been crushed through a 140 mesh sieve into a high-speed mixer. Mix at high speed, and then enter the coarse separation to separate the coarse starch;

[0059]2) Put the coarse starch into the twin-screw extrusion, and the twin-screw extrusion is divided into four sections with different temperatures. The different temperatures of the four...

Embodiment 3

[0071] A special composite starch for jelly, the special composite starch for jelly comprises the following components by weight: 15 parts of broad bean starch; 16 parts of pea starch; 4 parts of red bean starch; 14 parts of organic acid; 3 parts of potassium chloride; 6 parts of n-butanol share.

[0072] In addition, there is also provided a preparation method for compound starch special for jelly, comprising the steps of:

[0073] 1) Weigh the broad beans, peas and red beans, screen and remove the dust and then peel them. The peeled broad beans, peas and red beans then enter the pulverizer for ultra-fine grinding, and put the coarse starch that has been crushed through a 140 mesh sieve into a high-speed mixer. Mix at high speed, and then enter the coarse separation to separate the coarse starch;

[0074] 2) Put the coarse starch into the twin-screw extrusion, and the twin-screw extrusion is divided into four sections with different temperatures. The different temperatures o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com