Angle-adjustable inclined plane anchor rod tray

A pallet and slope technology, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of deformation and fracture of the connecting surface, weak bearing capacity, poor adaptability, etc., and achieve a wide range of slope angles, strong bearing capacity, and structural stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

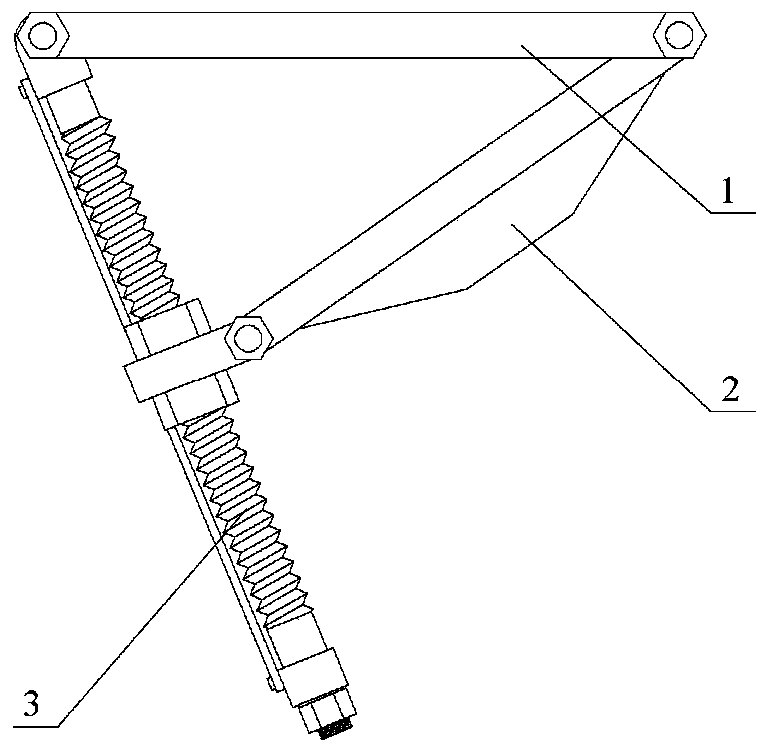

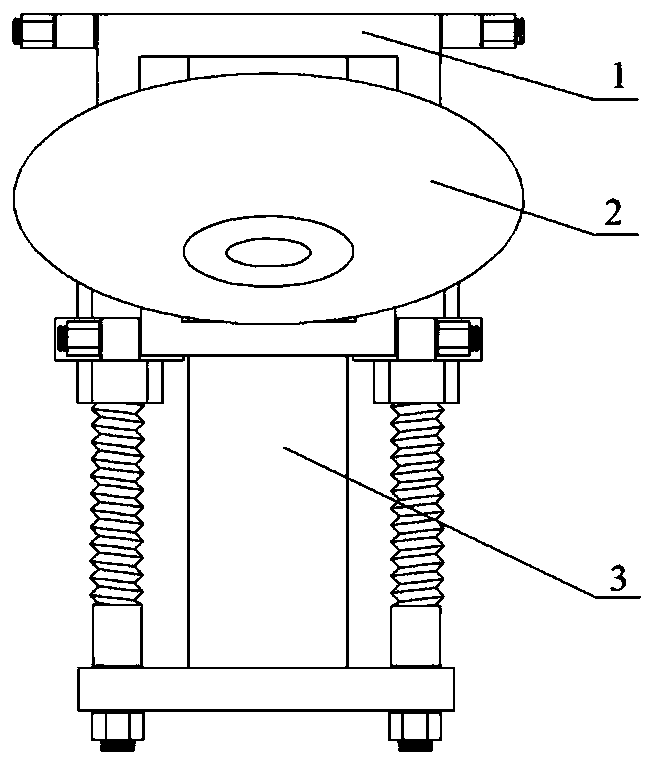

[0034] An angle-adjustable sloped anchor tray. Such as figure 1 , figure 2 , image 3 As shown, the inclined anchor pallet is composed of a pallet top plate 1, a pallet frame 2 and a support frame 3. The upper end of the tray frame 2 is connected by bolts with one end of the tray top plate 1, the other end of the tray top plate 1 is connected with the upper end of the support frame 3 by bolts, and the middle part of the support frame 3 is connected with the lower end of the tray frame 2 by bolts.

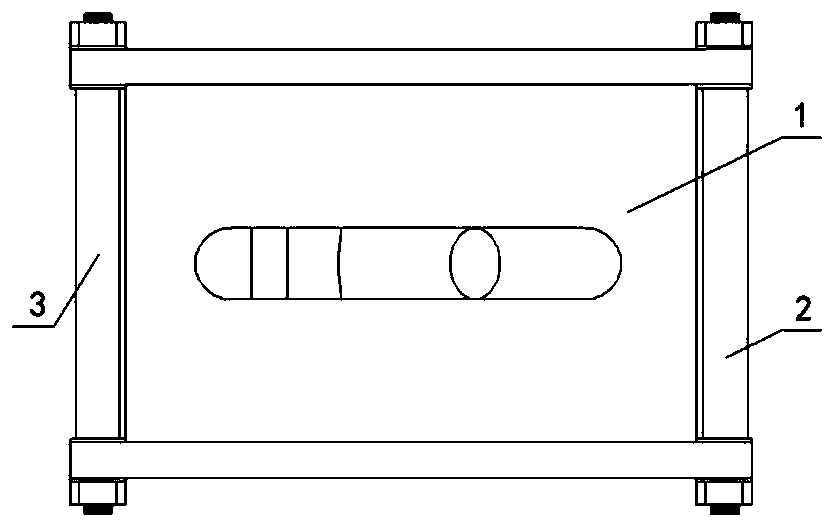

[0035] Such as Figure 4 and Figure 5 As shown, the pallet top plate 1 is composed of a rectangular plate 4 and two reinforcing rods 5 . A strip-shaped hole 6 is opened at the centroid of the rectangular plate 4 , and the long sides of the strip-shaped hole 6 are parallel to the long sides of the rectangular plate 4 . The two long sides of the rectangular plate 4 are symmetrically fixed with reinforcing rods 5, the two ends of the reinforcing rods 5 protrude from the rectang...

Embodiment 2

[0045] An angle-adjustable sloped anchor tray. Except following technical parameter, all the other are with embodiment 1:

[0046] The lengths of the two protruding ends of the reinforcing rod 5 are both 18-20mm;

[0047] The diameter of the large surface of the circular table 9 is 0.8 to 0.85 times of the axial length of the frame 8 .

[0048] Compared with the prior art, this specific embodiment has the following positive effects:

[0049] When this specific embodiment is in use, the rectangular plate 4 of the tray top plate 1 is first pressed against the rock wall 18, and the position of the hinged collar 13 on the threaded rod 14 is adjusted so that the centerline of the anchor hole 10 of the tray frame 2 is in line with the rock wall 18. The center line of the drilling hole on the wall 18 coincides, then adjust the collar fixing nut 12, clamp the hinged collar 13, and then connect the tray top plate 1 and the tray frame 2, the tray top plate 1 and the support frame 3, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com