Moth-proof mildew-proof anion composite flooring

A technology of composite flooring and negative ions, applied in coatings, starch coatings, protein coatings, etc., can solve problems such as little effect, and achieve the effect of comfortable feet and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

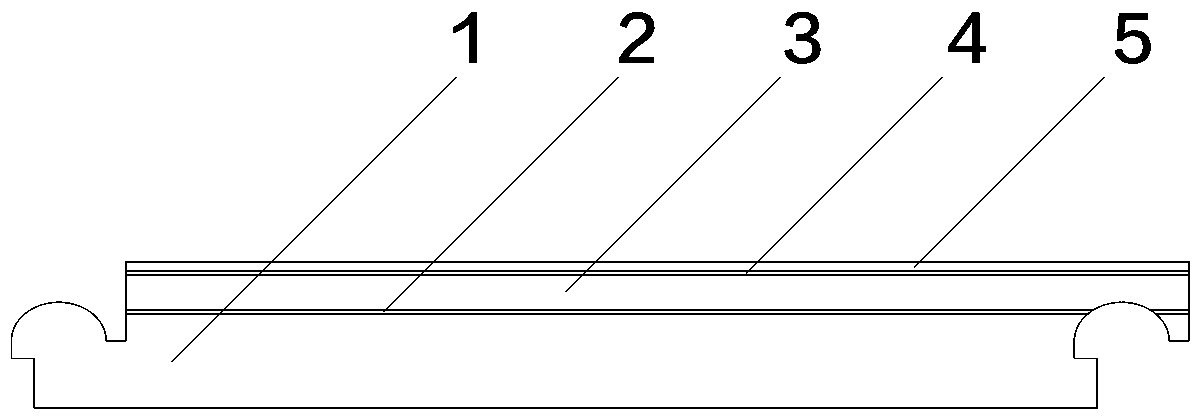

[0019] Embodiment 1: a kind of anti-insect and mildew-proof negative ion composite floor is characterized in that comprising insect-proof and mildew-proof layer, negative ion adhesive layer, substrate layer, decorative layer, paint layer.

[0020] The insect-proof and mildew-proof layer described in the present embodiment comprises 35 parts of wormwood, 10 parts of camphor wood, 5 parts of Zanthoxylum bungeanum, and 35 parts of bark. 3 parts of clove, 1 part of mint, 16 parts of polyurethane adhesive, 1 part of preservative, 2 parts of antifungal agent, 5 parts of tourmaline powder, 5 parts of far-infrared powder, 2 parts of additives, and the following steps are also included; (1) The wormwood, camphor wood, Chinese prickly ash, oak bark, clove, and mint are crushed, cone-milled, screened, then dried and steel-milled to obtain a diameter of 0.08mm and a moisture content of 13%. Particles with a bulk density of 55g / dm3; (2) Add polyurethane glue, mix evenly and stir for 45 min...

Embodiment 2

[0027] Embodiment 2: An insect-proof, mildew-proof negative ion composite floor is characterized in that it comprises an insect-proof and mildew-proof layer, an anion glue layer, a base material layer, a decorative layer, and a paint layer.

[0028] The insect-proof and mildew-proof layer described in the present embodiment comprises 35 parts of wormwood, 12 parts of camphor wood, 5 parts of Zanthoxylum bungeanum, and 27 parts of bark. 5 parts of clove, 3 parts of mint, 19 parts of polyurethane adhesive, 2 parts of preservative, 2 parts of antifungal agent, 5 parts of tourmaline powder, 5 parts of far-infrared powder, 3 parts of auxiliary agent, and the following steps are also included; (1) The wormwood, camphor wood, Chinese prickly ash, oak bark, clove, and mint are crushed, cone-milled, screened, then dried and steel-milled to obtain a diameter of 0.08mm and a moisture content of 13%. Particles with a bulk density of 57g / dm3; (2) Add polyurethane glue, mix evenly and stir ...

Embodiment 3

[0035] Embodiment 3: An insect-proof, mildew-proof negative ion composite floor is characterized in that it comprises an insect-proof and mildew-proof layer, an anion glue layer, a base material layer, a decorative layer, and a paint layer.

[0036] The insect-proof and mildew-proof layer described in the present embodiment comprises 31 parts of wormwood, 8 parts of camphor wood, 5 parts of Zanthoxylum bungeanum, and 35 parts of bark. 3 parts of clove, 3 parts of mint, 18 parts of polyurethane adhesive, 2 parts of preservative, 2 parts of antifungal agent, 4 parts of tourmaline powder, 5 parts of far-infrared powder, 3 parts of auxiliary agent, and the following steps are also included; (1) The wormwood, camphor wood, Chinese prickly ash, oak bark, clove, and mint are crushed, cone-milled, screened, then dried and steel-milled to obtain a diameter of 0.07mm and a moisture content of 13%. Particles with a bulk density of 57g / dm3; (2) Add polyurethane glue, mix evenly and stir f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com