A kind of preparation method of trapezoidal branched chain modified siloxane polymer supercritical carbon dioxide thickener

A carbon dioxide and polymer technology, applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve problems hindering the application and promotion of fracturing stimulation, reduce the amount of co-solvent, and reduce production costs , the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

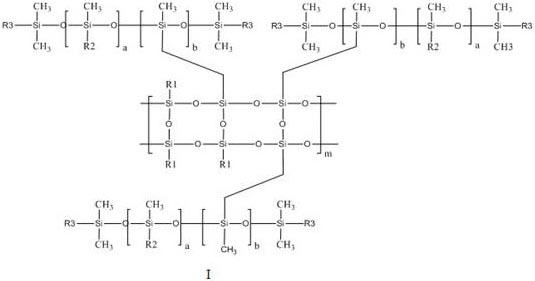

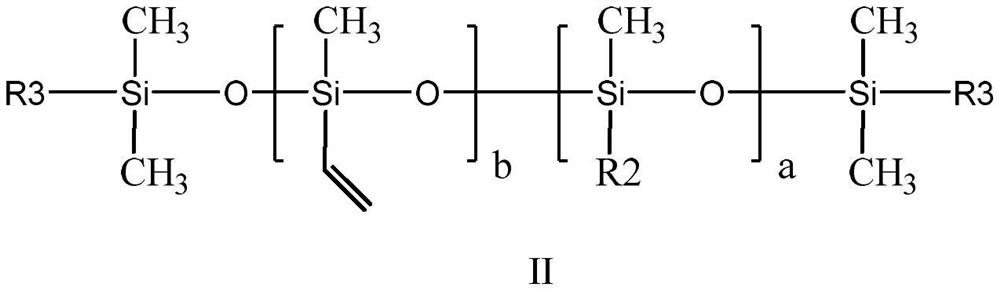

[0011] Technical scheme of the present invention is as follows:

[0012] A preparation method of a trapezoidal branched modified siloxane polymer supercritical carbon dioxide thickener, comprising the steps of:

[0013] (1) Preparation of functional group-terminated linear polydimethylsiloxane polymer

[0014] Add cyclic siloxane, small molecule end-capping agent, toluene and basic catalyst into the reaction kettle, blow in nitrogen, seal the reaction kettle, react at 100-115°C for 2-11h, and then raise the temperature to 140°C React at -155°C for 30-40 minutes, cool down to room temperature, remove the toluene solvent and low-molecular siloxane low boilers in a vacuum, and obtain a functional group-terminated linear polydimethylsiloxane polymer;

[0015] The cyclic siloxane is octamethylcyclotetrasiloxane, tetramethyltetravinylcyclotetrasiloxane, octavinylcyclotetrasiloxane, tetramethyltetrahydrocyclotetrasiloxane, six One or more of methyldihydrocyclotetrasiloxane, hexamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com