A kind of anti-electromagnetic radiation waterproof and breathable film material and its preparation method and application

An anti-electromagnetic radiation, waterproof and breathable technology, applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, chemical instruments and methods, can solve the problems of poor waterproof and air permeability, and shielding materials that cannot meet the protection requirements, so as to reduce the impact , good waterproof and breathable performance, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

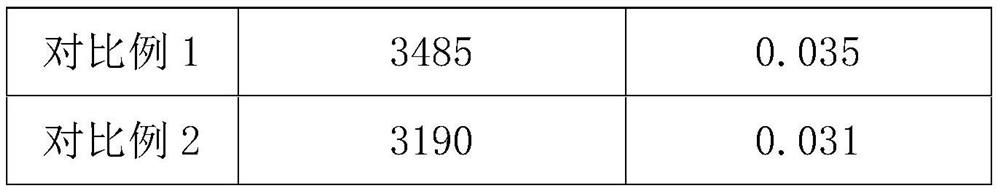

Embodiment 1

[0025] An anti-electromagnetic radiation waterproof and breathable film material, which is composed of the following raw materials in proportion by weight: 100 parts of water-based polyurethane resin, 80 parts of film-forming solvent, 15 parts of graphene oxide, 5 parts of catalyst, 3 parts of emulsifier, and matting powder 1 part, 2 parts of deionized water, 90 parts of epoxy resin, 60 parts of acetone, 10 parts of conductive carbon powder, 4 parts of dicyandiamide, 20 parts of plasticizer, and 3 parts of finishing agent.

[0026] The catalyst is a combination of at least two of dibutyltin dilaurate, stannous octoate, and dibutylene diacetate; the plasticizer is dioctyl phthalate; the finishing agent is nanoscale iron oxide, nanoscale silver, Copper and nickel metal particles are mixed with dispersant and stabilizer at a weight ratio of 12:7:70. The dispersant is calcium stearate and the stabilizer is organic antimony.

[0027] A preparation method of an electromagnetic radia...

Embodiment 2

[0039] An anti-electromagnetic radiation waterproof and breathable film material, which is composed of the following raw materials in parts by weight: 110 parts of water-based polyurethane resin, 100 parts of film-forming solvent, 17 parts of graphene oxide, 6 parts of catalyst, 4 parts of emulsifier, and matting powder 1.5 parts, 2.5 parts of deionized water, 105 parts of epoxy resin, 70 parts of acetone, 13 parts of conductive carbon powder, 5 parts of dicyandiamide, 25 parts of plasticizer, and 4.5 parts of finishing agent.

[0040] The catalyst is a combination of at least two of dibutyltin dilaurate, stannous octoate, and dibutylene diacetate; the plasticizer is dioctyl phthalate; the finishing agent is nanoscale iron oxide, nanoscale silver, Copper and nickel metal particles are mixed with dispersant and stabilizer at a weight ratio of 15:10:75. The dispersant is calcium stearate and the stabilizer is organic antimony.

[0041] A preparation method of an electromagnetic ...

Embodiment 3

[0053] An anti-electromagnetic radiation waterproof and breathable film material, which is composed of the following raw materials in parts by weight: 120 parts of water-based polyurethane resin, 120 parts of film-forming solvent, 19 parts of graphene oxide, 7 parts of catalyst, 5 parts of emulsifier, and matting powder 2 parts, 3 parts of deionized water, 120 parts of epoxy resin, 80 parts of acetone, 15 parts of conductive carbon powder, 6 parts of dicyandiamide, 30 parts of plasticizer, and 6 parts of finishing agent.

[0054] The catalyst is a combination of at least two of dibutyltin dilaurate, stannous octoate, and dibutylene diacetate; the plasticizer is dioctyl phthalate; the finishing agent is nanoscale iron oxide, nanoscale silver, Copper and nickel metal particles are mixed with dispersant and stabilizer at a weight ratio of 18:13:80. The dispersant is calcium stearate and the stabilizer is organic antimony.

[0055] A preparation method of an electromagnetic radiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com