An automatic lifting energy-saving moisture-proof power distribution cabinet

A lift-type, power distribution cabinet technology, applied in the direction of substation/distribution device casing, etc., can solve the problems of easy aging of internal circuits, affect safety, affect heat dissipation, etc., and achieve high efficiency to ensure internal drying and prevent dust and impurities from entering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

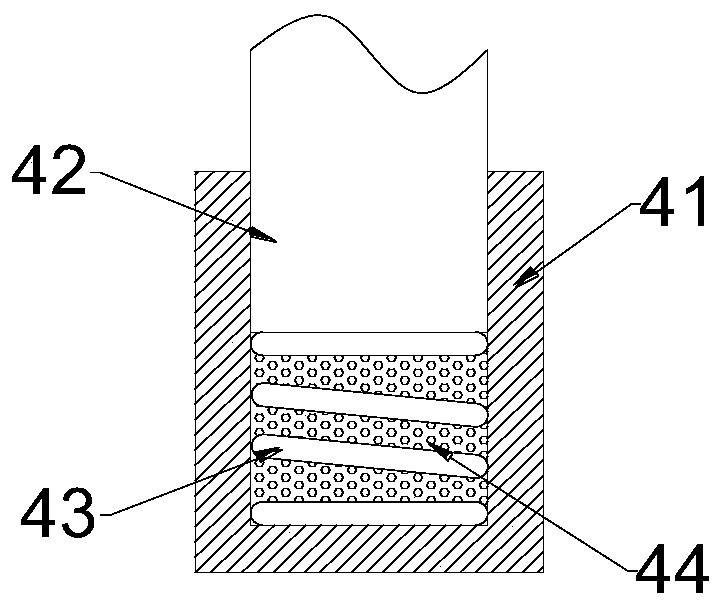

[0026] see image 3 , in the embodiment of the present invention, an automatic lifting type energy-saving and moisture-proof power distribution cabinet, on the basis of embodiment 1, the telescopic support rod 4 is composed of a sleeve 41, a sliding rod 42 and a spring 43, and the sleeve 41 It is connected with the sliding rod 42 through a sliding socket, the bottom of the sliding rod 42 is elastically connected with the inner bottom of the sleeve 41 through a spring 43, and the lower end of the sliding rod 42 is connected to the inner bottom of the sleeve 41. The cavities are filled with crushed foam 44 .

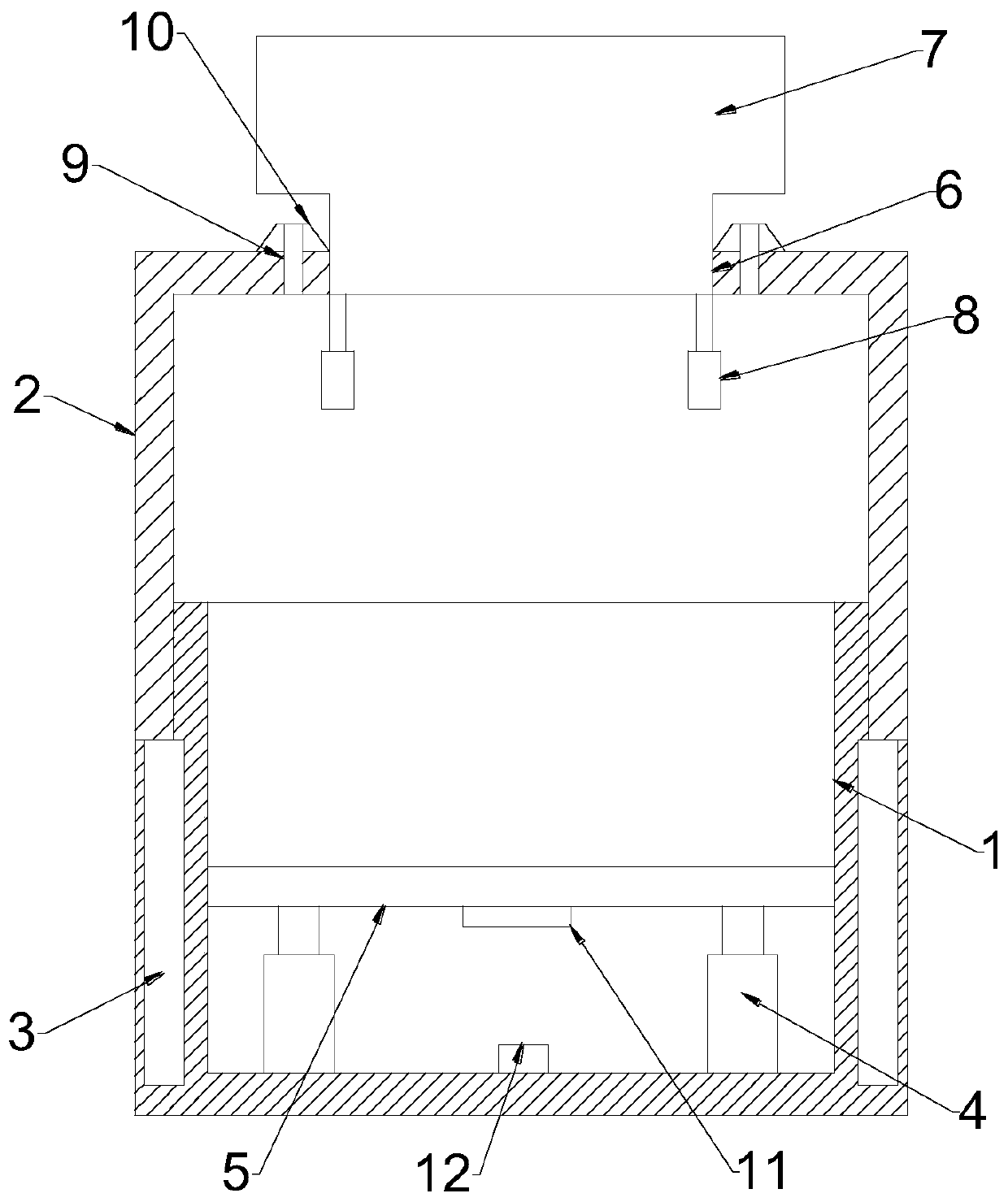

[0027] The working principle of the present invention is: when in use, the first electric telescopic rod 3 is driven up and down to control the installation of equipment on the placement plate 5. When the equipment is running, the telescopic support rod 4 can be used for efficient vibration reduction. At the same time, the lower casing 1 and the upper casing The assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com