Preparation method of moisture stimulus responsive type transparent cellulose membrane driver

A stimuli-responsive, cellulose film technology, which is applied in manufacturing tools, wood processing appliances, wood impregnation, etc., can solve the problems of non-renewable materials, poor interface bonding of double-layer composite structures, etc., and achieves simple preparation methods, good applicability, The effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

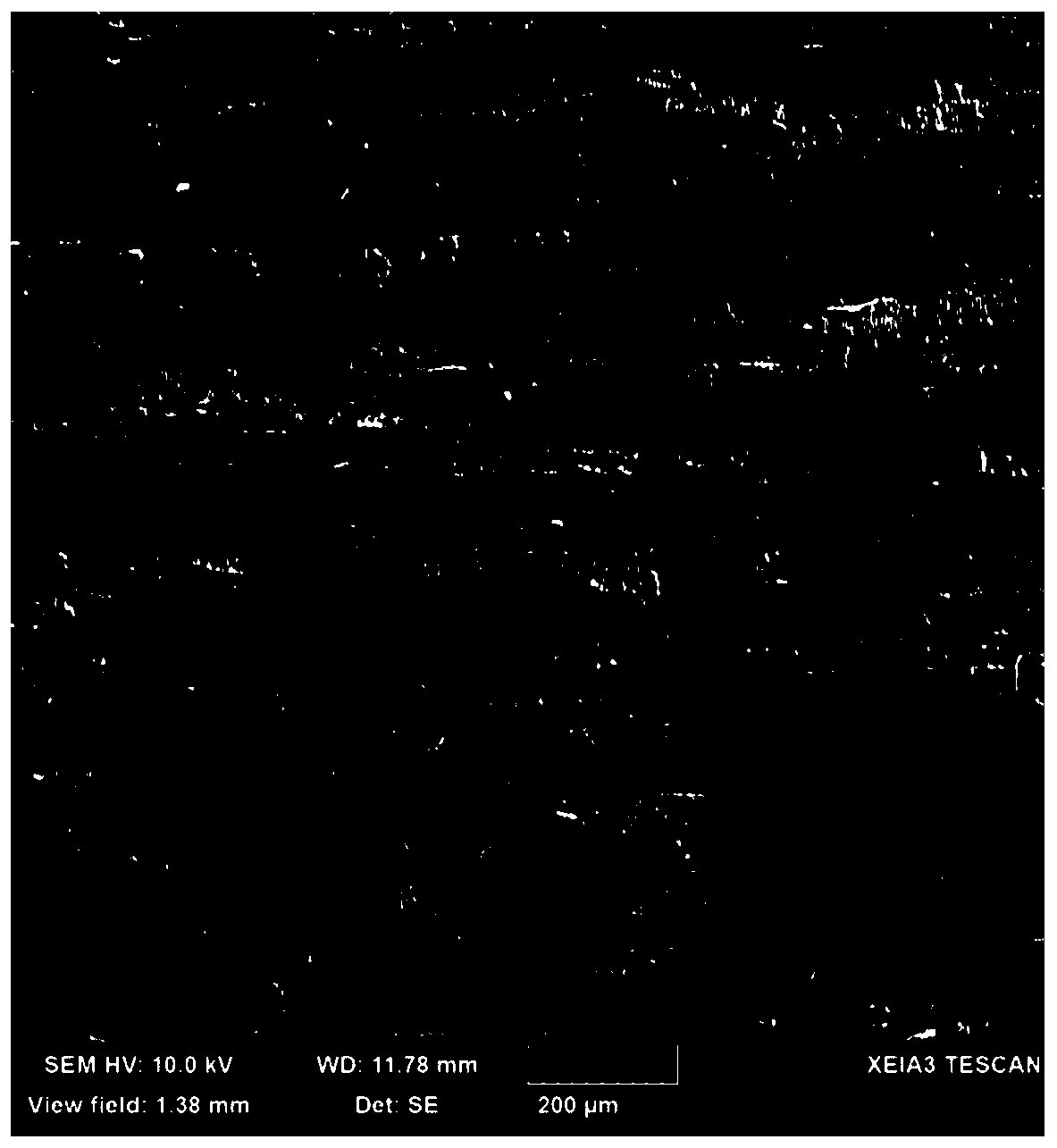

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: The method for preparing a humidity stimulus-responsive transparent cellulose membrane driver in this embodiment includes the following steps:

[0031] 1. Weigh 0.1%-5% of nanoparticles, 0.1%-2% of surface modifier and the rest of toluene according to mass percentage, mix and stir for 72-76h, then wash with acetone, and centrifuge at 8000-9000rpm for 3 -5 times, and then dried at 80-85°C for 12-14h to obtain reagent A;

[0032] 2. Weigh 1%-50% hydrophobic polymer resin, 0.1%-1% reagent A and the rest of the solvent according to mass percentage, stir at room temperature for 0.1-0.2 hours after mixing, and ultrasonically for 0.5-1 hour. The functional reagent B is obtained;

[0033] 3. Soak the wood veneer with a string-cut surface in sodium hypochlorite, and place it at room temperature for 6-7 hours; then, remove the sodium hypochlorite, add new sodium hypochlorite to continue soaking for 6-7 hours, and repeatedly replace the sodium hypochlorite 5-10 time...

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the nanoparticles in step 1 are SiO 2 , Ag, Cu, CuO, TiO 2 , One or several mixtures of ZnO in any ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment is different from Embodiment 2 in that: the particle size of the nanoparticles is 10-500 nm. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com