Low-temperature heat-not-burn electronic cigarette heating element and constant-temperature control device

A technology of low-temperature baking and constant temperature control, which is applied in the fields of tobacco, smokers’ supplies, applications, etc. It can solve the problems of electronic cigarettes with larger appearance and volume, increased connection points and failures, inconvenient miniaturization of heating elements, etc., and achieves compact structure, The effect of reducing the probability of failure and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

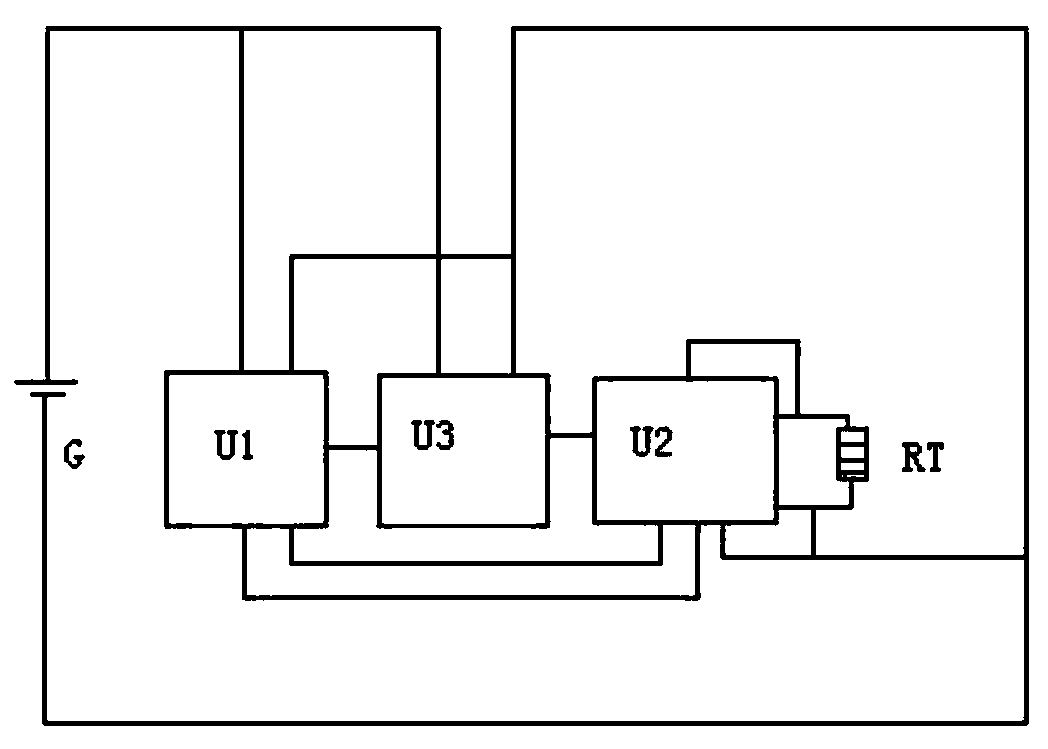

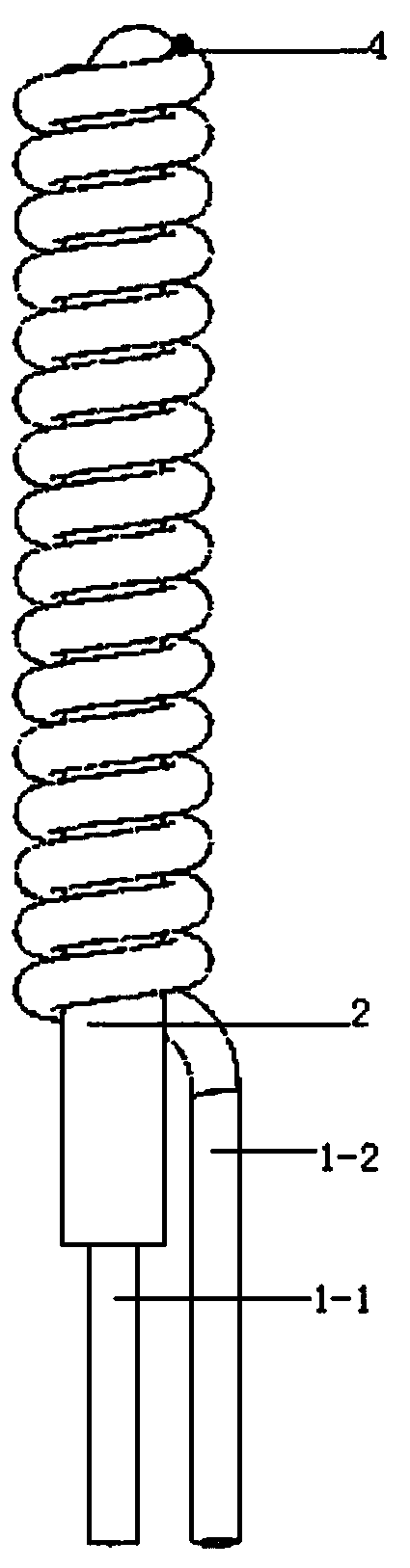

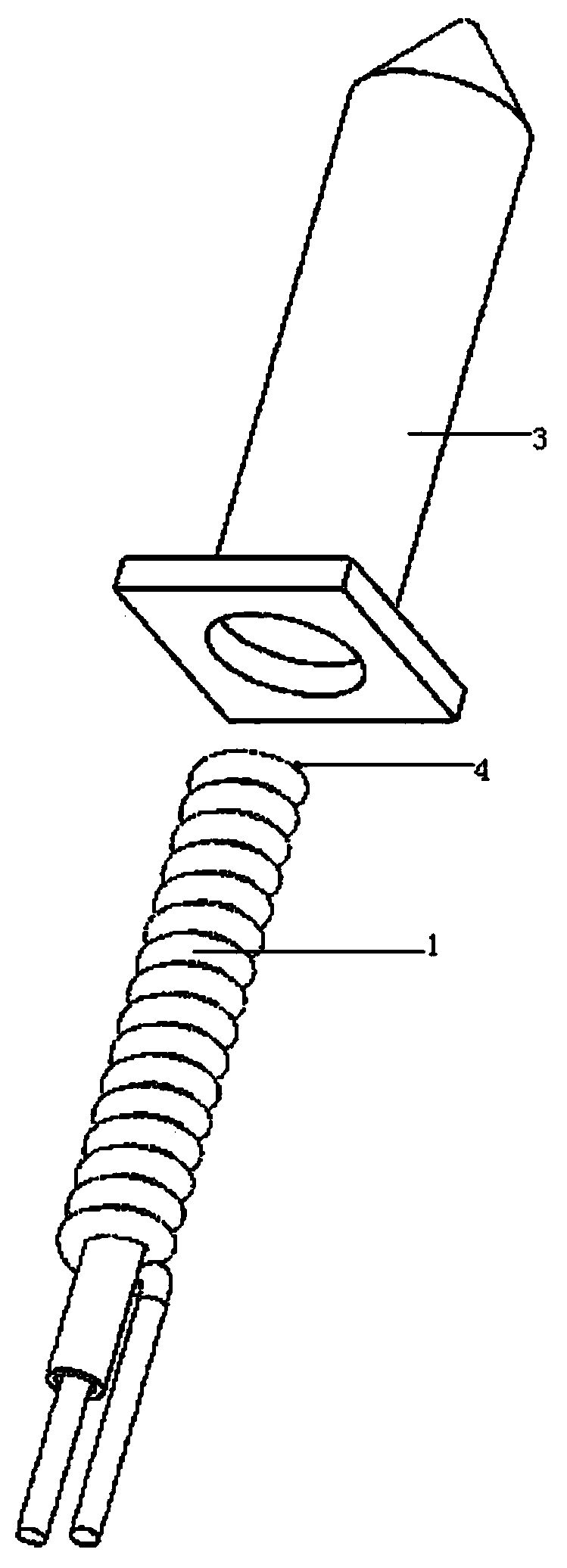

[0020] figure 1 As shown in , the low-temperature bake-not-burn electronic cigarette heating element and constant temperature control device include the electronic cigarette heating element, and also have bistable switching circuits Q4, Q5, heating constant temperature circuit U1, conversion circuit U2, and electronic cigarette heating element. The heating wire RT is also used as a thermocouple. The bistable switch circuits Q4, Q5, the heating constant temperature circuit U1, and the conversion circuit U2 are installed on the internal circuit board of the electronic cigarette. The positive pole of the lithium battery G in the electronic cigarette body and the bistable switch circuit Q4, Q5, the positive power input end of the conversion circuit U2 are connected by wires, the positive power output end of the conversion circuit U2 and the second positive power input end of the heating constant temperature circuit U1 are connected by wires, the bistable switch circuit Q4, Q5 power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com