Ceiling transfer system and ceiling transfer car

A technology for handling systems and moving vehicles, which is applied in the field of ceiling handling systems and ceiling moving vehicles, and can solve problems such as difficulty in increasing the number of items and limited number of loading parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

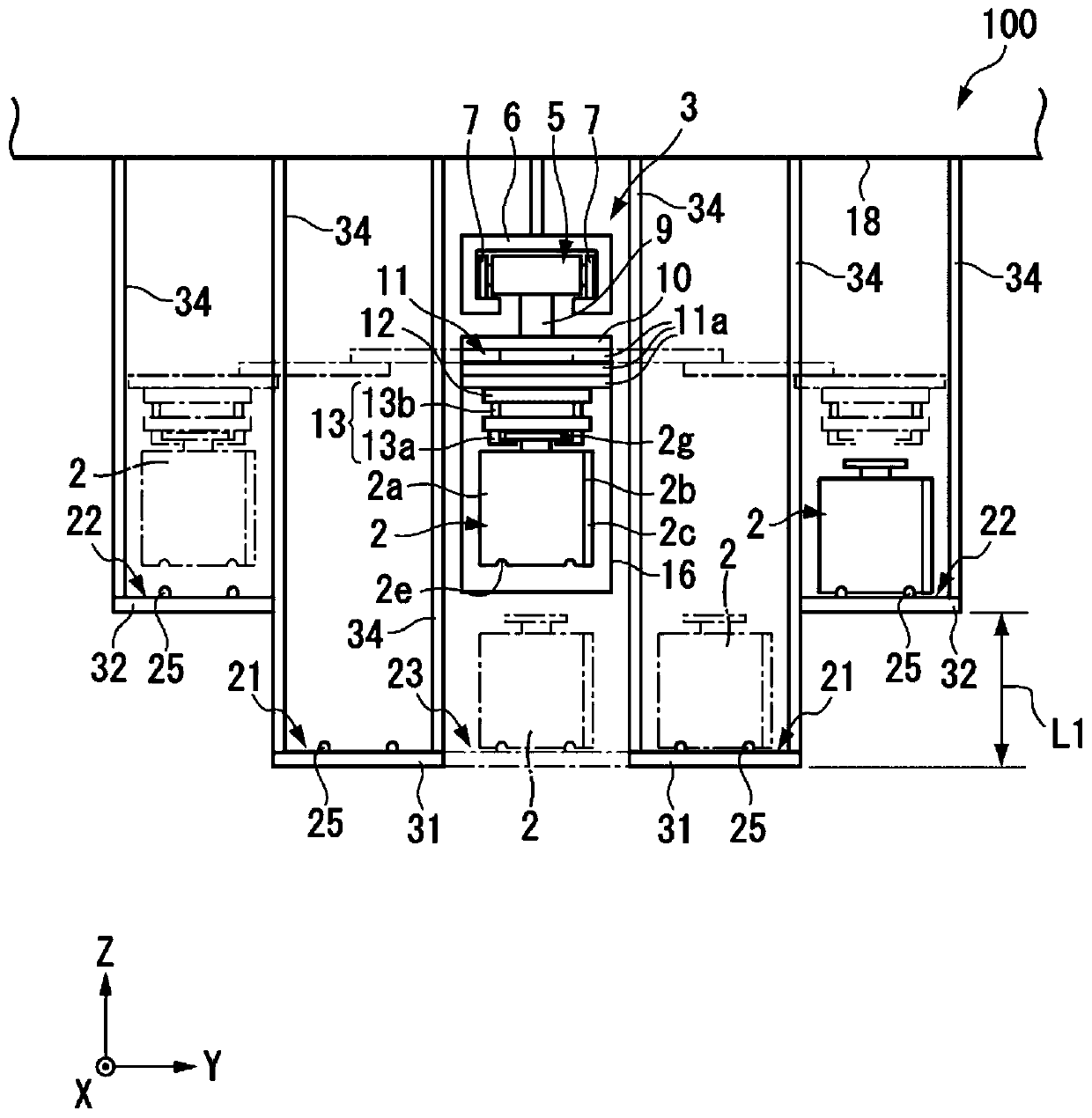

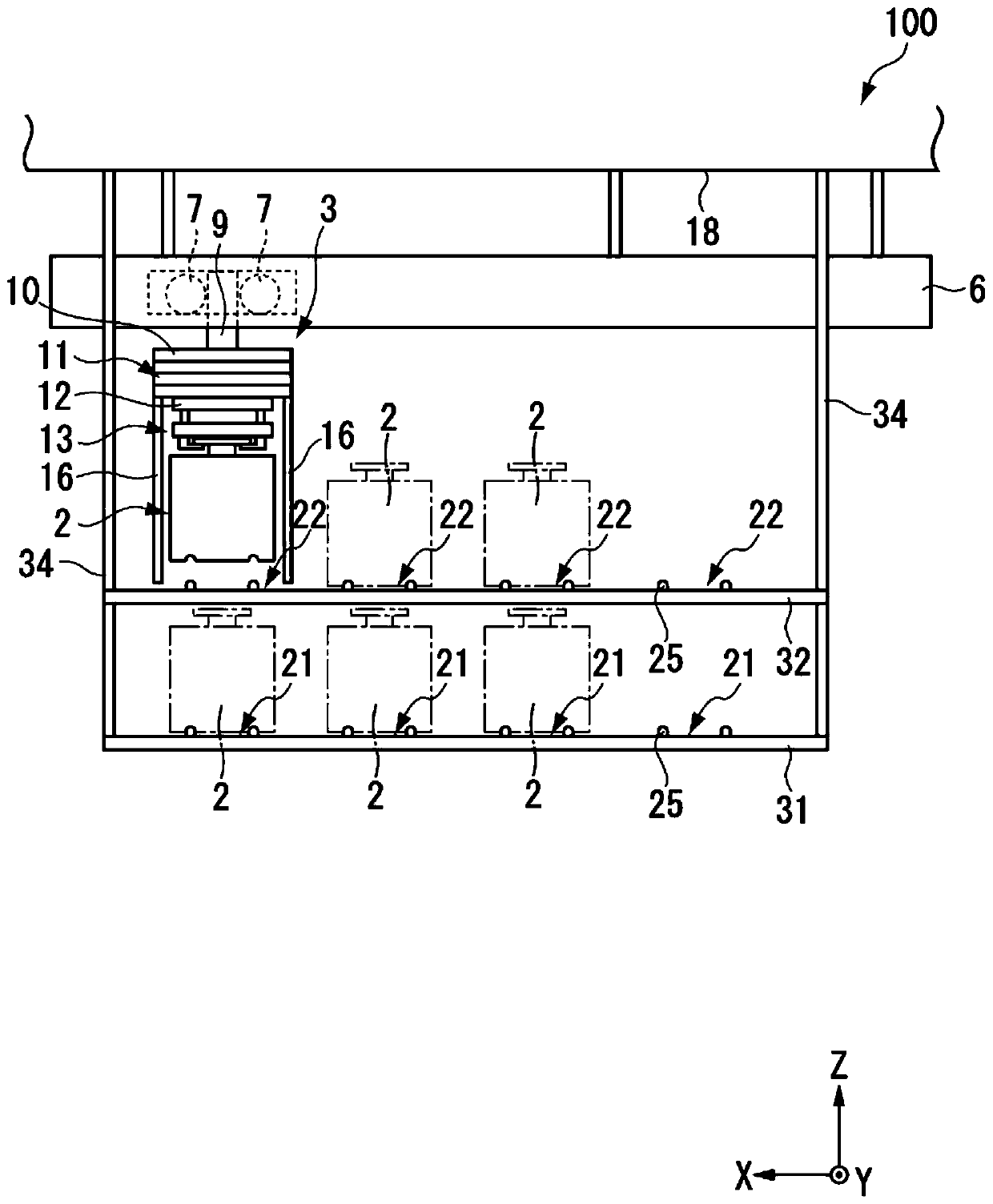

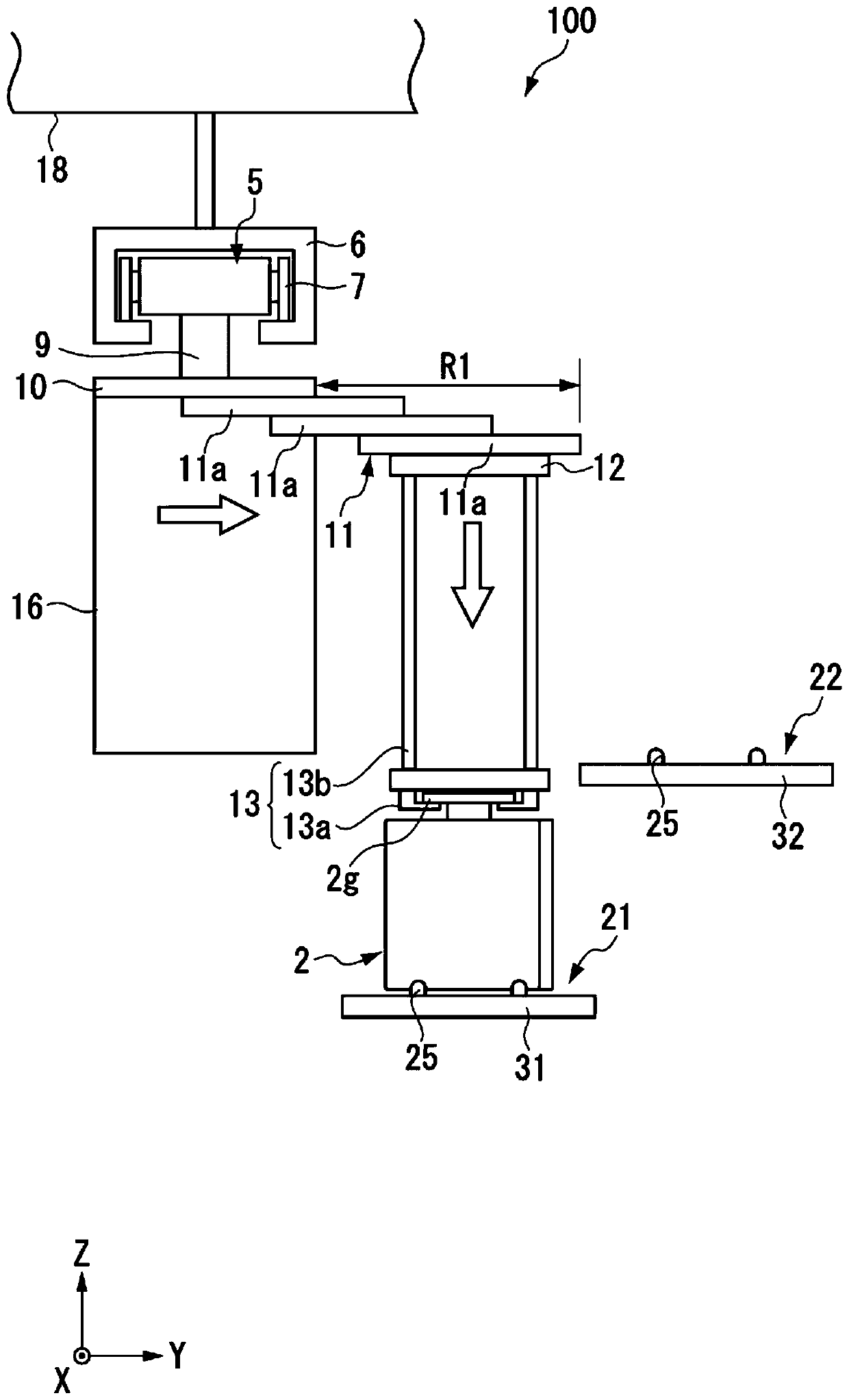

[0025] figure 1 as well as figure 2 It is a figure which shows an example of the ceiling conveyance system 100 which concerns on 1st Embodiment. figure 1 is the main view, figure 2 is a side view. The ceiling transport system 100 includes a ceiling transport vehicle 3 , a first loading unit 21 , a second loading unit 22 , and a third loading unit 23 . The ceiling conveyance system 100 is installed in, for example, a semiconductor device manufacturing factory. The ceiling transport system 100 can hold and transport the article 2 by the ceiling transport vehicle 3 , and can also place the article 2 on the first loading unit 21 , the second loading unit 22 , and the third loading unit 23 by using the ceiling transport vehicle 3 . , and keep item 2. In addition, in the present embodiment, whether or not to provide the third mounting portion 23 is optional, so figure 1 is represented by a single dotted line.

[0026] The article 2 is, for example, a transport container for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com