Stay cable force measuring device and measuring method therefor

A measuring device and cable technology, applied in the direction of tension measurement, etc., can solve the problems of poor versatility and practicability, difficulty in determining the best working point, measurement error, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

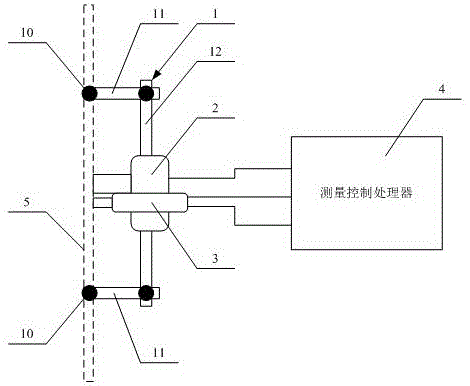

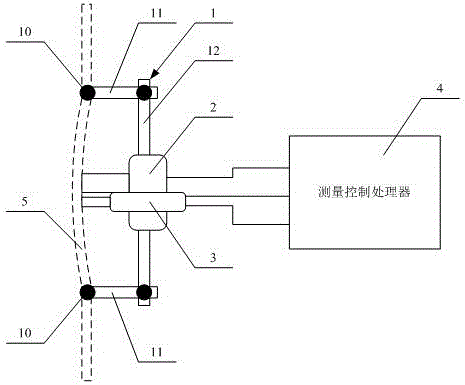

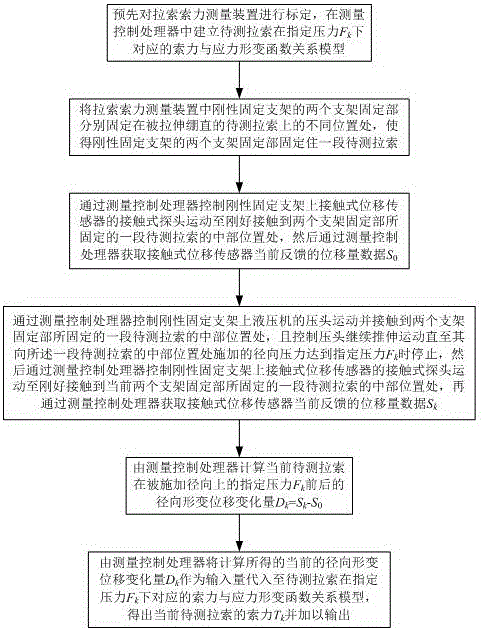

[0044] The invention provides a cable force measuring device, which is used to measure the cable force by being installed on the cable to be tested, such as figure 1 As shown, the cable force measuring device includes a rigid fixed support 1 , a hydraulic press 2 , a contact displacement sensor 3 and a measurement control processor 4 . Wherein, the rigid fixed bracket 1 has two bracket fixing parts 10 for being respectively fixed at different positions on the cable 5 to be measured, and the hydraulic machine 2 and the contact displacement sensor 3 are fixedly installed on the two brackets through the rigid fixed bracket 1 . 10 and is located at the side of the line connecting the two bracket fixing parts, and the pressure head of the hydraulic machine 2 and the contact probe of the contact displacement sensor 3 can be located along the middle position of the connecting line of the two bracket fixing parts. expand and contract in the vertical direction, so that the hydraulic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com