Diaphragm pumps for fluidizing and conveying powders

一种膜片式、粉末的技术,应用在用于弹性流体的泵送装置的部件、变容式泵部件、液体变容式机械等方向,能够解决大小或者说尺寸获得等问题,达到涂油均匀、的磨损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

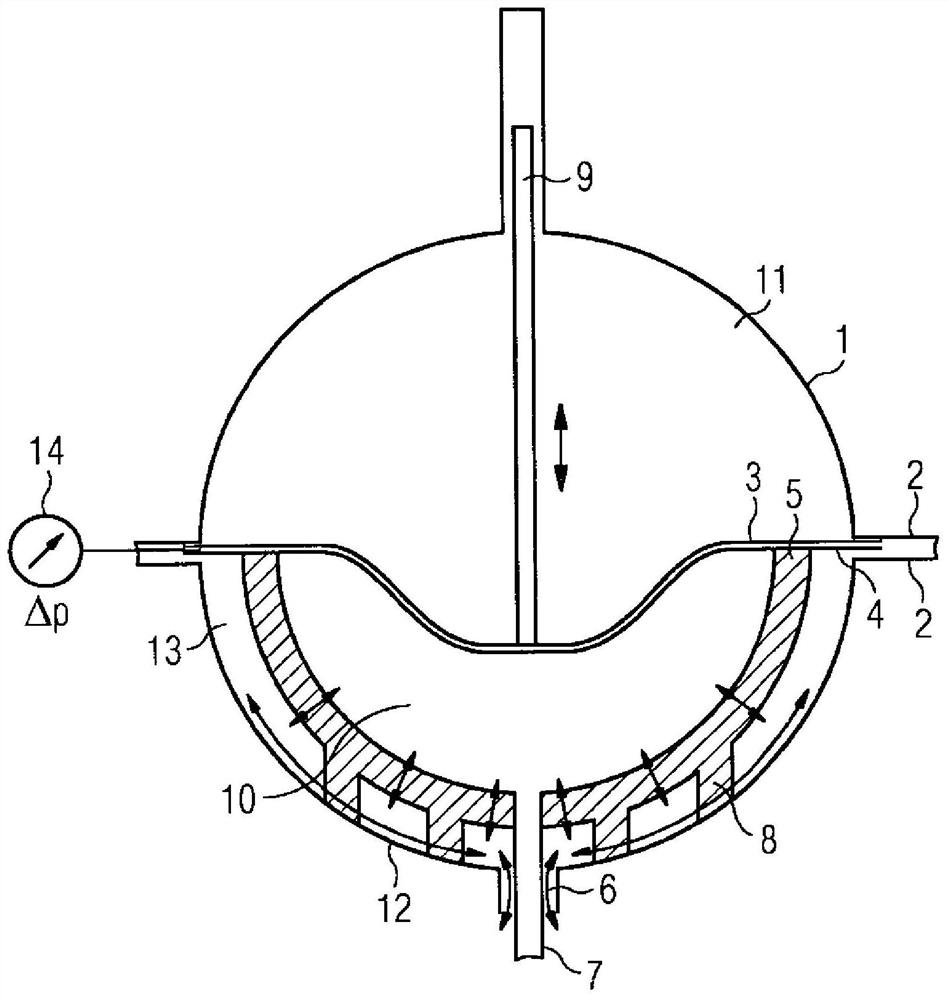

[0014] exist figure 1 The diaphragm pump shown in is a device comprising two pressure-resistant half shells 1 , 12 which are gas-tightly connected to each other via a flange connection 2 . In addition to the simple assembly possibilities of the powder pump, the flange connection also has the additional function of fixing and clamping the membrane 3 and the loose surface 5 via the filter flange 4 . Due to the spherical geometry, the membrane can thus be deflected advantageously and in a manner that preserves the filter material into the powder chamber in the form of a paraboloid of revolution. In this case, the deflection of the diaphragm is brought about by the force action of the hydraulic fluid, as described, for example, in DE 10 2016 201 182 . Jumpy changes are avoided and a substantially flat contact of the membrane 3 against the half-shell-shaped loose surface 5 can be achieved after the delivery process has ended. A small dead volume can be achieved by this advantageo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com