Transformation core and phase reversal transformation using the same

A technology of transformers and magnetic cores, applied in the direction of transformer/inductor magnetic cores, transformers, transformer/inductor components, etc., can solve the problems that the invention is difficult to realize, and achieve the effects of reducing the number of components, high efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

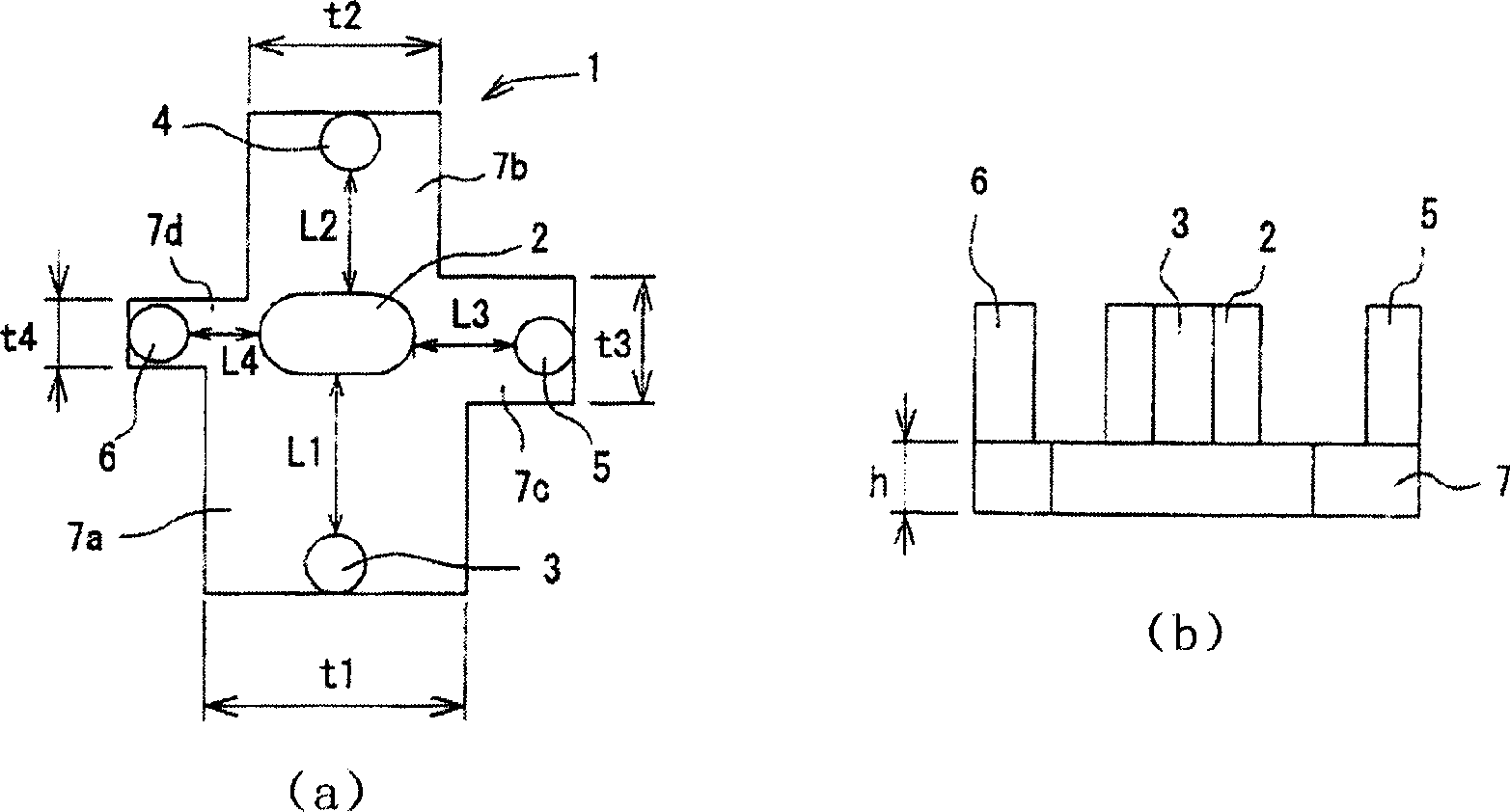

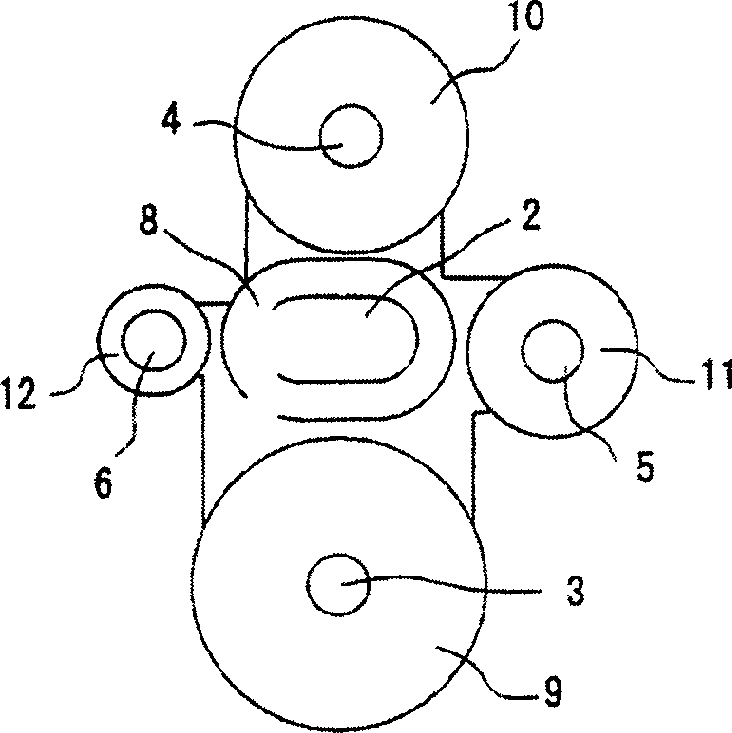

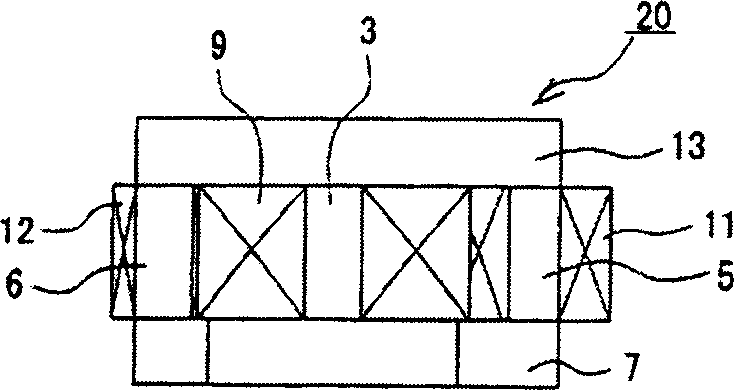

[0035] The following describes the transformer core and the inverter transformer according to the present invention with reference to the accompanying drawings.

[0036] figure 1 (a) and (b) show an example of the transformer core (iron core) concerning this invention. In the iron core 1 of this embodiment, the primary coil leg 2 is arranged at the center, and three or more (here four are arranged) secondary coil legs 3, 4, 5, 6 are arranged around the periphery. The connecting plates 7 are magnetically combined.

[0037] These primary coil legs 2 , secondary coil legs 3 , 4 , 5 , 6 and connecting plate 7 are all made of ferrite material and integrated by sintering or other methods. As the ferrite material, any ferrite material such as Mn—Zn ferrite can be used. However, in order to improve performance, it is preferable to use ferrite materials with less iron loss, higher saturation magnetic flux density and excellent soft magnetic properties.

[0038] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com