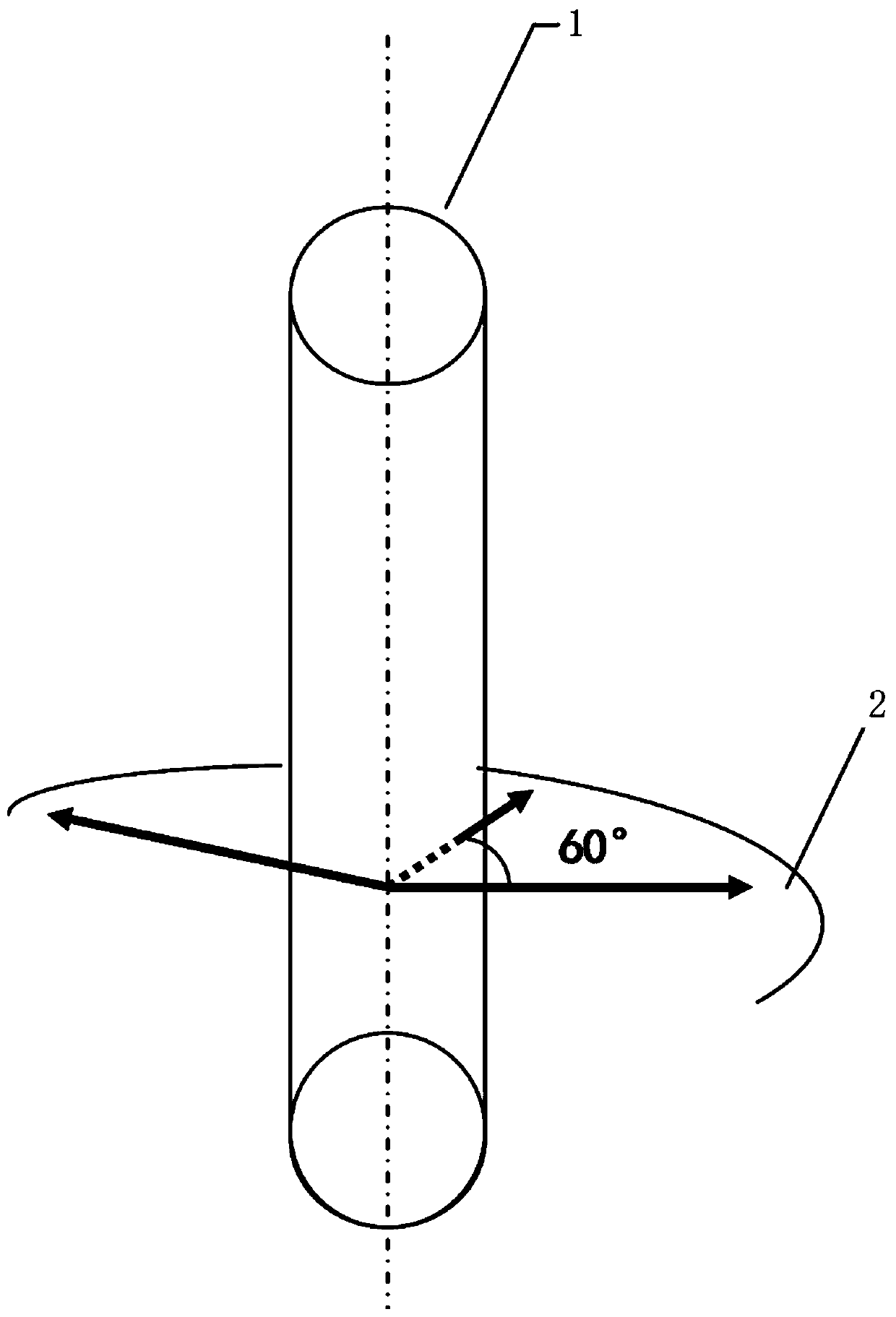

Perforation fracturing method for longitudinal residual oil dig-down of old well of single-sand body oil reservoir

A single sand body, remaining oil technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as affecting fracturing effect and oil drainage area, uncontrollable fracture direction, and insignificant production stimulation effect. , to achieve good production stimulation effect, low cost, and prevent the rise of water cut in oil wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] In July 2016, this technology was tested in Well Wang**. The stress difference between the two phases of the reservoir level was 4.5MPa, and the net pressure required to open natural fractures was 3-5MPa. The lower part of the oil layer was perforated and fractured. Use 0.3% cross-linking liquid + 0.6%-0.8% degradable fiber + rigid temporary plugging agent with multiple particle size difference (2mm, 3mm, 4mm) + 20 / 40 mesh low density selective wettability proppant (1.5g / cm 3 ) composed of fracturing working fluid, after temporarily plugging into new fractures, the surface construction pressure rose from 8.9MPa to 22.0MPa, the pressure increased by 13.1MPa, and the net pressure of bottomhole pressure monitoring increased by 8.0MPa, realizing the opening and filling of natural fractures, expanding Drainage area, DSI pre- and post-pressure monitoring results show that the fracture height is under control, and the lower oil layer of the well has been fully stimulated; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com