Drill rod spiral composite drilling machine for building

A drill pipe and helical technology, which is applied in the field of drill pipe helical composite drilling rigs and construction technology, can solve the problems of heavy weight, low efficiency, and the failure of the clamping pile reinforcement cage to reach the bottom, etc., and achieve the effect of smooth and firm hole walls and hole formation Good, the effect of reducing power load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

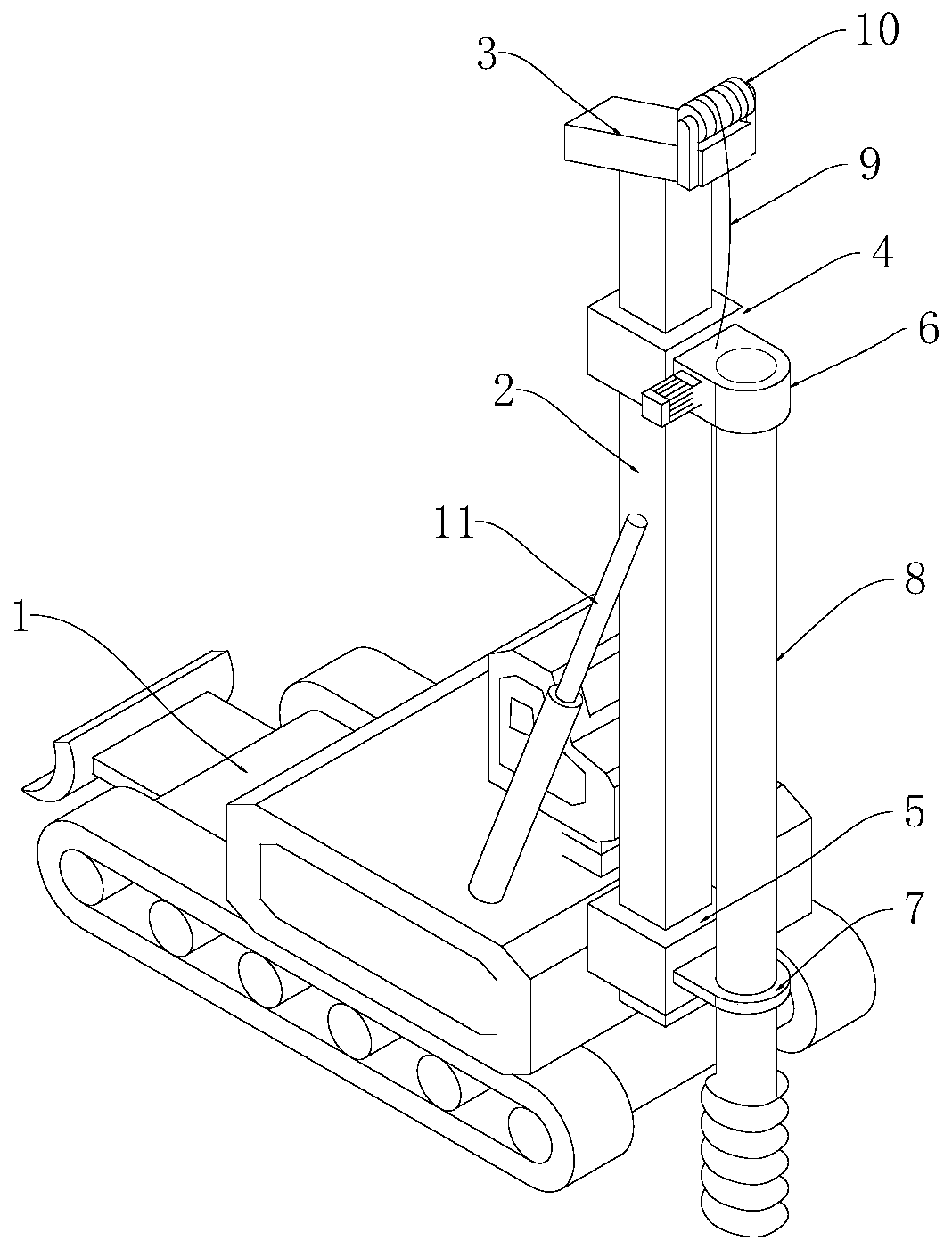

[0032] Such as Figure 1 to Figure 9 , the present invention is a drill pipe helical compound drilling rig and construction technology, comprising:

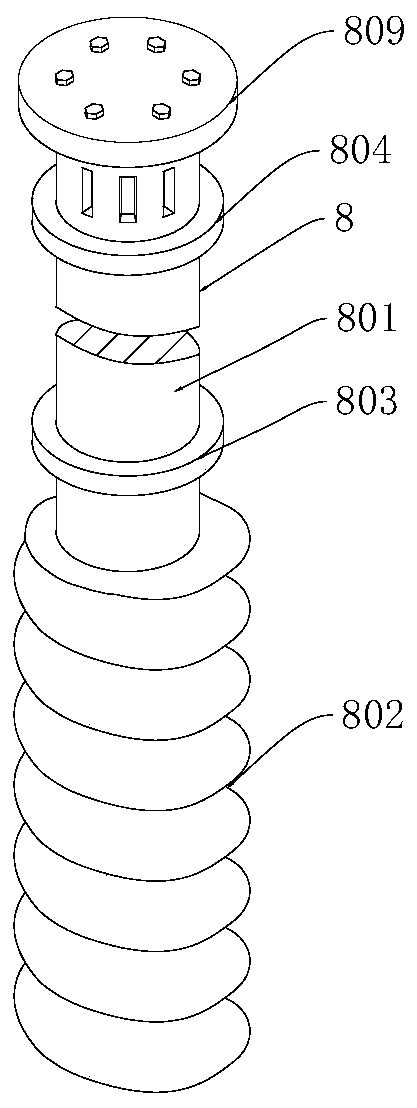

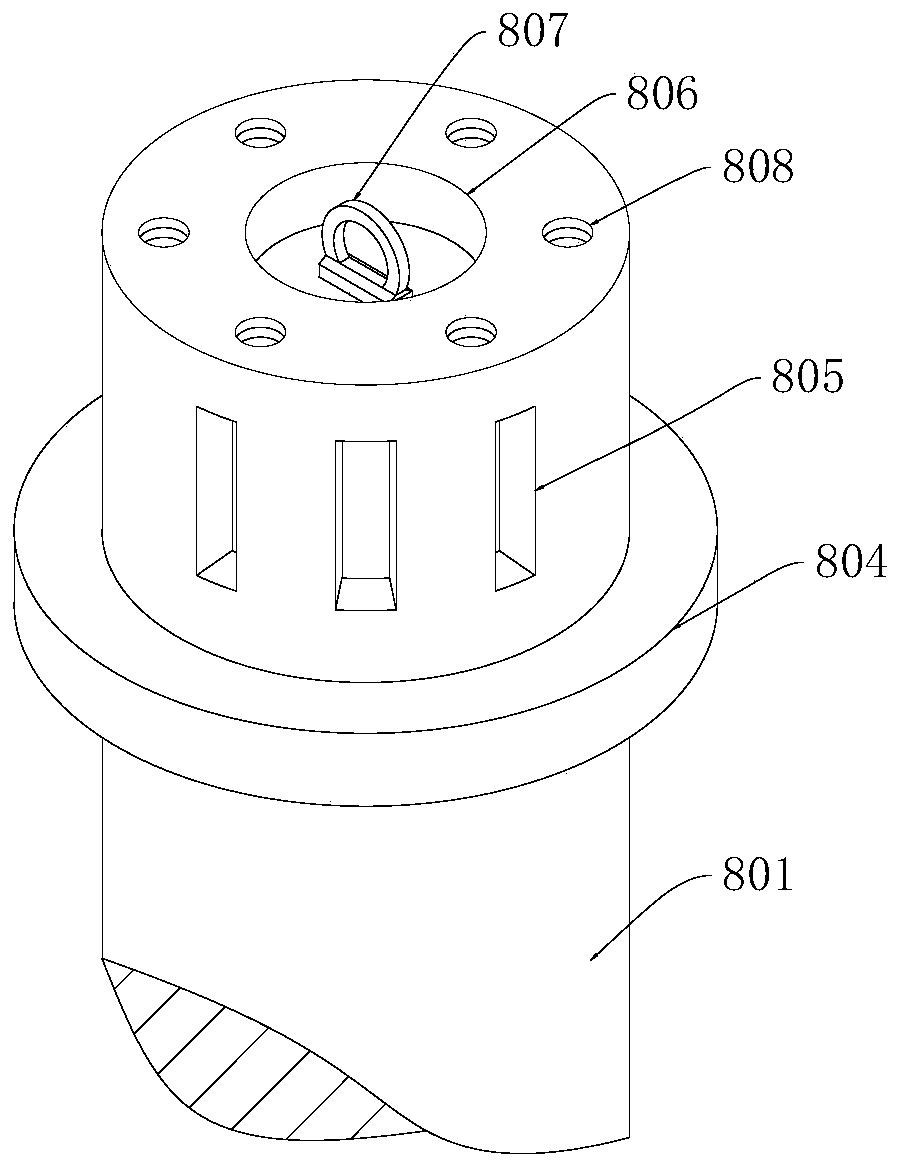

[0033] Car body 1, a column 2 is arranged on the car body 1, an installation block 3, a movable block 4 and a fixed block 5 are arranged on the column 2, a driving mechanism 6 and a limit sleeve 7 are respectively arranged on the movable block 4 and the fixed block 5, The middle part of the limit sleeve 7 is sleeved with a screw mechanism 8;

[0034] The driving mechanism 6 includes a housing 601, a worm 602, a worm wheel 603, a first through hole 604, a limit block 605, a second through hole 606, bolts 607 and a top support plate 608, and the housing 601 is fixedly connected to the outside of the movable block 4 , the worm 602 is arranged on one side inside the casing 601 and the worm 602 can rotate by itself, the worm wheel 603 is arranged on the other side inside the casing 601, and the worm wheel 603 is engaged with the worm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com