Planet flat die granulator

A granulator and flat die technology, which is applied in the direction of die extrusion granulation, presses, manufacturing tools, etc., can solve the problems of difficult control of material humidity, slippage and stop, large energy consumption, etc., to improve production efficiency, avoid The effect of skid stop and power load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

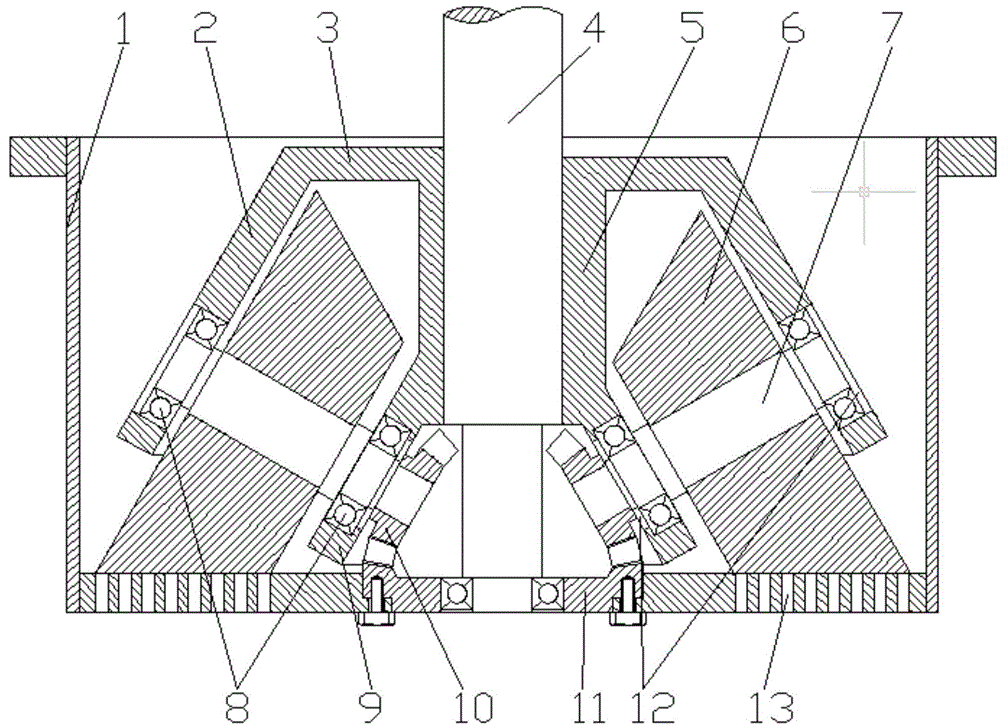

[0017] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure, the planetary flat die granulator of the present invention includes a material storage cylinder 1 for containing materials and a coaxially arranged material storage cylinder 1 to allow the materials to be extruded The extruding assembly of particles is formed by the container; the bottom of the container is provided with an extrusion hole 13;

[0018] The extruding assembly includes at least one extruding roller 6 with a truncated conical structure for extruding materials, and an extrusion roller 6 for fixedly installing the extruding roller 6 and driving the extruding roller 6 to revolve around the axis of the container 1 At the same time, the planetary transmission mechanism rotates, the tapered surface of the extruding roller 6 is tangent to the inner surface of the bottom of the container 1 and the axis of the extruding roller 6 is coplanar with the axis of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com