Combined compressing apparatus

A compression equipment, combined technology, applied in mechanical equipment, variable displacement pump components, rotary piston pumps, etc., can solve problems such as large size and increased power load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

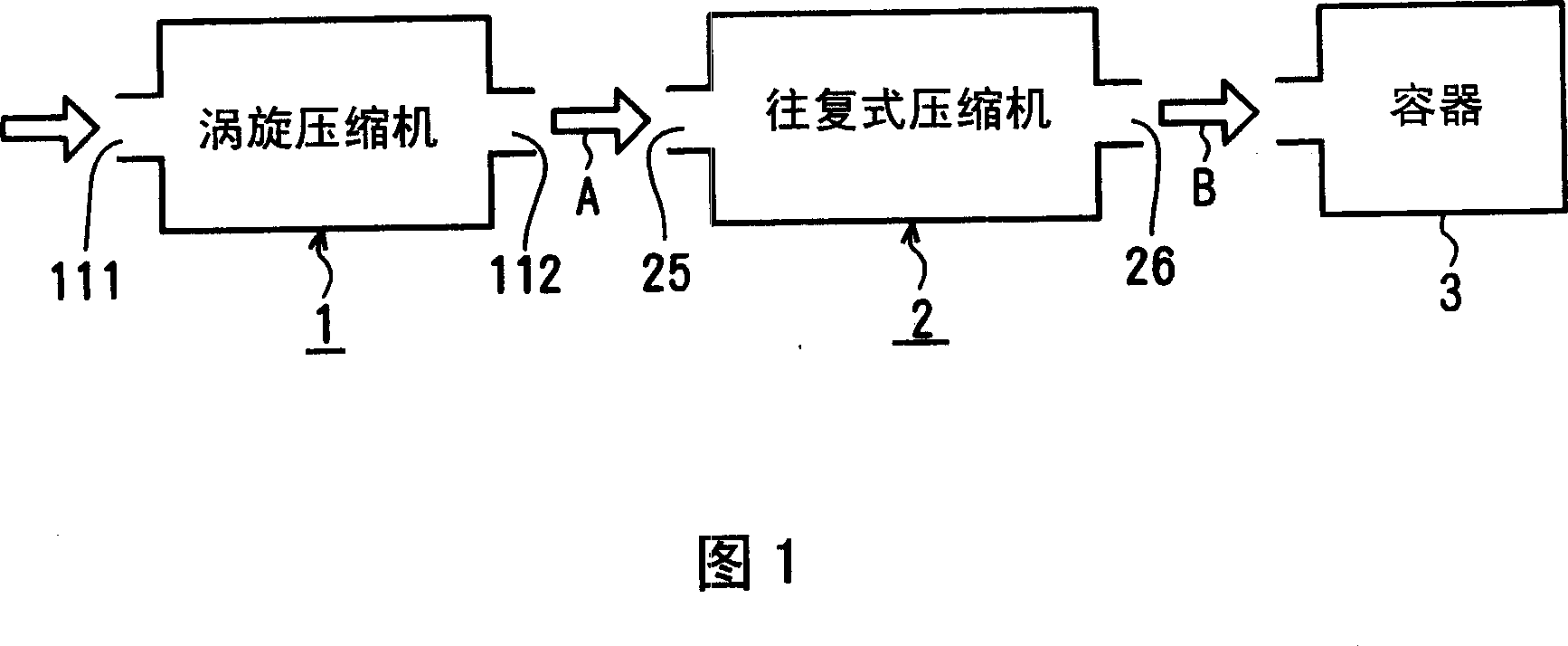

[0009] As shown in FIG. 1, in the combined compressor (combined compressor) according to the present invention, a scroll compressor 1 which is excellent in noiselessness and saves energy is used as an upstream compressor, and has a simple structure and can provide high-pressure reciprocating compressors. Compressor 2 is used as the downstream compressor. The primary compressed gas A compressed by the scroll compressor 1 is delivered to the reciprocating compressor 2 , wherein the primary compressed gas A is further compressed by the reciprocating compressor into a high-pressure secondary compressed gas B to be delivered to the container 3 .

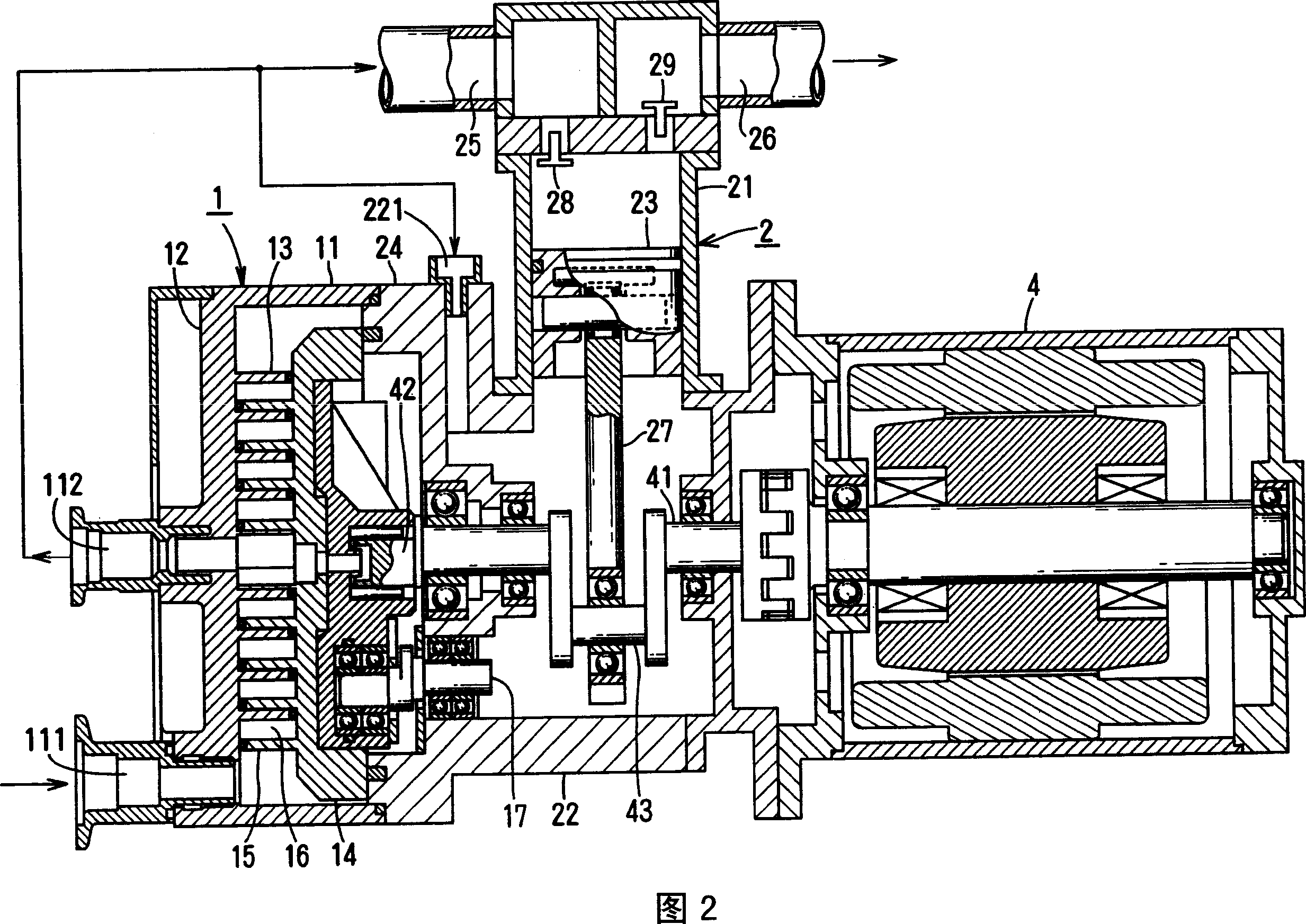

[0010] In FIG. 2 a first embodiment of a combined compression apparatus is shown, wherein the rear part of the cylindrical housing 11 of the scroll compressor 1 is fixed to the front part of the crankcase 22 of the reciprocating compressor 2 . A single engine 4 is mounted to the rear of the crankcase 22 . The engine 4 functions as a powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com