A shale intercalation inhibitor made of ultra-low molecular weight branched tertiary amine polyamine

A molecular weight, tertiary amine type technology, used in the preparation of amino compounds from amines, organic chemistry, drilling compositions, etc., can solve the problems of entanglement, uneven coating, inhibition performance limitation, repeated adsorption, etc. The effect of wall instability, improvement of inhibition performance, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using diethylenetriamine and dimethylallylamine as raw materials, the ultra-low molecular weight branched tertiary amine polyamine is prepared by a step-by-step synthesis method, and the specific steps are as follows:

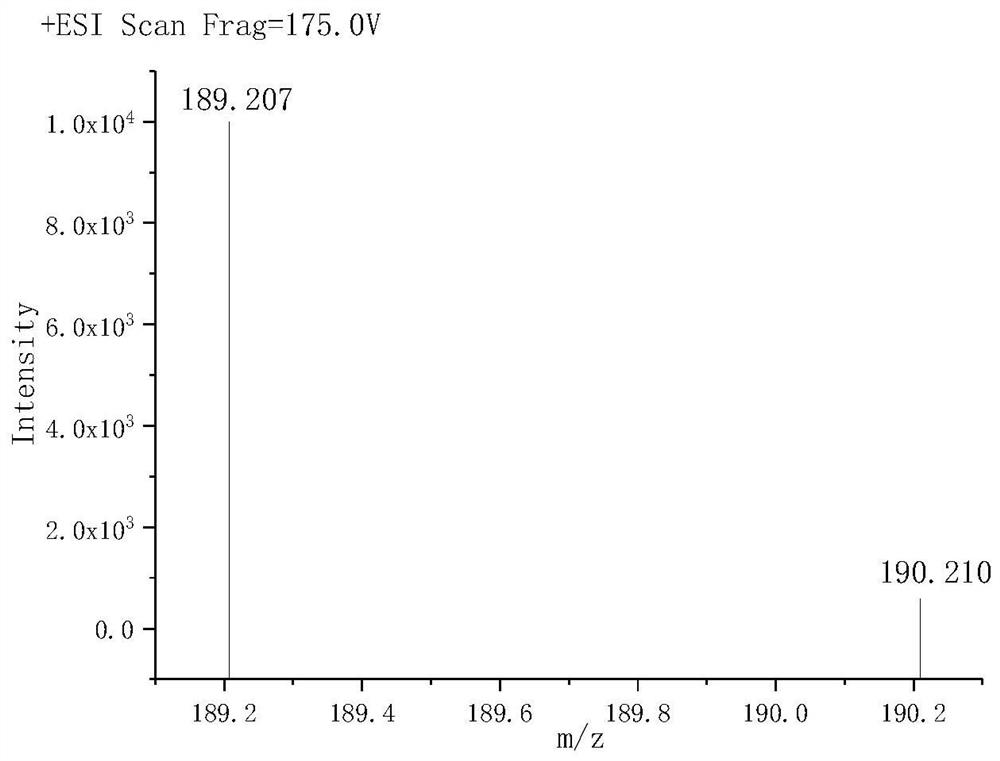

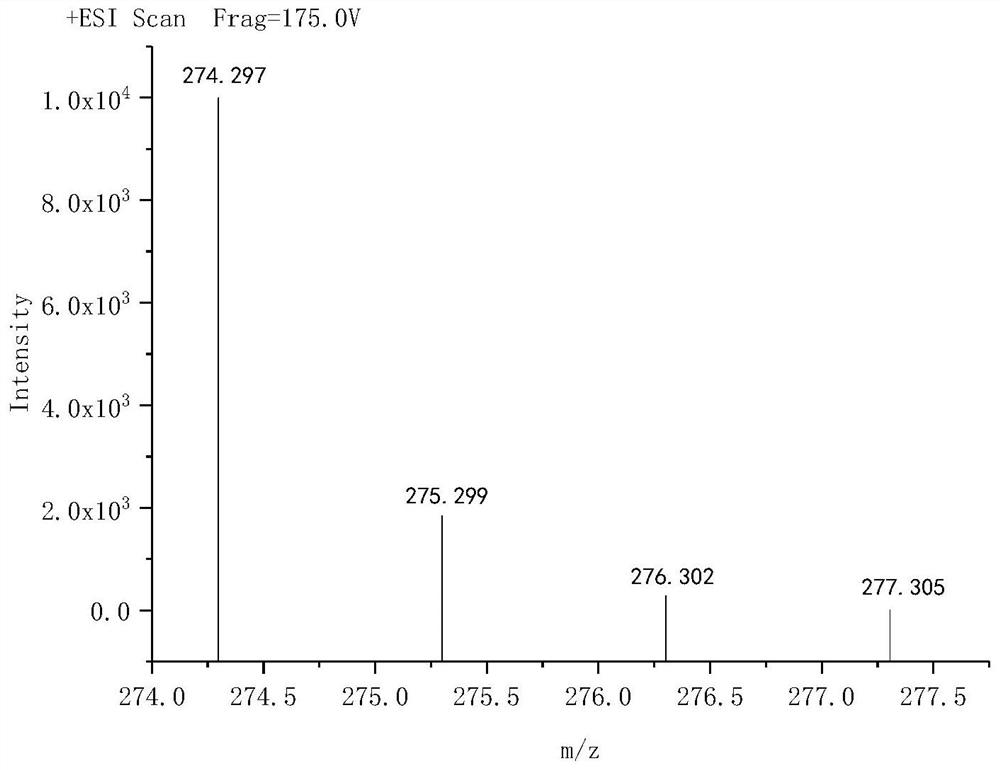

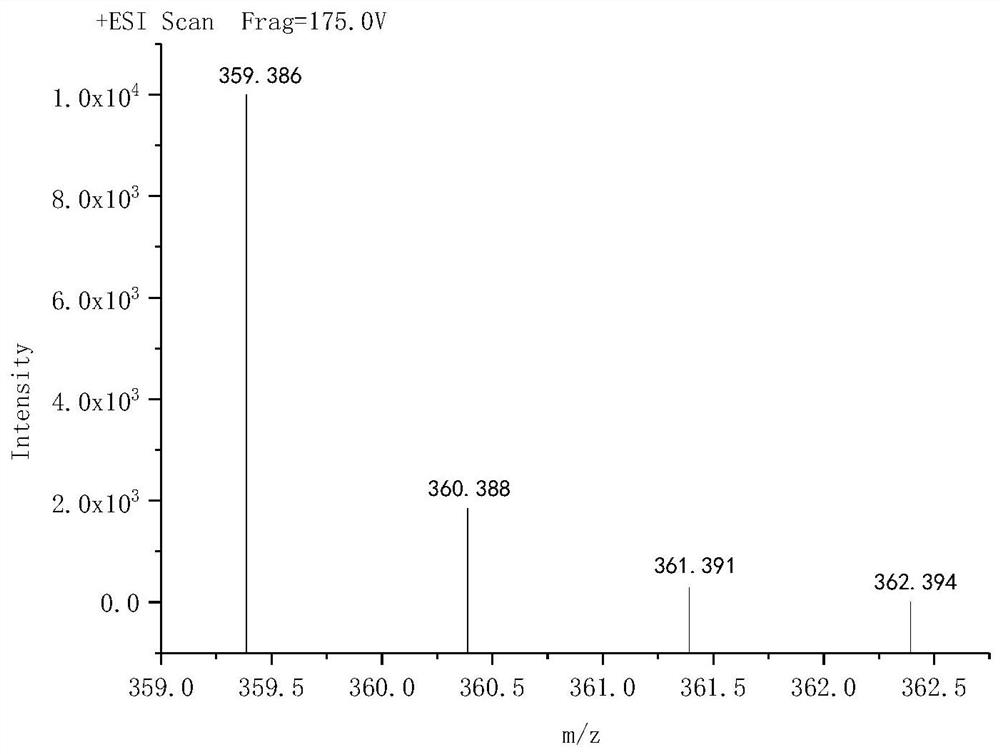

[0036] (1) Synthesis of G1 ultra-low molecular weight branched tertiary amine polyamine: Accurately weigh 0.1 mole of diethylenetriamine and 0.1 mole of dimethylallylamine and dissolve them in 80 mL of anhydrous methanol respectively, and diethylenetriamine Transfer the methanol solution of dimethyl allylamine to a round bottom flask, and slowly add the methanol solution of dimethylallylamine into the round bottom flask with a constant pressure separatory funnel at 25°C and stir. After the dropwise addition, heat up Heat to reflux for 8 hours at 95°C. After the reaction, use a rotary evaporator to evaporate the solvent at 105°C and an absolute vacuum of less than 3000Pa to obtain G1 ultra-low molecular weight branched tertiary amine polyamine. The molecu...

Embodiment 2

[0047] Using diethylenetriamine and dimethylallylamine as raw materials, a one-pot method is used to prepare ultra-low molecular weight branched tertiary amine polyamines. The specific steps are as follows

[0048] Accurately weigh diethylenetriamine and dimethylallyl with a molar ratio of 1:5 and dissolve them in 100mL of anhydrous methanol respectively, and diethylenetriamine is 0.1 mole, and the dimethyl The methanol solution of allylamine was added dropwise to the methanol solution of diethylenetriamine. After the dropwise addition, the temperature was raised to 100°C, and the reaction was heated under reflux for 12 hours. Distill under reduced pressure and evaporate the solvent to obtain G5 ultra-low molecular weight branched tertiary amine polyamine. Molecular formula of G5 ultra-low molecular weight branched tertiary amine polyamine: Molecular formula of G5 ultra-low molecular weight branched tertiary amine polyamine: C 29 h 68 N 8 , exact molecular weight: 528.557, ...

Embodiment 3

[0051] Using ethylenediamine and dimethylallylamine as raw materials, the ultra-low molecular weight branched tertiary amine polyamine is prepared by a step-by-step synthesis method, and the specific steps are as follows:

[0052] (1) Synthesis of G1 ultra-low molecular weight branched tertiary amine polyamine: Take 0.1 mole of ethylenediamine and 0.1 mole of dimethylallylamine and dissolve them in 80 mL of anhydrous methanol respectively, transfer the methanol solution of ethylenediamine to Add the methanol solution of dimethylallylamine to the round bottom flask at 25°C using a constant pressure separatory funnel slowly into the round bottom flask and stir. After the dropwise addition, heat up to 95°C. Heat to reflux for 8 hours. After the reaction is completed, use a rotary evaporator to evaporate the solvent at 105° C. and an absolute vacuum of less than 3000 Pa to obtain G1 ultra-low molecular weight branched tertiary amine polyamine. The molecular formula of G1 ultra-low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com