Preparation method of silicon nitride magnesium powder

A technology of magnesium silicon nitride and powder, applied in nitrogen and non-metallic compounds, etc., can solve the problems of high energy consumption, long production cycle, and easy product residues, etc., and achieves low energy consumption, high production efficiency, and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

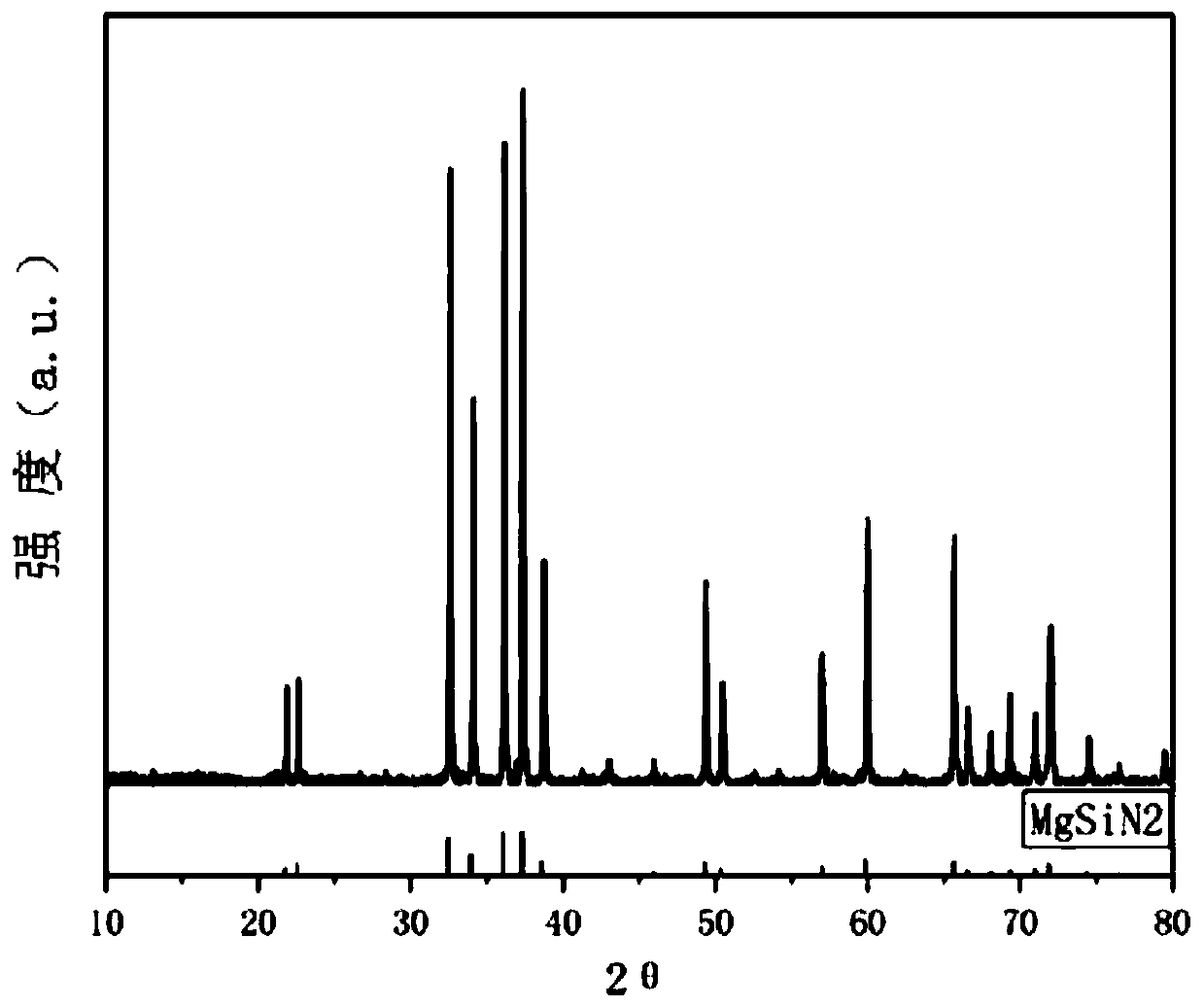

Image

Examples

Embodiment 1

[0036] Prepare magnesium silicon nitride powder according to the following steps:

[0037] (1) Mix 200-mesh magnesium nitride powder and 200-mesh silicon powder according to the mass ratio of 20%:80%, and then mix them with absolute ethanol whose mass is 0.8 times that of the raw material powder. Mill on a ball mill for 2 hours to achieve uniform mixing; then vacuum-dry at 80°C, and pass through a 50-200 mesh sieve after drying to obtain a mixed powder;

[0038] (2) Continuously add 0.5% urea of the mixed powder mass obtained in step (1) into the mixed powder, uniformly mix in a rolling ball mill for 2 minutes, then loosely pack it in a porous graphite boat, and place it in the combustion synthesis equipment , after vacuuming, fill it with 1MPa high-purity nitrogen, use titanium powder as the ignition agent, and use the electrified tungsten coil to heat the reactant to ignite the ignition agent to induce the combustion synthesis reaction; after the combustion reaction, the g...

Embodiment 2

[0041] Prepare magnesium silicon nitride powder according to the following steps:

[0042] (1) Take the raw materials according to the weight ratio, 200 mesh magnesium nitride powder is 50%, 200 mesh silicon powder is 50%; after mixing with absolute ethanol whose quality is 1.0 times of the raw material powder quality, use silicon nitride balls as the medium , milled on a planetary ball mill for 2 hours to achieve uniform mixing; then vacuum-dried at 80°C, and passed through a 50-200 mesh sieve after drying to obtain a mixed powder;

[0043] (2) Continuously add 10% urea of the mass of the mixed powder obtained in step (1) into the mixed powder, uniformly mix it in a rolling ball mill for 4 minutes, then loosely pack it in a porous graphite boat, and place it in the combustion synthesis equipment , after vacuuming, fill it with 1MPa high-purity nitrogen, use titanium powder as the ignition agent, and use the electrified tungsten coil to heat the reactant to ignite the igniti...

Embodiment 3

[0046] Prepare magnesium silicon nitride powder according to the following steps:

[0047] (1) Take the raw materials according to the weight ratio, 200 mesh magnesium nitride powder is 80%, 200 mesh silicon powder is 20%, after mixing with absolute ethanol whose quality is 1.2 times of the raw material powder quality, use silicon nitride ball as the medium , milled on a planetary ball mill for 2 hours to achieve uniform mixing; then vacuum-dried at 80°C, and passed through a 50-200 mesh sieve after drying to obtain a mixed powder;

[0048](2) Add urea with 20% mass of the mixed powder obtained in step (1) into the mixed powder in stages, mix uniformly for 50 seconds in a rolling ball mill, then loosely pack it in a porous graphite boat, and place it in the combustion synthesis equipment Inside, after vacuuming, fill it with 1MPa high-purity nitrogen gas, use titanium powder as the ignition agent, and use the electrified tungsten coil to heat the reactant to ignite the ignitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com