Belt sorting machine

A kind of sorting machine and belt-type technology, which is applied in the direction of sorting, conveyors, conveyor objects, etc., and can solve problems such as limited contact area between rollers and goods, relatively high size requirements for sorted goods, and goods stuck between rollers, etc. , to achieve the effect of improving independence, increasing contact area, and smooth cargo sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

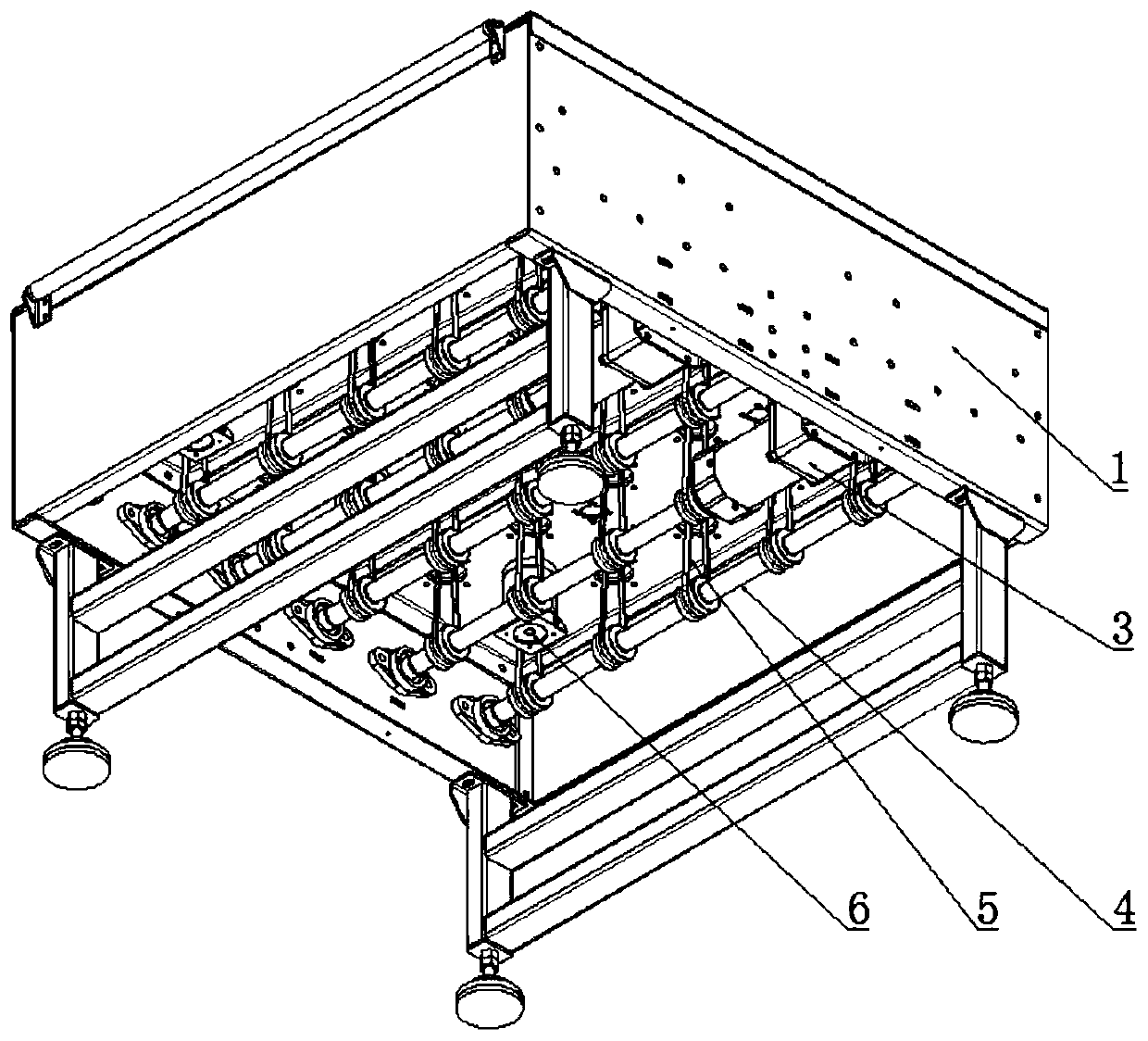

[0044] Example 1

[0045] A belt sorter includes a frame 1. A number of sorting units 2 are arranged uniformly on the working surface of the frame 1. The sorting unit 2 includes a deflection seat 201, which can rotate around the axis of the deflection seat 201, A conveyor belt 202 is provided on the deflection seat 201, and the working surface of the conveyor belt 202 is higher than the top surface of the deflection seat 201.

[0046] In this embodiment, a plurality of sorting units 2 constitute a reversing work surface, and the conveyor belt 202 on each sorting unit makes the goods move forward under the action of the conveyor belt. The rotation of the deflection seat 201 around its axis realizes the reversal of the sorting unit, thereby changing the conveying direction of the goods. Compared with the existing oblique wheel sorting unit, the contact area between the conveyor belt and the goods is significantly increased, and the goods sorting is smoother. At the same time, it can...

Example Embodiment

[0047] Example 2

[0048] On the basis of the above-mentioned embodiment, the deflection seat 201 includes a fixed frame body 2011, the top surface of the fixed frame body 2011 is provided with a receiving groove, and the conveyor belt 202 is arranged in the receiving groove. The fixed frame body 2011 includes a 凵-shaped frame body, the top of the frame body is fixed with a circular panel by screws, and a conveyor belt support body is fixed between the trunnions on both sides of the frame body. The bottom of the fixed frame 2011 is fixedly provided with a rotating pulley 2012, and the rotating pulley 2012 can drive the fixed frame 2011 and the conveyor belt 202 to rotate around the axis of the rotating pulley 2012.

[0049] In this embodiment, the deflection seat 201 includes a fixed frame body, the frame of the fixed frame volume sorting unit, the conveyor belt 202 is installed and supported on the fixed frame body, and the fixed frame body 2011 also bears the weight of the goods....

Example Embodiment

[0050] Example 3

[0051] Based on the above embodiment, the conveyor belt 202 includes a guide wheel 2021, a guide wheel 2022, a belt 2023, and a driving device that drives the belt to rotate around a guide wheel 2021 and a guide wheel 2022 that are hinged on the deflection seat; One 2021, the second guide wheel 2022 partially protrudes from the top surface of the deflection seat 201, and the axes of the first guide wheel 2021 and the second guide wheel 2022 are parallel and located on the same horizontal plane.

[0052] In this embodiment, the first guide wheel 2021 and the second guide wheel 2022 play a guiding role, so that the belt moves the goods forward while circulating around the guide wheel 2021 and the second guide wheel 2022 to realize the sorting of the goods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com