Steel coil packing station and control method

A technology of packaging workers and steel coils, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of unfavorable packaging costs, low utilization rate of packaging stations, waste of packaging consumables, etc., to reduce time-consuming and labor costs, Improve the efficiency of packaging operations, improve the effective operation rate and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

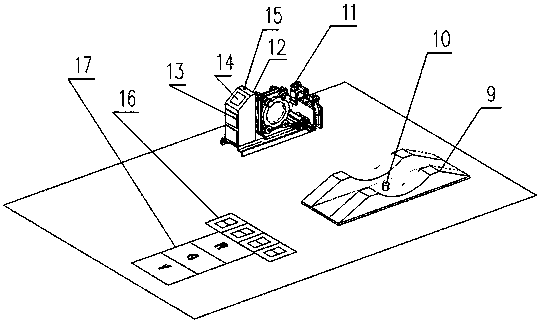

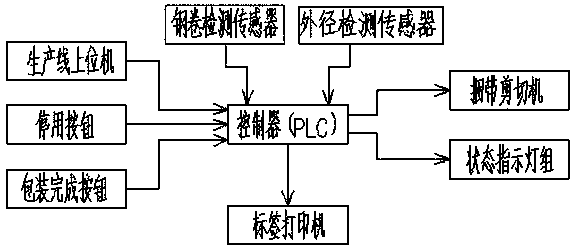

[0028] Embodiment 1: refer to Figure 1-5 As shown, a steel coil packaging station includes a packaging saddle 9, a strapping cutter 11, a control cabinet 12, a label printer 13, a countdown display 16, and an operation status indicator group 17 arranged in an L shape, wherein the packaging The specification of saddle 9 is to weld two saddle-shaped steel billets along the length direction on a 1600×800mm steel plate with a thickness of 20mm. 9. A steel coil detection sensor 10 is arranged at the center of the bottom to detect whether there is a steel coil stored on the saddle; The cabinet 12 is arranged adjacent to the strapping cutter 11, and a label printer 13 is arranged in the middle part, and a man-machine interface and a controller (PLC) are arranged in the upper and lower parts respectively; The strap shearing machine 11 is equipped with two strap storage boxes and a cutting channel, which can automatically cut steel straps of different widths and thickness specificati...

Embodiment 2

[0029] Embodiment 2: refer to Figure 1-5 , a steel coil packaging station operation method, comprising the following steps:

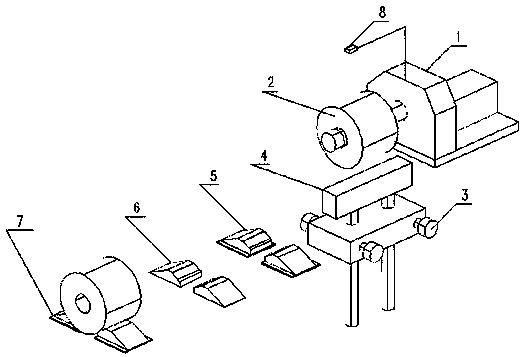

[0030] 1) The steel coil to be packaged is hoisted in, and after the coiler 1 at the exit of the production line coils the steel coil 2, the coil unloading trolley 3 removes the steel coil 2 from the coiler 1 by upgrading the saddle 4, and the steel coil 2 is weighed After being weighed at the weighing position 5 and bundled at the bundling position 6, it is delivered to the hoisting position 7 by the coil unloading trolley 3, and then the crane driver closest to the steel coil lifts the steel coil from the hoisting position 7 and delivers it to the coil packaging operation area , the driver looks for the packaging station where the green light of the status indicator group 17 in the packaging operation area is on (ready) or the countdown is close to zero, and the steel coil 2 to be packaged is hoisted into the packaging saddle 9 of the green light stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com